Preparation method of butenolide compound composite nanocrystals

A crotonic acid lactone and nanocrystal technology is applied in the preparation of organic compounds, the preparation of carboxylic acid esters, organic chemical methods, etc., and can solve the problems of not easy to maintain for a long time, poor stability, restrictions on promotion and use, etc., and achieve stable solutions. Sexual issues, low cost, simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The butyrolactone compound in this example is the fermentation compound butyrolactone I (abbreviation: BTL-1) of Aspergillus terreus H768.

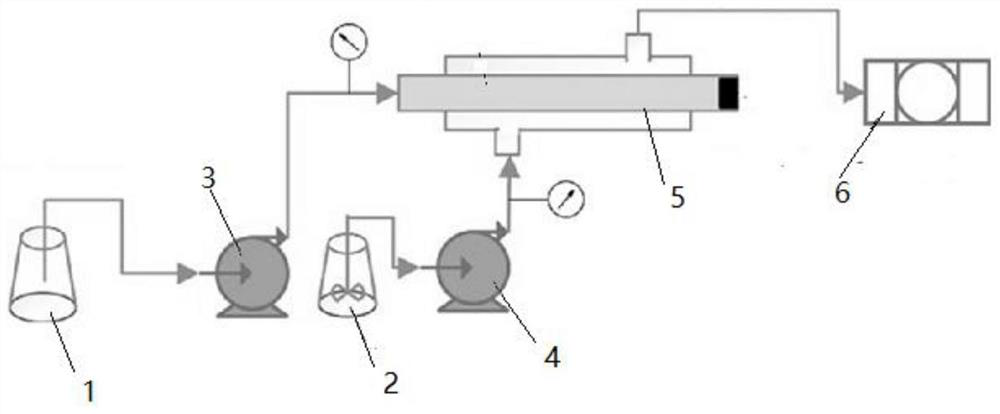

[0029] A method for preparing a butenolide compound nanocrystal, comprising the following steps:

[0030] S1, prepare a BTL-1 ethanol solution with a concentration of 100 mg / mL;

[0031] S2, configure 100mg / mL anhydrous sodium sulfite aqueous solution;

[0032] S3, the BTL-1 ethanol solution 1 in S1 and the anhydrous sodium sulfite aqueous solution 2 in S2 are respectively drawn into the catheter by pump one 3 and pump two 4 and injected into the microporous fiber tube bundle nanocrystallizer 5 respectively, and set to feed into BTL -1 The rotating speed of the pump one of the ethanol solution is 100rpm, and the rotating speed of the pump two which is set to pass into anhydrous sodium sulfite aqueous solution is 300rpm, so that the two are mixed in the microporous fiber tube bundle nano crystallizer 5, and the two interact to form...

Embodiment 2

[0035] The butyrolactone compound in this example is the fermentation compound butyrolactone I (abbreviation: BTL-1) of Aspergillus terreus H768.

[0036] A method for preparing a butenolide compound nanocrystal, comprising the following steps:

[0037] S1, prepare a BTL-1 ethanol solution with a concentration of 100 mg / mL;

[0038] S2, configure 5mg / mL anhydrous sodium sulfite aqueous solution;

[0039] S3, the BTL-1 ethanol solution 1 in S1 and the anhydrous sodium sulfite aqueous solution 2 in S2 are pumped into the catheter through pump one 3 and pump two 4 respectively and then injected into the microporous fiber tube bundle nano crystallizer 5 respectively, and the setting is passed into The rotating speed of the pump one of BTL-1 ethanol solution is 30rpm, and the rotating speed of setting the pump two that feeds anhydrous sodium sulfite aqueous solution is 300rpm, makes the two mix in microporous fiber tube bundle nano crystallizer 5, and the two interact to form cont...

Embodiment 3

[0042] The butyrolactone compound in this example is the fermentation compound butyrolactone I (abbreviation: BTL-1) of Aspergillus terreus H768.

[0043] A method for preparing a butenolide compound nanocrystal, comprising the following steps:

[0044] S1, prepare a BTL-1 ethanol solution with a concentration of 100 mg / mL;

[0045] S2, configure 100mg / mL sodium bisulfite aqueous solution;

[0046] S3, the sodium bisulfite aqueous solution 2 in the BTL-1 ethanol solution 1 in S1 and the sodium bisulfite solution 2 in S2 are pumped into the catheter by pump one 3 and pump two 4 respectively and inject in the microporous fiber tube bundle nano crystallizer 5 respectively, set the pass Enter the rotating speed of the pump one of BTL-1 ethanol solution to be 300rpm, set the rotating speed of the pump two that feeds sodium bisulfite aqueous solution to be 200rpm, make the two mix in microporous fiber tube bundle nano crystallizer 5, the two interact Forming a mixed solution conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com