A processing method based on anisotropic homogenization of multiple isotropic materials

An anisotropic and isotropic technology, applied to the analysis of materials, material inspection products, material thermal conductivity, etc., can solve problems such as ignoring anisotropy and deviation of experimental values, so as to achieve easy acceptance and mastery, improve efficiency, and simplify Workflow Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

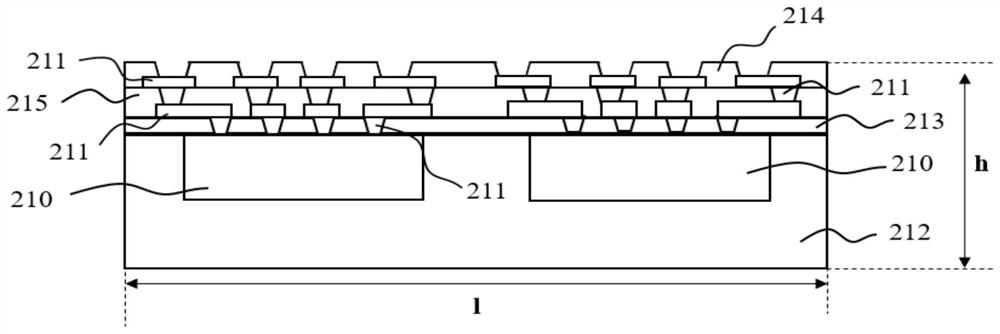

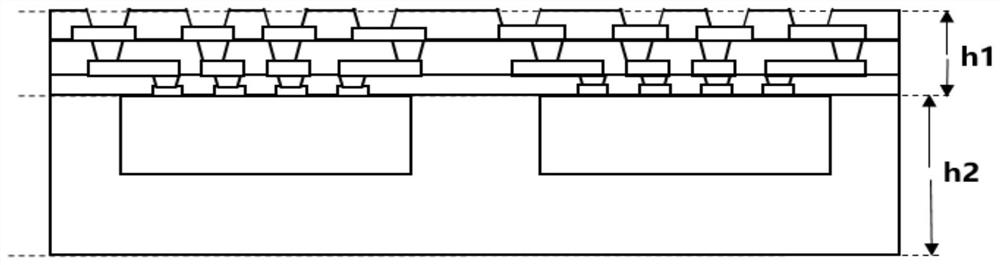

[0058] Please refer to figure 1 , figure 2 , Figure 4 , Figure 6 As shown, the polyisotropic material structure simplifies the calculation of the elastic modulus and Poisson's ratio parameters for the bilayer model:

[0059] Such as figure 2 Shown is a simplified double-layer model of multi-isotropic material structure, which exists in most electronic devices and involves the packaging process of electronic devices. A whole module is simplified into a two-layer model, which simplifies the measurement process and improves the measurement efficiency. accuracy. This double-layer structure includes a redistribution layer 211 (Re-distributed Layer RDL), a passivation layer 214 , and a chip film 213 . The elastic parameters of the redistribution layer 211 are as follows:

[0060] Elastic modulus E=110GPa, Poisson's ratio μ=0.34, coefficient of thermal expansion CTE=17ppm / ℃

[0061] The elastic parameters of the passivation layer 214 are as follows:

[0062] Elastic modul...

Embodiment 2

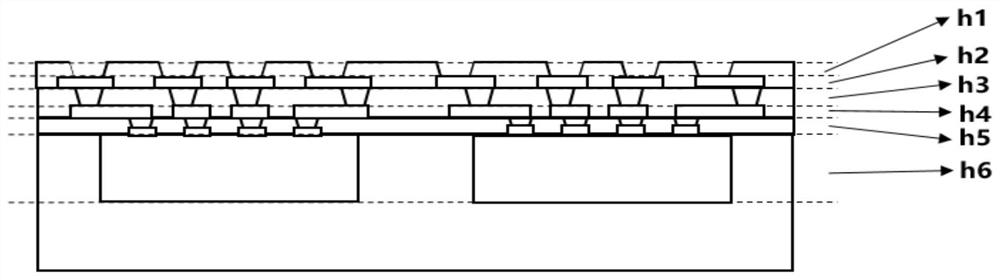

[0098] Please refer to image 3 , Figure 5 , Figure 7 As shown, the polyisotropic material structure simplifies the calculation of the elastic modulus and Poisson's ratio parameters of the six-layer model:

[0099] Such as image 3 Shown is a simplified six-layer model of multi-isotropic material structure. This structure exists in most electronic devices and involves the packaging process of electronic devices. A whole module is simplified into a six-layer model, which simplifies the measurement process and improves the measurement efficiency. accuracy. This six-layer structure includes a redistribution layer 211 (RDL), a passivation layer 214 , a chip film 213 , a chip 210 , and a dielectric layer 215 . The elastic parameters of the redistribution layer 211 are as follows:

[0100] Elastic modulus E=110GPa, Poisson's ratio μ=0.34, coefficient of thermal expansion CTE=17ppm / ℃

[0101] The elastic parameters of the passivation layer 214 are as follows:

[0102] Elasti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com