A kind of positive plate and battery

A positive electrode sheet and positive active material technology, applied in the field of positive electrode sheets and batteries, can solve the problems of high energy density and good cycle performance, and achieve good cycle performance, avoid energy density and high energy density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] An embodiment of the present invention provides a method for preparing a positive electrode sheet.

[0040] The preparation method of positive plate comprises:

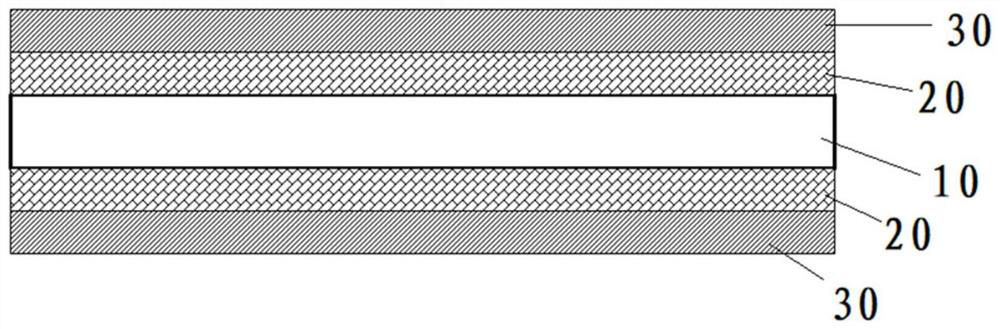

[0041] providing a current collector 10;

[0042] forming a transition layer 20 on at least one side surface of the current collector 10;

[0043] Forming an active layer 30 on the surface of the transition layer 20 away from the current collector 10;

[0044] Wherein, the transition layer 20 includes nickel-cobalt-manganese ternary material particles, and the active layer 30 includes positive electrode active material particles; wherein, the thickness ratio of the transition layer 20 on the same side of the current collector 10 and the active layer 30 is 1:20- 1:2; the shortest distance from the largest particle of the nickel-cobalt-manganese ternary material particles in the transition layer 20 on the same side of the current collector 10 to the current collector 20 is L1, and the nickel in the transition l...

Embodiment 1

[0057] Preparation of positive electrode sheet:

[0058] Disperse nickel-cobalt-manganese ternary material particles, binder PVDF (polyvinylidene fluoride), and conductive carbon black in N-methylpyrrolidone to obtain a uniform transition layer slurry; in the transition layer slurry, the solid component contains 85wt % lithium iron phosphate, 10wt% binder PVDF and 5wt% conductive carbon black;

[0059] Lithium cobaltate, binder PVDF and conductive carbon black are dispersed in N-methylpyrrolidone to obtain a uniform active slurry; in the active slurry, the solid component contains 97wt% lithium cobaltate, 2wt% binder PVDF and 1wt% conductive carbon black;

[0060] Apply the above prepared two kinds of slurry to the same side of the aluminum foil (current collector) at the same time, apply the transition layer slurry to the upper side of the current collector to form a transition coating, and apply the active slurry to the transition coating to form Active coating, after dryi...

Embodiment 2

[0067] The difference between Example 2 and Example 1 is that the thickness of the transition coating on one side of the current collector aluminum foil after drying is 10±1um.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com