A special vehicle tank inclination detection and inclination control method and application

A technology for tanks and vehicles, which is applied in the field of tank inclination detection and tilt control of special vehicles, can solve problems such as excessive tank turnover, limit failure of the main controller, and evolution of production accidents, so as to ensure safety and reliability. , avoid the risk of derailment, remove the effect of cable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Example 1: Special vehicle tank tilt angle detection and tilt control technology

[0055] 1.1 Design of inclination detection and control scheme

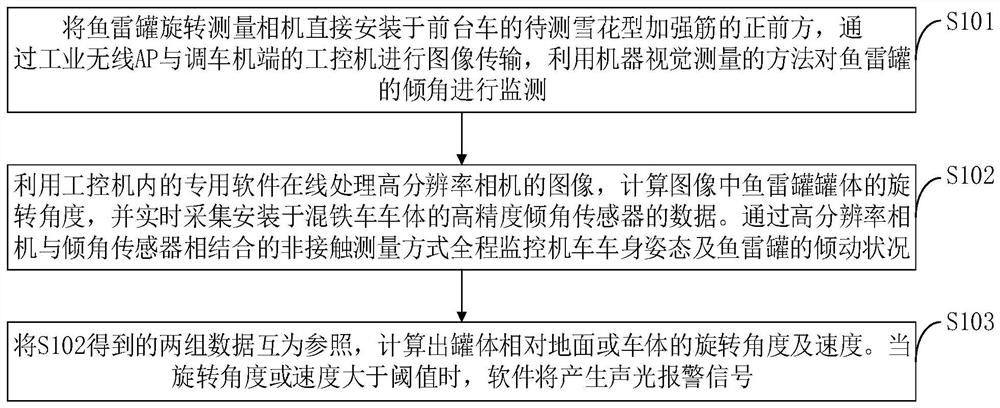

[0056] The inclination angle of the torpedo tank is monitored by using the method of machine vision measurement, and the body posture of the locomotive and the tilting condition of the torpedo tank are monitored throughout the whole process through the non-contact measurement method combined with the high-resolution camera and the inclination sensor, so as to avoid the torpedo tank caused by being too close to the tank. Monitoring equipment fails or becomes unstable at high temperatures, causing a risk of derailment for the locomotive.

[0057] The system is designed to install the torpedo rotation measurement camera directly in front of the snowflake-shaped reinforcing rib to be tested on the front trolley, and transmit the image through the industrial wireless AP and the industrial computer at the shunting machine side. On...

Embodiment 2

[0069] Embodiment 2: Image recognition tilt angle calculation method test

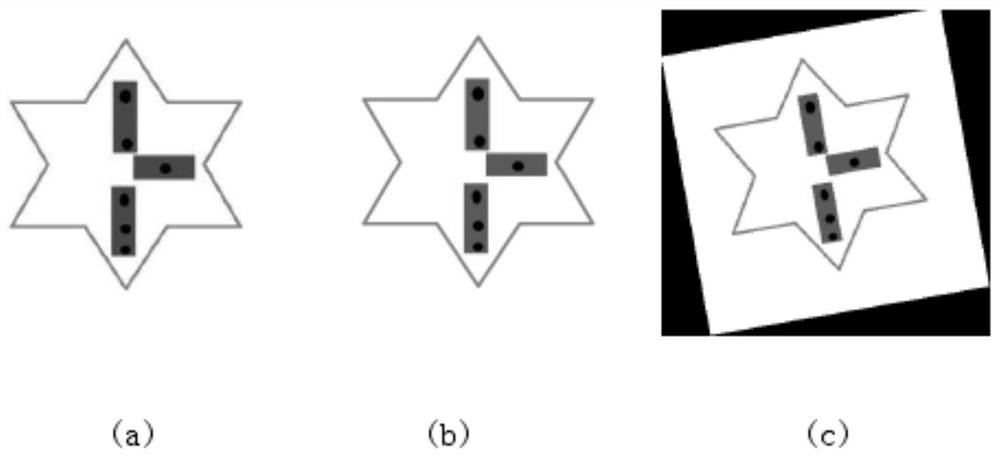

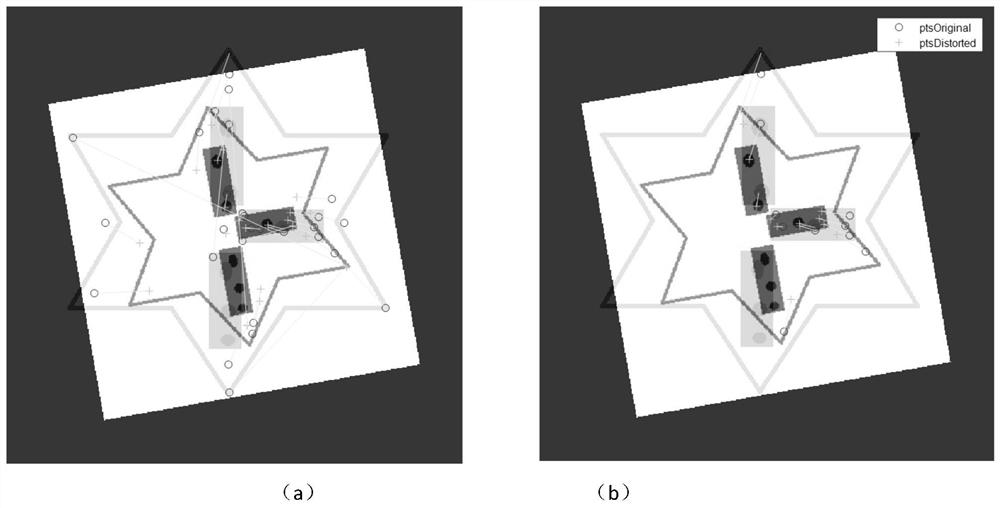

[0070] test images such as figure 2 shown, figure 2 (a) is the original image; figure 2 (b) is a grayscale image; figure 2 (c) is an image rotated by 10°. Feature point extraction and matching such as image 3 shown, image 3 (a) is the feature point extraction, image 3 (b) is the feature point matching. Test results such as Figure 4 shown, Figure 4 (a) is the test image 2, Figure 4 (b) is the test image 3.

[0071] The present invention simulates and tests the measurement accuracy of the algorithm through multiple sets of experimental images, figure 2 and image 3 For the measurement process in a set of test cases, the software first turns the image into black and white, then extracts the feature points in the initial image and the rotated image respectively, matches the feature points, and finally converts the rotation between the two images through the matching relationship. an...

Embodiment 3

[0075] Example 3: Image Recognition Inclination Calculation Simulation Experiment Test

[0076] 3.1 Test environment

[0077] The angle of rotation is measured using eg Figure 5 The method shown, in which the precision rotating table table is used as the measured object.

[0078] The precision rotary platform is driven by a 42-step motor, and the rotation angle is precisely controlled by an external stepper motor driver. The parameters of the precision rotary table and drive are shown in Table 2.

[0079] Table 2 Test equipment performance parameter table

[0080]

[0081] 3.2 Test experiment of inclination angle measurement accuracy

[0082] (Indicator requirements: inclination detection accuracy 0.5°, inclination control accuracy 1°)

[0083] The measurement accuracy of the inclination angle depends on the measurement mean value and the error distribution of the equipment. Since the tilting range of the torpedo tanker is limited within the range of ±120°, in the tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com