Anti-leakage construction method suitable for horizontal expansion joint

A construction method and horizontal expansion and contraction technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of increased material loss, manual construction period, difficult to fit closely with embedded angle steel, and narrow operating surface of expansion joints. The effect of avoiding leakage repair construction operations, reducing leakage repair costs, and simplifying the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

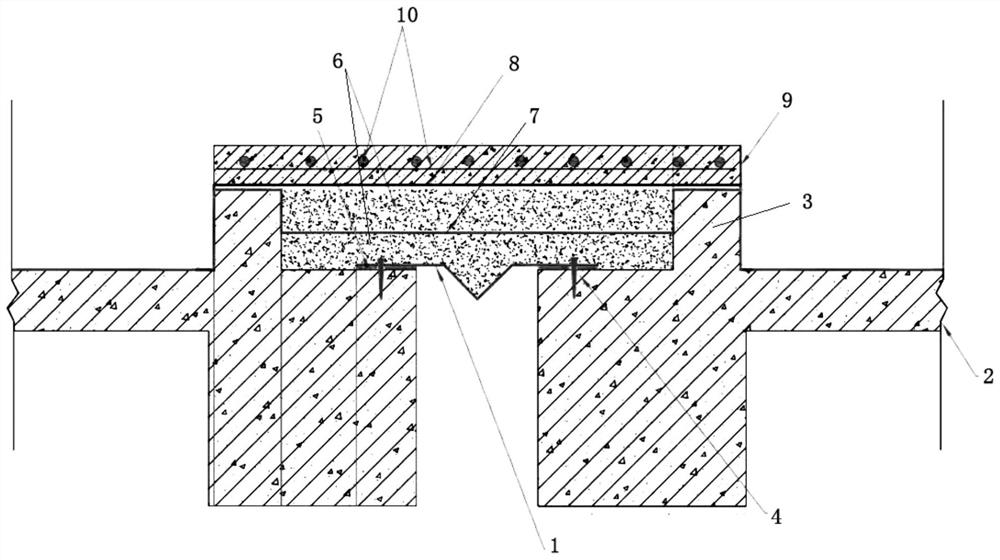

[0030] Embodiment 1: It is suitable for the case where the height of the main structure on both sides of the expansion joint is equal,

[0031] Such as figure 1 As shown, first, when pouring the floor structural beam formwork, a concrete structure reverse sill 3 is poured at a distance of 130mm from the floor main structure 2 to the edge of the expansion joint. The length of the concrete structure reverse sill 3 is the same as the length of the expansion joint, and the width of the concrete structure 100mm, height 80mm, the top surface of the concrete structure anti-sill 3 is polished. After the main structure is capped, clean the base layer of the structural surface at the expansion joints, and paint the two-component polysulfide sealant 5 with a width of 50mm on the floor structural surface on both sides of the expansion joint twice, and the two-component polysulfide sealant 5 Thickness 1mm~1.5mm; Anchor the V-shaped galvanized iron plate 1 with a horizontal edge of 1.5mm o...

Embodiment 2

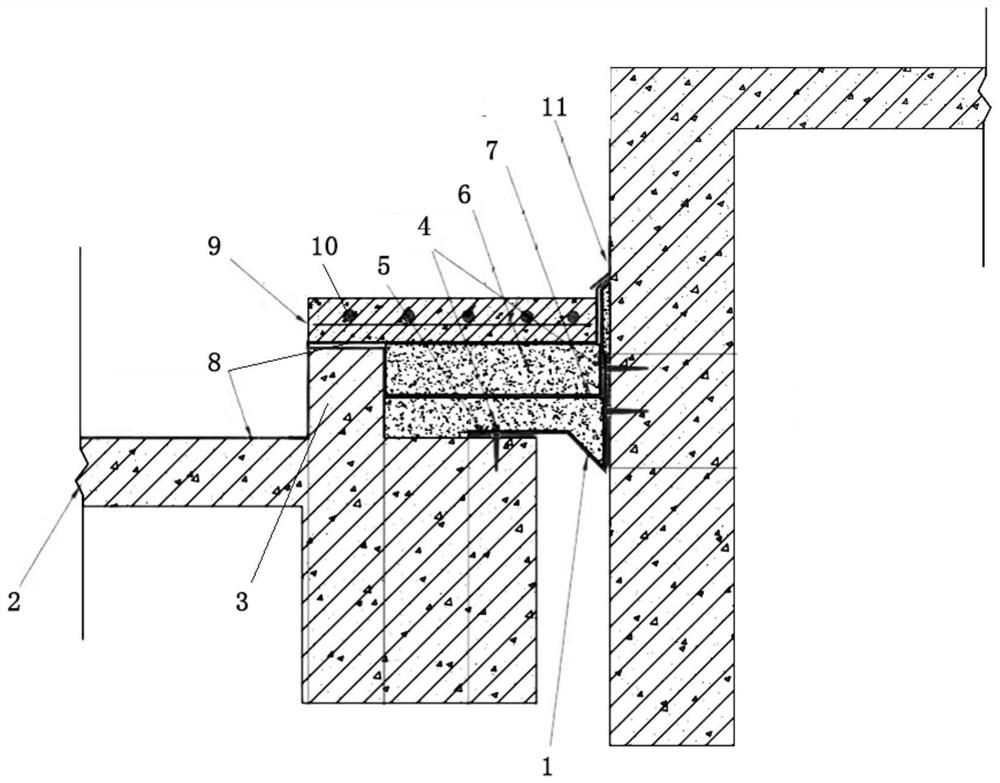

[0032] Embodiment 2: Applicable to the case where there is a difference in height between the main structures on both sides of the expansion joint,

[0033] Such as figure 2 As shown, in the construction of the expansion joint, first, when the floor structure beam slab is closed and poured, on the floor structure on the lower side, a concrete structure anti-sill 3 is poured at a distance of 130mm from the edge of the expansion joint, and the concrete structure The length of the anti-sill 3 is the same as the length of the expansion joint, the width of the anti-sill 3 of the concrete structure is 100mm, and the height is 80mm, and the top surface of the anti-sill 3 of the concrete structure is polished. After the main structure is capped, clean the base layer of the structural surface at the expansion joints, and apply a 50mm wide two-component polysulfide sealant twice on the edge of the floor structure on the lower side of the structure. On the wall, brush two-component pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com