Electrolysis-electrodeposition machining device and method for repairing SLM formed part

A processing device and molding technology, applied in the field of electrolytic-electrodeposition combined processing devices, can solve problems such as poor surface quality of the molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

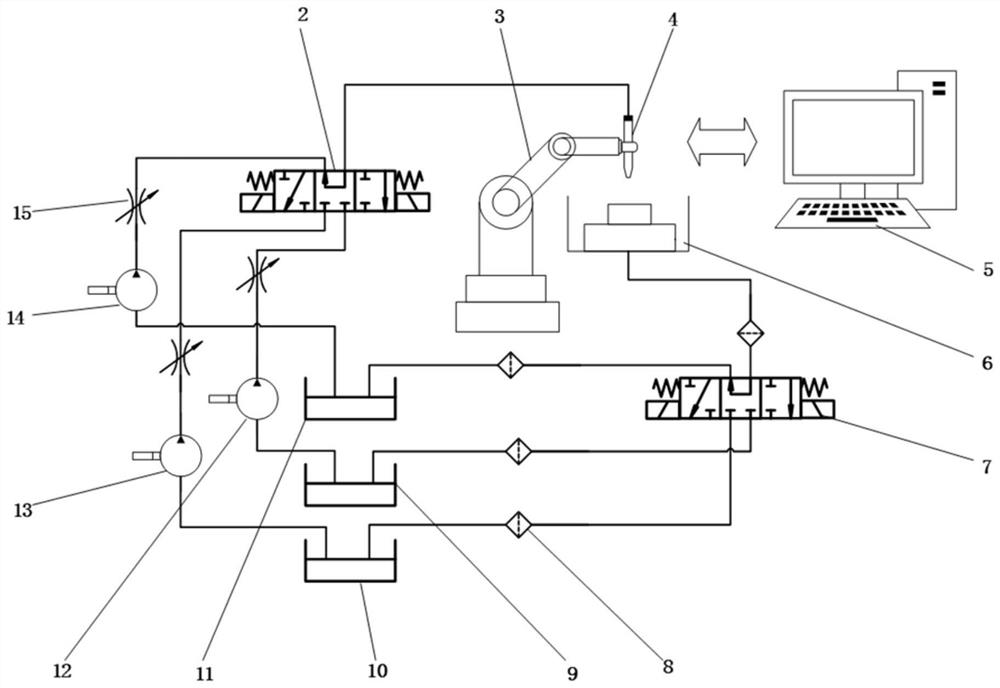

[0048] Such as figure 1 As shown, an electrolysis-electrodeposition combined processing device for repairing SLM molded parts includes a first electromagnetic reversing control valve 2, a small six-axis robot arm 3, a computer control system 5, a workbench 6, and a second electromagnetic reversing control valve. Valve 7; the entire machining process and numerically controlled mechanical devices are controlled by a computer control system 6, and the compilation of this system should be based on the evaluation of surface defects of SLM molded parts by technical experts, comprehensive empirical parameters of jet electrolysis and jet electrodeposition, and finite element analysis results . The system should include optimized process parameters such as scanning times and scanning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com