Efficient drying device for powdered rock phosphate pellet production

A drying device and powder pellet technology, applied in the field of phosphorus chemical industry, can solve the problems of waste of phosphate rock resources, not advanced enough, and phosphate rock crisis, etc., and achieve the effects of reducing heat loss, increasing production capacity, and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

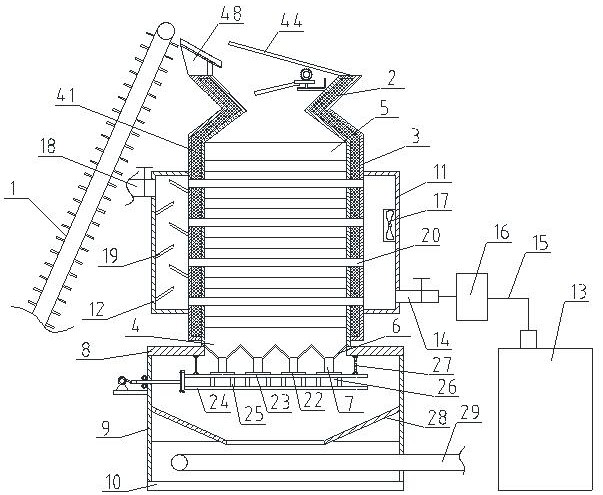

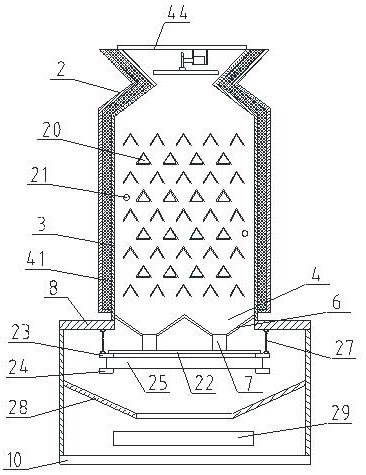

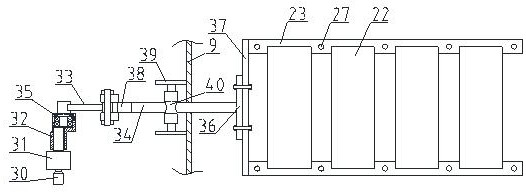

[0024] The present invention will be further described below in conjunction with the examples and accompanying drawings, but the present invention is not limited in any way. Any transformation or replacement based on the teaching of the present invention belongs to the protection scope of the present invention.

[0025]Such as Figure 1~4 As shown, a high-efficiency drying device for the production of phosphate rock powder pellets according to the present invention includes a feeding mechanism 1, a drying tower body, a feeding mechanism and a heating mechanism, and the drying tower body includes from top to bottom The feed section 2, the drying section 3 and the discharge section 4 are arranged in sequence, the feed section 2 includes a first transition section and a second transition section, and the first transition section is a structure with a large upper end and a small lower end, The second transition section is a structure with a small upper end and a larger lower end, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com