Rapid transportation device taking pipe as track

A technology of transportation and pipelines, which is applied in the field of vehicles, can solve problems such as derailment risks that cannot be solved, and achieve the effect of avoiding derailment risks and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0076] Experimental example 1. Passive open one-way airflow window simulation experiment:

[0077] Experimental materials: 500 X 375 X 375mm electric remote control toy car, remote control, 3mm thick plexiglass plate, rubber gasket, 400 X 400mm plexiglass tube.

[0078] Preparation of the experimental device: On the side wall of the plexiglass tube, a square hole of 90 X 90 mm is horizontally opened at an interval of 100 mm. Take a plexiglass plate, cut it into a 100 X 100mm square plate, and paste a 95 X 95mm square rubber gasket on one side. The rubber gasket is inwardly fixed on the outside of the opening of the plexiglass tube in a suspended manner. Straight-line connected plexiglass tubes are 20 meters long. Put the electric RC toy car into one end of the pipe.

[0079] Experimental methods and results: start the electric remote control toy car by remote control, accelerate, it can be seen that the electric remote control toy car is running quickly in the pipeline, and...

experiment example 2

[0080] Experimental example 2. Running experiment in the running structure pipeline:

[0081] Experimental materials: 1.5mm thick stainless steel plate, 30 X 30mm angle iron, rubber pad, permanent magnet block, bearing, 0-100KPa vacuum pressure gauge, 8.5KW plant protection machine, 11V 8000mA DUPU lithium battery, 180mm diameter rubber wheel, electric Adjustment, remote control, bearing.

[0082] Preparation of experimental device:

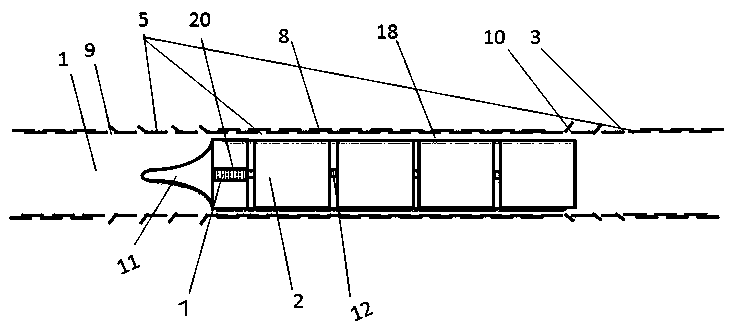

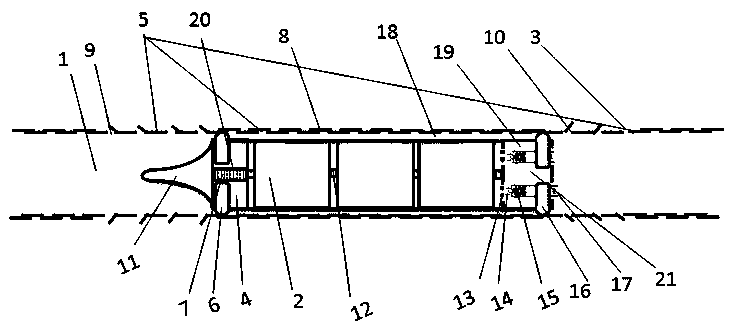

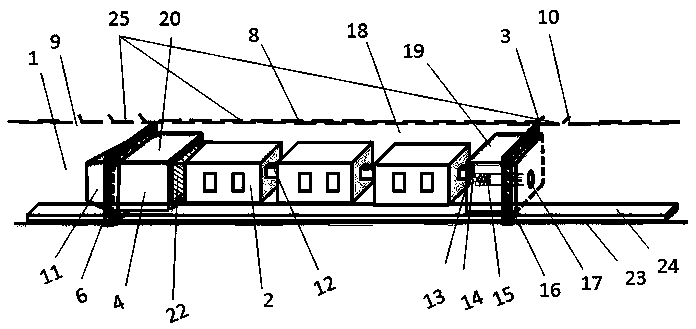

[0083] 1. Preparation of pipeline structure: use 1.5mm thick stainless steel plate to make such as figure 2 150 stainless steel pipes with a length of 1.5 meters and a diameter of 600 X 600mm. On the pre-planarized test site, connect each section of stainless steel pipes and fix them with screws to form a 200-meter-long test pipe structure.

[0084] 2. Preparation of the running structure in the pipeline with drive: first make a 590 X 590 X 590mm square bracket with angle iron, and use a 1.5mm thick stainless steel plate to install the bottom...

experiment example 3

[0087] Experimental example 3. Pipeline plugging operation decompression experiment (1):

[0088] Experimental materials: 1.5mm thick stainless steel plate, 30 X 30mm angle iron, 3mm diameter steel wire rope, rubber pad, hinge, permanent magnet block, 15KW three-phase motor, vertical winch, bearing, 0-100KPa vacuum pressure gauge.

[0089] Preparation of experimental device:

[0090] 1. Preparation of pipeline structure: use 1.5mm thick stainless steel plate to make such as figure 2 There are 150 stainless steel pipes with a length of 1.5 meters and a diameter of 600 X 600mm, and 9 one-way airflow windows of 100 X 150mm on each side. The stainless steel plate is used as the window cover, the rubber pad is used as the sealing strip, and the permanent magnet block is used as the closer. On the pre-planarized test site, connect each section of stainless steel pipes and fix them with screws to form a 200-meter-long test pipe structure.

[0091] 2. Preparation of the pulling ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com