Non-burst ceramic preparation device and method

A ceramic preparation and outer surface technology, applied in ceramic forming machines, ceramic forming workshops, manufacturing tools, etc., can solve the problems of unstable and shaking of ceramic products on the conveyor belt, reduce the difficulty of clamping and cleaning, and be safe and convenient to use , Ease of clamping and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

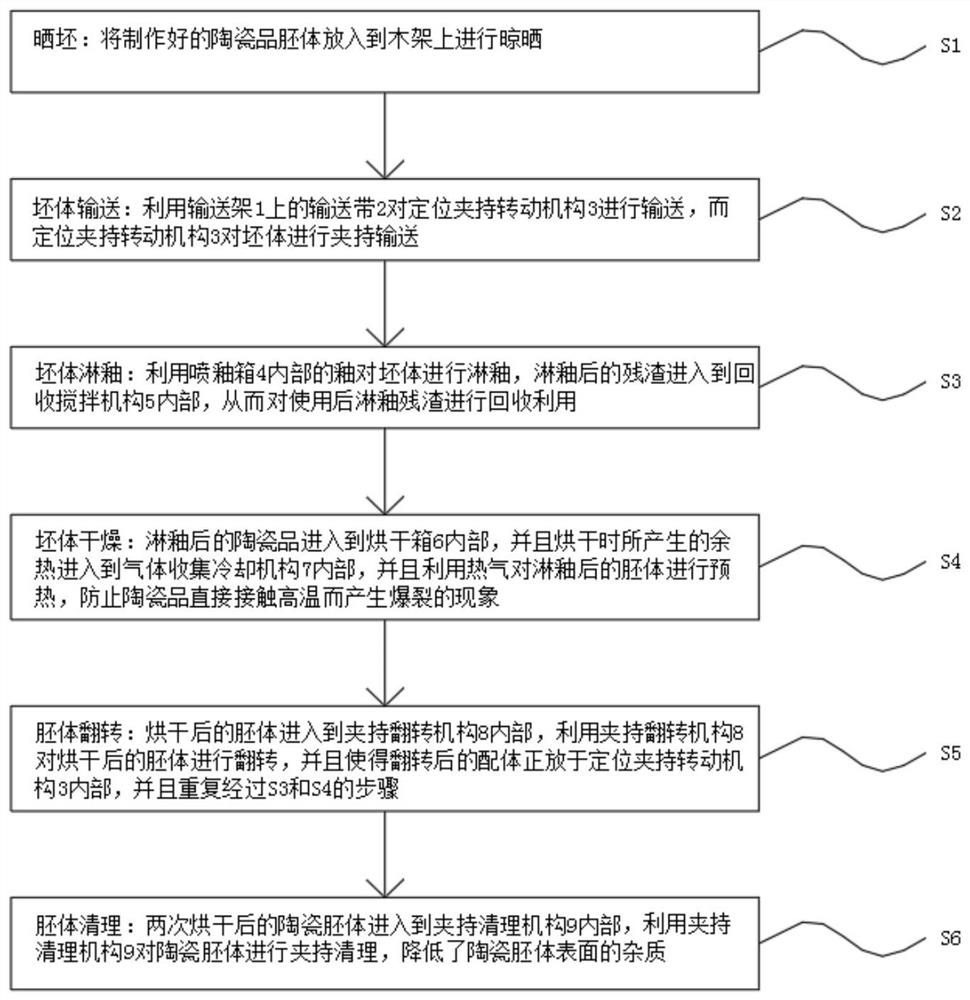

[0049] Such as figure 1 As shown, the present invention provides a kind of technical scheme, a kind of non-explosive ceramic preparation method, comprises the following steps;

[0050] S1: Drying: put the prepared ceramic body on a wooden frame for drying;

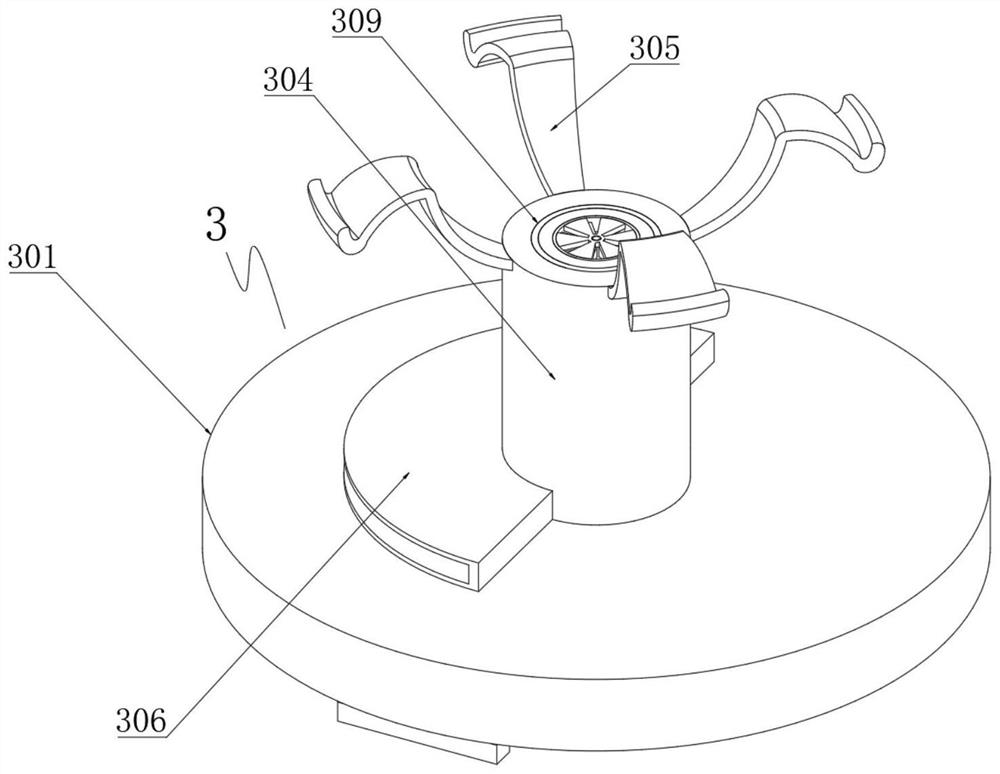

[0051] S2: Green body conveying: use the conveyor belt 2 on the conveyor frame 1 to transport the positioning clamping and rotating mechanism 3, and the positioning, clamping and rotating mechanism 3 clamps and transports the green body;

[0052] S3: Glaze the body: use the glaze inside the glaze spray box 4 to glaze the body, and the residue after glaze enters the recovery stirring mechanism 5, so as to recycle the glaze residue after use;

[0053] S4: Green body drying: glazed ceramics enter the interior of the drying box 6, and the waste heat generated during drying enters the interior of the gas collection and cooling mechanism 7, and the hot air is used to preheat the glazed green body , to prevent ceramic products ...

Embodiment 2

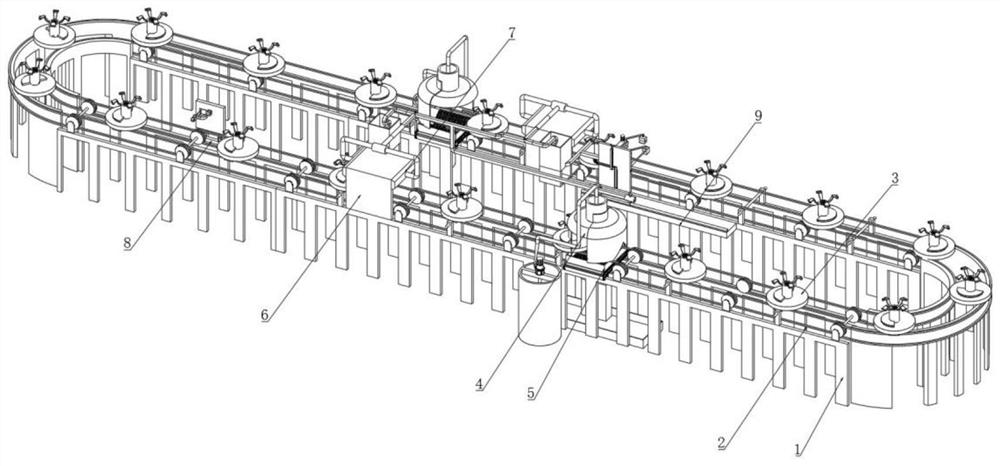

[0057] Such as Figure 2-17 As shown, the present invention provides a technical solution, a non-explosive ceramic preparation device, the middle part of the inner wall of the support frame 1 is rotatably connected to the conveying line 2, and the back side of the support frame 1 is connected to a clamping and cleaning mechanism 9, and the clamping and cleaning mechanism 9 includes electric slide rail 901, slider 902, vertical electric telescopic rod 903, fixed plate 904, slave commutator 905, positive and negative motor 906, two-way threaded rod 907, T-shaped block 908, horizontal electric telescopic rod 909, fixed block 910, connector 911, driven block 912, pulley 913, connecting belt 914, T-shaped wheel 915, toothed rod 916, slide plate 917, three-phase motor 918, sponge 919, limit cylinder 920 and limit bar 921;

[0058] The back side of the support frame 1 is connected with an electric slide rail 901, and the middle part of the top of the electric slide rail 901 is slidab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com