A dual water-cooled melting nozzle for metal 3D printing

A 3D printing, double water cooling technology, applied in additive manufacturing, additive processing, etc., can solve the problems of harsh environmental conditions, high technical difficulty, immersion and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

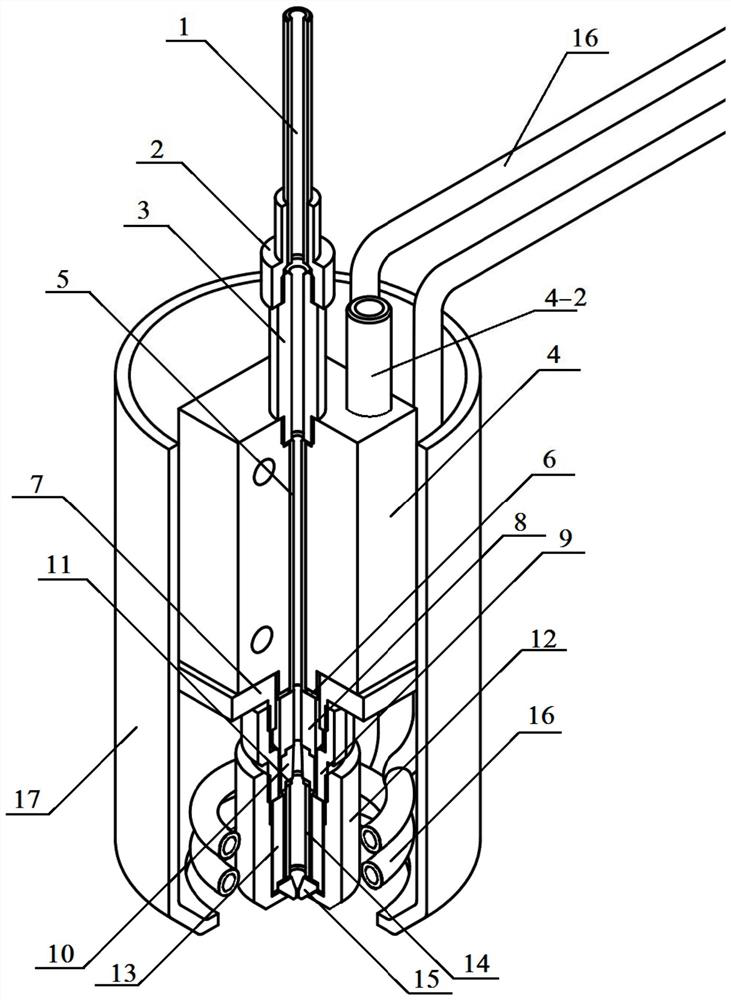

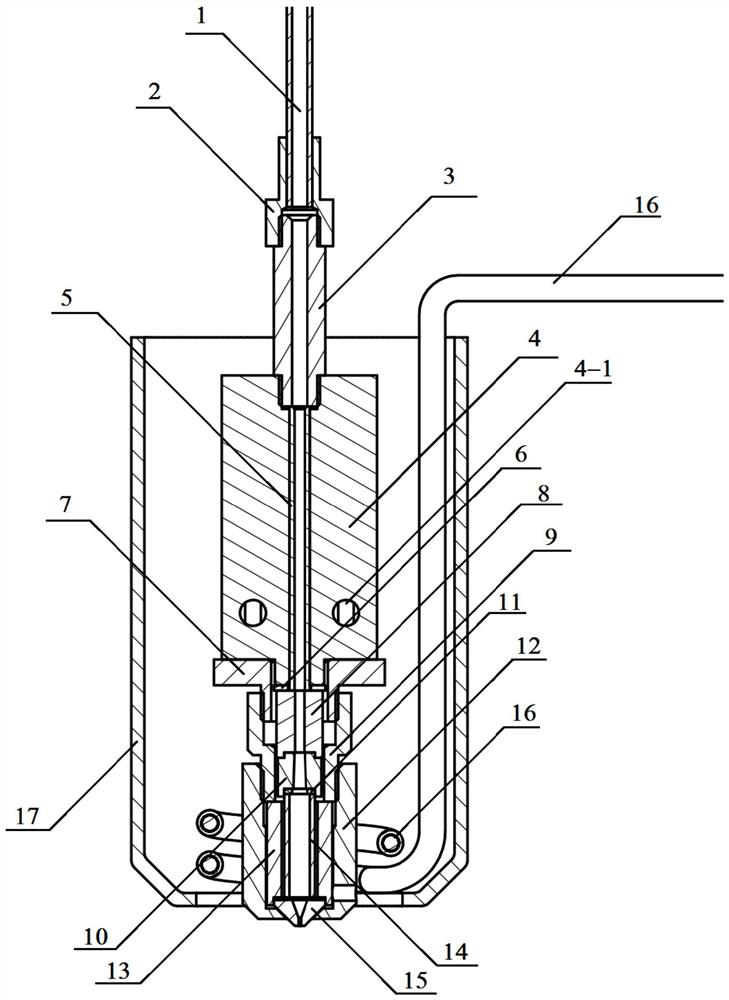

[0034] like figure 1 , figure 2 As shown, this embodiment provides a double water-cooled melting nozzle for metal 3D printing, which is a metal 3D printing melting nozzle that uses electromagnetic induction heating as a heat source to heat the metal wire into a molten state and then extrude it. Melt extrusion nozzle. The carbon steel heating tube in the molten extrusion nozzle is heated by electromagnetic induction to form a high temperature chamber. The metal wire is sent from the wire guide tube into the high temperature chamber and softened into liquid or molten metal by heating. The method extrudes the molten metal from the small hole under the nozzle, and performs the process of stacking and forming. The physical process is similar to the 3D printing principle of organic materials.

[0035] Specifically, it includes: wire feed tube 1, wire feed tube joint 2, hot and cold transition tube 3, water-cooled heat exchanger 4, inner diameter tube 5, copper pad 6, fastening sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com