Semi-aromatic polyamide composition as well as preparation method and application thereof

A semi-aromatic and aliphatic polyamide technology, used in mechanical equipment, combustion engines, internal combustion piston engines, etc., can solve the problems of poor laser penetration uniformity, welding instability, surface laser burns, etc., and achieve excellent Laser weldability, high heat resistance and high laser weld strength, effect of high laser weld strength

Active Publication Date: 2021-03-30

ZHUHAI WANTONG SPECIAL ENG PLASTICS CO LTD

View PDF6 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

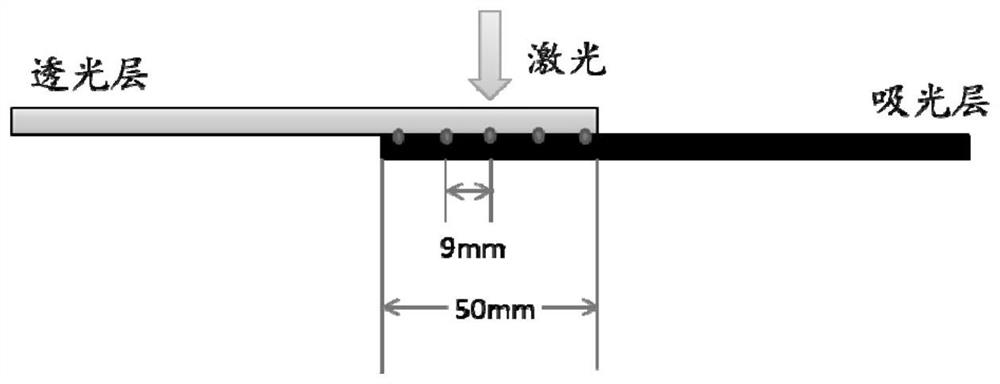

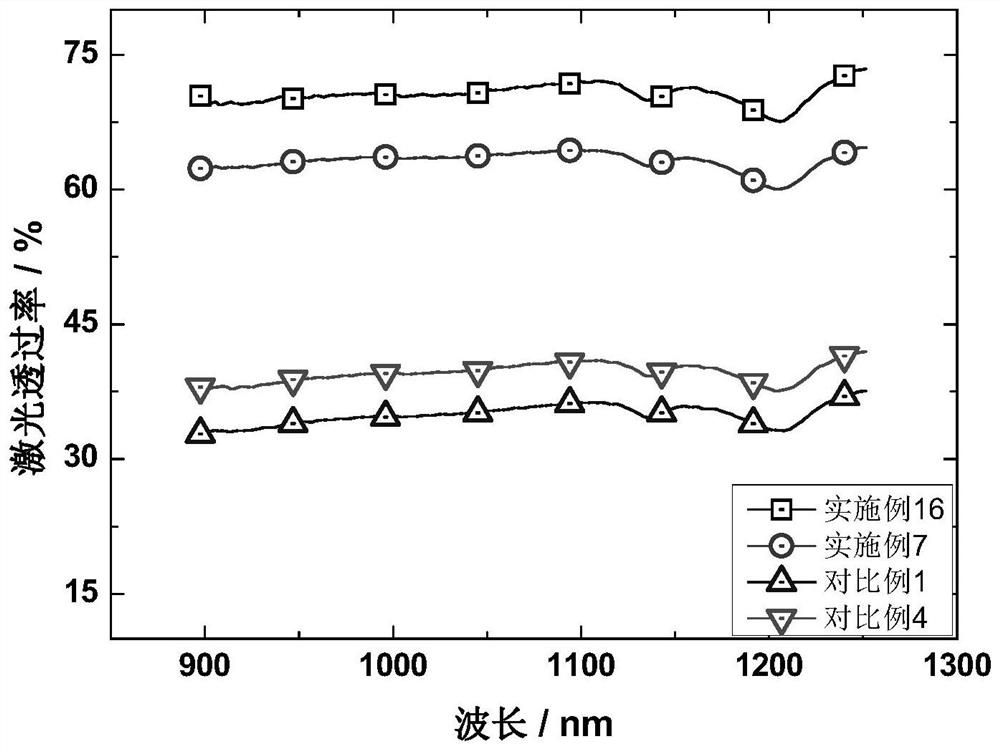

[0006] The present invention provides a semi-aromatic polyamide composition to overcome the welding instability caused by poor laser transmission uniformity and the appearance defects caused by surface laser burns during laser welding.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~8

[0071] The content of each component in the embodiment 1~10 of table 1

[0072]

[0073] The content of each component in table 2 embodiment 11~18

[0074]

[0075]

[0076] The content of each component in the comparative example 1~9 of table 3

[0077]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

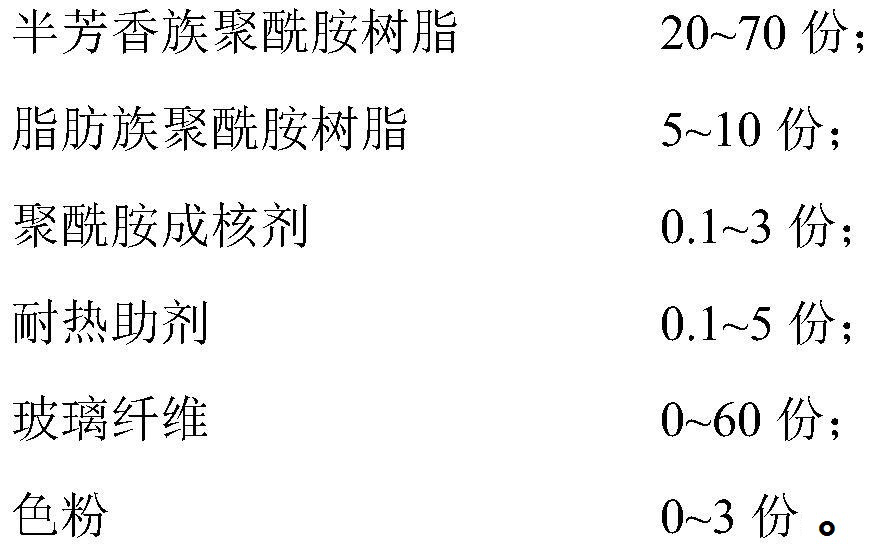

The invention discloses a semi-aromatic polyamide resin composition as well as a preparation method and application thereof. The composition comprises the following components in parts by weight: 20 to 70 parts of semi-aromatic polyamide resin, 1 to 15 parts of aliphatic polyamide resin, 0.1 to 3 parts of a polyamide nucleating agent, 0.1 to 5 parts of a heat-resistant auxiliary agent, 0 to 60 parts of glass fibers, and 0-3 parts of a toner, wherein the aliphatic polyamide is semi-crystalline polyamide of which the melting enthalpy value is not less than 15 J / g. The composition has more excellent laser transmission performance and more excellent laser welding performance; meanwhile, a molded part of the composition can obtain excellent laser transmission uniformity, and the problem of unstable welding in existing laser welding product production can be solved; moreover, by adopting the composition, the problem of poor product appearance caused by surface layer laser burn of the laser-transmitting layer in the welding process can also be remarkably improved at the same time.

Description

technical field [0001] The present invention relates to the technical field of polymer materials, more specifically, to a semi-aromatic polyamide composition and its preparation method and application. Background technique [0002] Polyamide is currently one of the most widely used engineering plastics, widely used in electronic appliances, automobiles, home appliances, sporting goods and other fields. With the increasing structural complexity of automotive parts and some electronic and electrical parts, it is difficult or even impossible to use direct injection molding to make them, so the parts need to be laser welded. Compared with traditional plastic welding processes, such as hot plate welding, hot gas welding, induction welding, spin welding, ultrasonic welding, vibration friction welding, laser welding technology has many advantages: fast welding speed, good welding quality, clean, no vibration. Therefore, this welding process is widely used in plastic precision par...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L77/06C08K7/14C08K5/098C08K5/06C08K5/134C08K13/04

CPCC08L77/06C08L2201/08C08L2205/025C08K7/14C08K5/098C08K5/06C08K5/1345C08K13/04Y02T10/12

Inventor 叶少勇杨硕柴海博龙杰明麦杰鸿姜苏俊曹民

Owner ZHUHAI WANTONG SPECIAL ENG PLASTICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com