Nano-diamond polishing solution for SiC substrate processing and preparation method thereof

A technology of nano-diamond and polishing fluid, which is applied in the fields of polishing compositions containing abrasives, semiconductor/solid-state device manufacturing, electrical components, etc., and can solve problems such as low polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A nano-diamond polishing solution for processing SiC substrates, consisting of: 500g of water, 15g of diamond micropowder, 3g of fatty alcohol polyoxyethylene ether (dispersant), 25g of hydroxyethyl cellulose (suspending agent), and modified sodium polyacrylate (suspension agent) 25g, ethylene glycol 75g (lubricant), silicone defoamer 0.5g.

[0033] The preparation method of above-mentioned polishing fluid, comprises the steps:

[0034] S1. Get 100g of water and 3g of fatty alcohol polyoxyethylene ether to form a dispersant solution after uniform mixing;

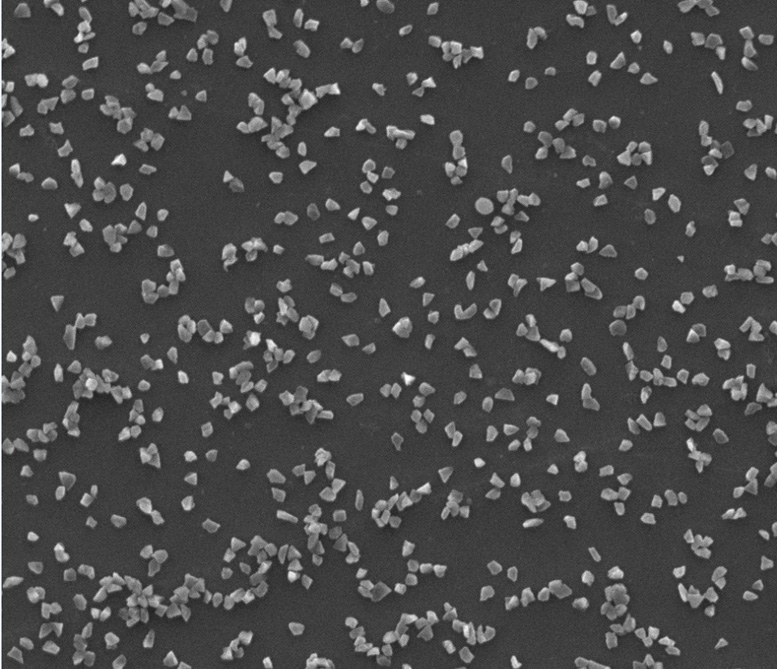

[0035] S2. Under stirring conditions, slowly add 15g of 600nm diamond micropowder with wear-resistant abrasive particles / round abrasive particle number ratio of 1 to the dispersant solution, and use 500W ultrasonic wave to disperse for 90min until the diamond micropowder is completely dispersed and uniform, forming diamond micropowder Dispersions;

[0036] S3. Take 400g of water, add 25g each of hydroxyethyl cellulo...

Embodiment 2

[0039] A preparation method of nano-diamond polishing liquid for SiC substrate processing, comprising the steps of:

[0040] S1. Take 100g of water and mix evenly with 3g of sodium citrate to form a dispersant solution.

[0041] S2. Under stirring conditions, slowly add 15g of 600nm diamond micropowder with wear-resistant abrasive grains / circular abrasive grain number ratio of 3 to the dispersant solution, and disperse with 500W ultrasonic wave for 90min to form diamond micropowder dispersion liquid.

[0042] S3. Take 400g of water, add 25g each of hydroxyethyl cellulose and modified sodium polyacrylate, fully stir to dissolve evenly, and form a suspending agent solution.

[0043] S4. Mix the diamond micropowder dispersion and suspending agent solution evenly, add 75g of ethylene glycol and 0.5g of silicone defoamer in sequence, and stir evenly.

Embodiment 3

[0045] A preparation method of nano-diamond polishing liquid for SiC substrate processing, comprising the steps of:

[0046] S1. Take 100g of water and 3g of fatty alcohol polyoxyethylene ether and mix them uniformly to form a dispersant solution.

[0047] S2. Under stirring conditions, slowly add 15g of 600nm diamond micropowder with wear-resistant abrasive grains / circular abrasive grain number ratio of 6 to the dispersant solution, and disperse with 500W ultrasonic wave for 90min to form diamond micropowder dispersion liquid.

[0048] S3. Take 400g of water, add 25g each of hydroxyethyl cellulose and modified sodium polyacrylate, fully stir to dissolve evenly, and form a suspending agent solution.

[0049] S4. Mix the diamond micropowder dispersion and suspending agent solution evenly, add 75g of ethylene glycol and 0.5g of silicone defoamer in sequence, and stir evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com