Treatment method of defatted rice bran

A technology of defatted rice bran and a processing method, which is applied in the field of food processing, can solve the problems of reducing nutritional value, waste, and insufficient utilization of effective resources, and achieves the effects of increasing economic benefits and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

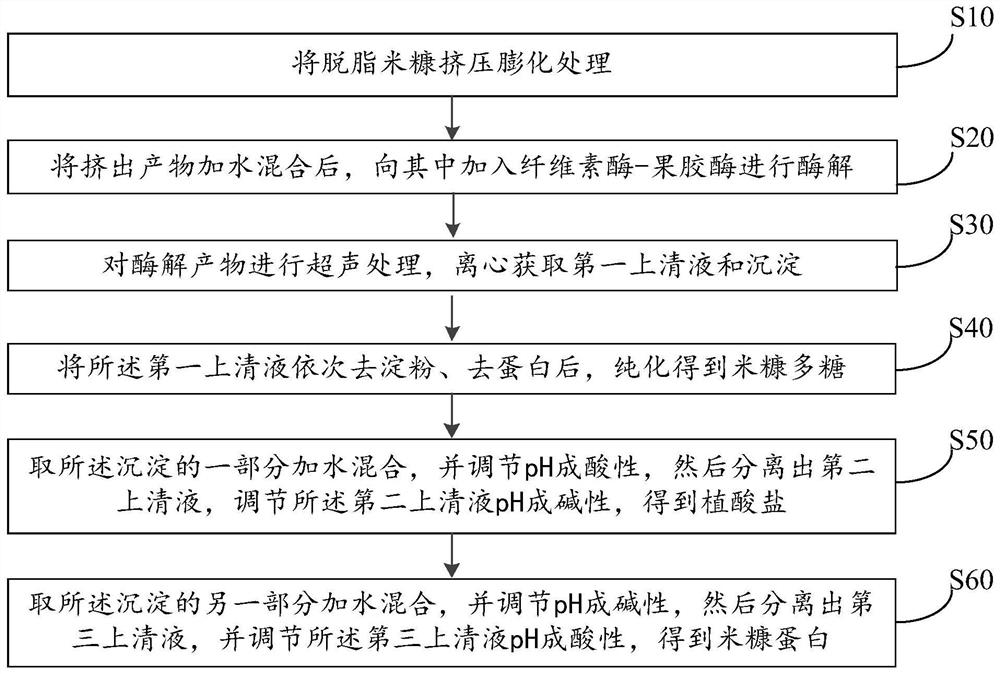

Method used

Image

Examples

Embodiment 1

[0066] (1) Extruding and expanding the defatted rice bran. When extruding and expanding, set the water content of the material to 20%, and add corresponding proportion of distilled water accordingly. Then set the extrusion temperature of the extruder to 120° C., and the screw speed to 150 r / min. After the extrusion is finished, the extrudate is crushed and ground into powder, and then sealed and bagged for later use.

[0067] (2) Add distilled water 25 times the weight of the extruded product to the extruded product, stir and mix evenly, and then adjust the pH to 4.0. Add compound enzyme enzymolysis 40min therein, wherein, the compound enzyme addition amount is 1%, compound enzyme is mixed by weight ratio 1:1 by cellulase (enzyme activity 15000U / g) and pectinase (enzyme activity 30000U / g) made.

[0068] (3) The enzymatic hydrolysis product was ultrasonically treated at 80° C. and 400 W power for 60 minutes, and then centrifuged at 4000 r / min for 20 minutes to obtain the fir...

Embodiment 2

[0073] (1) Extruding and expanding the defatted rice bran. When extruding and expanding, set the water content of the material to 20%, and add corresponding proportion of distilled water accordingly. Then set the extrusion temperature of the extruder to 120° C., and the screw speed to 150 r / min. After the extrusion is finished, the extrudate is crushed and ground into powder, and then sealed and bagged for later use.

[0074] (2) Add distilled water 10 times the weight of the extruded product to the extruded product, stir and mix evenly, and then adjust the pH to 4.0. Add compound enzyme enzymolysis 40min therein, wherein, the compound enzyme addition amount is 1%, compound enzyme is mixed by weight ratio 1:1 by cellulase (enzyme activity 15000U / g) and pectinase (enzyme activity 30000U / g) made.

[0075] (3) The enzymatic hydrolysis product was ultrasonically treated at 80° C. and 300 W power for 60 minutes, and then centrifuged at 4000 r / min for 20 minutes to obtain the fir...

Embodiment 3

[0080] (1) Extruding and expanding the defatted rice bran. When extruding and expanding, set the water content of the material to 20%, and add corresponding proportion of distilled water accordingly. Then set the extrusion temperature of the extruder to 115° C., and the screw speed to 120 r / min. After the extrusion is finished, the extrudate is crushed and ground into powder, and then sealed and bagged for later use.

[0081] (2) Add distilled water 15 times the weight of the extruded product to the extruded product, stir and mix evenly, and then adjust the pH to 4.0. Add compound enzyme enzymolysis 40min wherein, wherein, compound enzyme addition is 1%, compound enzyme is mixed by weight ratio 1:1.1 by cellulase (enzyme activity 15000U / g) and pectinase (enzyme activity 30000U / g) made.

[0082] (3) The enzymatic hydrolysis product was ultrasonically treated at 60° C. and 300 W power for 60 minutes, and then centrifuged at 4000 r / min for 20 minutes to obtain the first supern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com