A track elastic pressing device, track robot and method

An orbital robot, elastic pressing technology, applied in the direction of manipulators, manufacturing tools, etc., can solve problems such as difficulty in ensuring the accuracy of parking positions, high precision requirements for rack installation, and inability to brake in time, so as to achieve rational utilization and improve patrolling. Detecting distance and solving the effect of poor climbing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

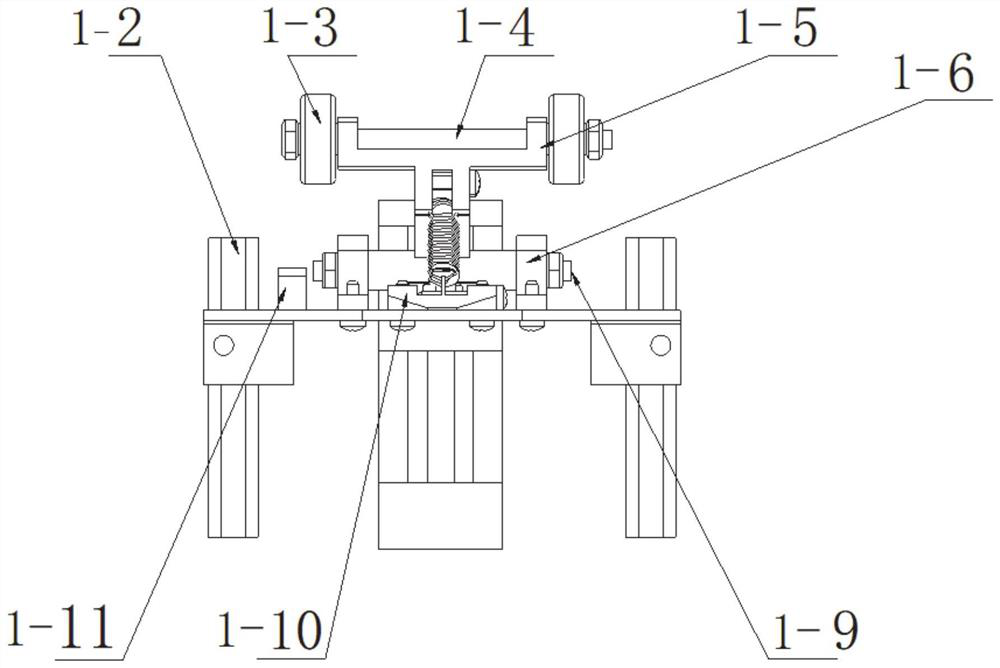

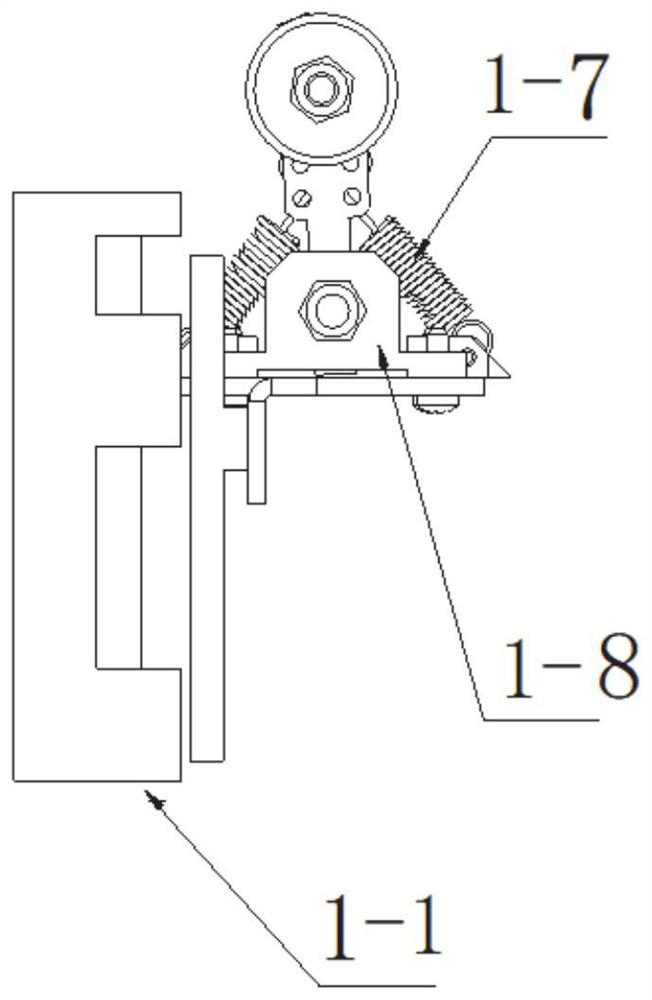

[0034] According to an embodiment of the present invention, an embodiment of a track elastic pressing device is provided, referring to Figure 1-2 , including: a base, a bearing seat 1-6 fixed on the base, and a swing arm support 1-5 connected to the bearing seat 1-6 through a bearing 1-8; On the side, elastic tensioning parts are arranged respectively, and one end of the elastic tensioning parts is connected with the swing arm bracket 1-5, and the other end is fixed to the base through a connecting piece; track pressing parts are arranged on the swing arm bracket 1-5.

[0035] Specifically, the track pressing part is a pressing wheel 1-3, and a card slot is provided at the top of the swing arm support 1-5, and a swing frame rotating shaft 1-4 is arranged in the card slot, and the two ends of the swing frame rotating shaft 1-4 are respectively Connect the pressing wheels 1-3 by nuts. Of course, the track pressing member can also be implemented with other structures, such as a...

Embodiment 2

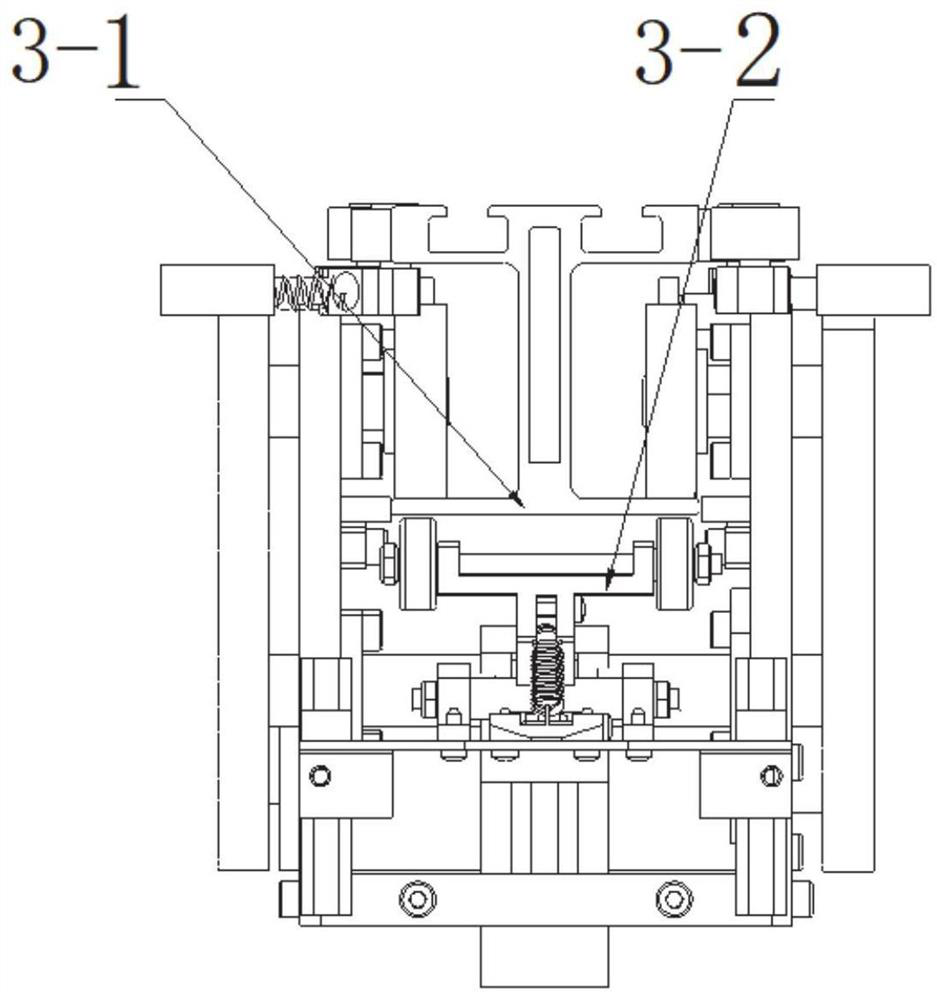

[0042] According to an embodiment of the present invention, an embodiment of an orbital robot 7-1 is provided, referring to image 3 with Figure 4 , including: the track elastic pressing device 3-2 described in Embodiment 1; in addition, a signal reading device is provided at a set position on the track robot 7-1, and a position is set at the beginning end and the end end of the climbing track Tag; in this embodiment, the position tag is an RFID induction tag 4-2, and the signal reading device is an RFID card reader 4-4.

[0043] When the robot moves to the position of the RFID tag (i.e. the RFID sensor tag 7-2 in front of the curved rail) at the climbing point, the RFID card reader 4-4 on the robot receives the RFID tag signal, and the robot controls the electric linear guide rail 1-1 to drive the swing. The arm-type track elastic pressing device moves upward, and the laser ranging sensor installed on the swing-arm elastic pressing mechanism measures the relative distance b...

Embodiment 3

[0053] According to an embodiment of the present invention, an embodiment of a method for an orbital robot 7-1 to climb a track is provided, referring to Figure 7 with Figure 8 ,include:

[0054] When the robot runs to the position of the climbing track and reads the information of the position label at the starting end of the climbing track, the robot control device controls the elastic pressing device of the track to move closer to the track, and measures the distance between the set position of the elastic pressing device of the track and the track in real time. distance, until the distance reaches the set requirements, so as to maintain an optimal pressing force between the track elastic pressing device and the track;

[0055] When the robot reads the information of the position label at the end of the climbing track, the robot control device controls the track elastic pressing device to move away from the track and return to the initial position.

[0056] When the rob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com