Open-loop stepping servo controller, servo control system and servo control method

A technology of servo controller and stepping motor, which is applied in the field of servo control, can solve the problems of accelerating the damage speed of valve position sensor, wearing the conductive layer of the substrate in the working area, and threatening the safe operation of the process system, so as to improve the response speed and realize automation Manage and eliminate the effect of high failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

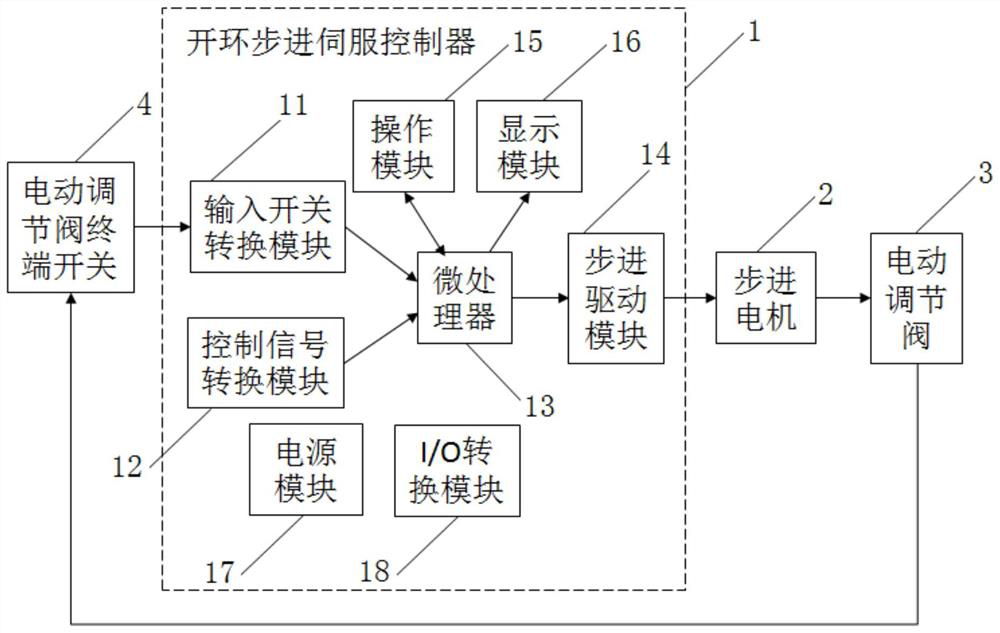

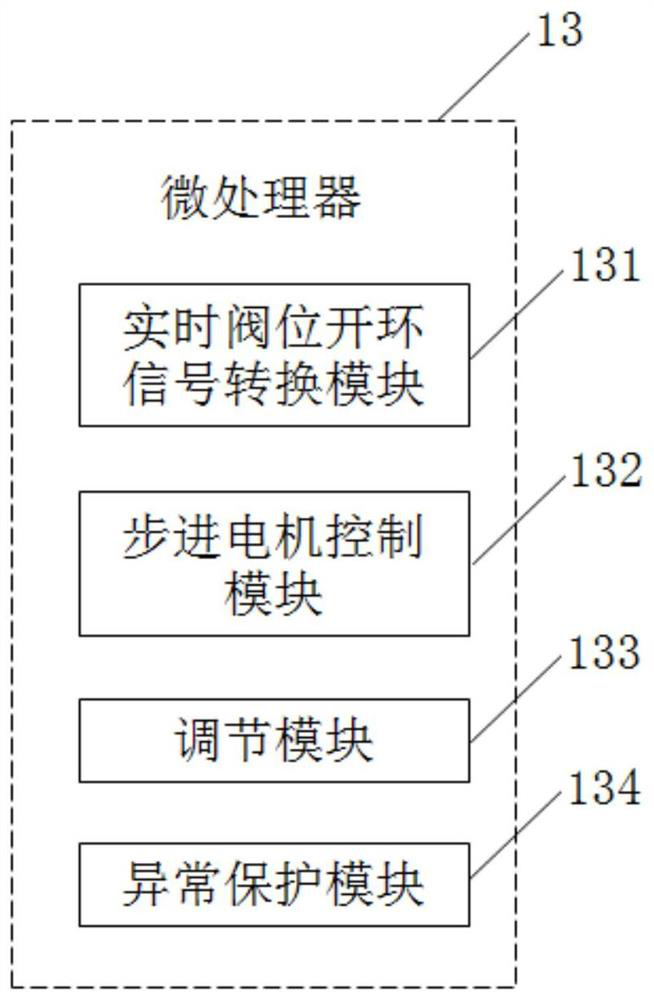

[0045] like Figure 1-2 As shown, an open-loop step servo controller provided by the present invention includes: an input switch conversion module 11, a control signal conversion module 12, a microprocessor 13, a step driver module 14, and an operation module 15 , a display module 16, a power supply module 17 and an I / O conversion module 18, and the microprocessor 13 includes a real-time valve position open-loop signal conversion module 131, a stepper motor control module 132, an adjustment module 133 and an abnormality protection module 134.

[0046] The input switch conversion module 11 is connected with the microprocessor 13, and is used to collect the open and close position signal of the terminal of the electric control valve; the control signal conversion module 12 is connected with the microprocessor 13, and is used for converting the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com