High-black-brightness scratch-resistant PMMA/ASA alloy material and preparation method thereof

An alloy material, black and bright scratch-resistant technology, applied in the field of composite materials, can solve the problems that the surface scratch resistance is difficult to meet the requirements of automobile factories, and the surface scratch resistance is difficult.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

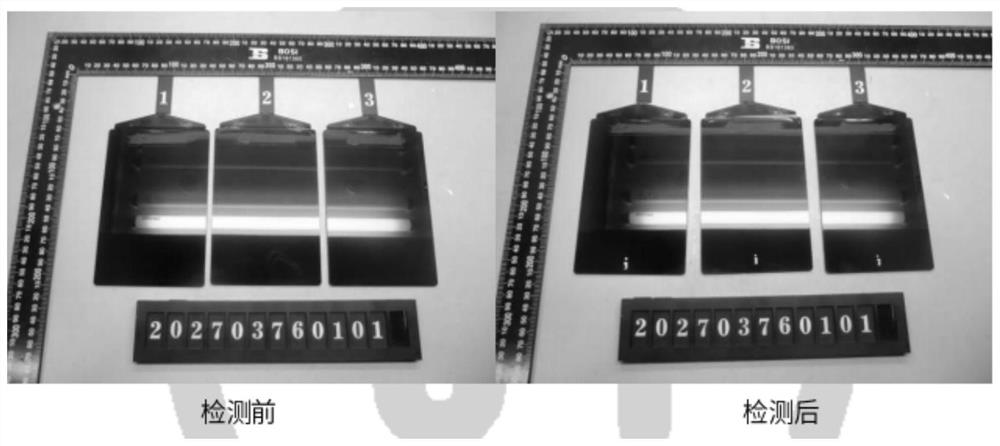

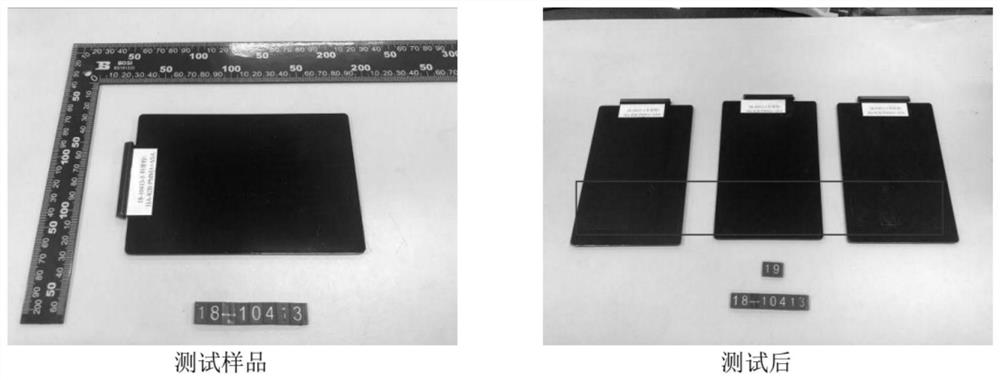

Image

Examples

Embodiment

[0030] The formula is shown in Table 1. Among them, the melting index of ASA resin is 20g / 10min; the melting index of PMMA resin is 10g / 10min; the toughening agent is butyl acrylate, methyl methacrylate, acrylonitrile, and styrene copolymer, which is a core-shell structure, Japan Mitsubishi SX-006; in the modifier, by mass percentage, long-chain ternary copolymer nylon (source: TM126, Shandong Guangyin) is 20%, phenyl silicone oil (source: KF-50-1000cs, Shin-Etsu) is 30% , fumed alumina (source: Guangzhou Jibisheng) is 50%; carbon black pre-dispersed masterbatch, the weight concentration of carbon black is 55%, the carrier is PETs, which has excellent dispersibility, and the primary particle size of carbon black is 10 ~100nm; processing aids are antioxidant (1010), anti-ultraviolet agent (UV234), lubricant (Korean Shinwon Chemical EBS) at a weight ratio of 1:1:1. All raw materials are conventional commercially available products.

[0031] Table 1 embodiment, comparative exam...

Embodiment 5

[0038] The modifier in Example 1 was replaced with 50% long-chain ternary copolymerized nylon, 20% phenyl silicone oil, and 30% fumed alumina (by mass percentage), a total of 4.5 parts, and the rest remained unchanged to obtain an ASA / PMMA alloy , the cross scratch ⊿L is 1.28; the gloss (20° angle) is 79; the color blackness L value is 24.1.

Embodiment 6

[0040] In Example 1, the weight parts of toughening agent, processing aid, and carbon black masterbatch were adjusted to 4:1.5:5 to obtain ASA / PMMA alloy, and the cross scratch ⊿L was 1.19; gloss (20° angle) is 79; the color blackness L value is 24.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com