Collection equipment and collection process of aerosol powder equipment

A technology for collecting equipment and powder, applied in metal processing equipment, process efficiency improvement, sieve and other directions, can solve the problems of powder escape, the inability to effectively guarantee the purity and quality, and the low efficiency of mechanical pulverization. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

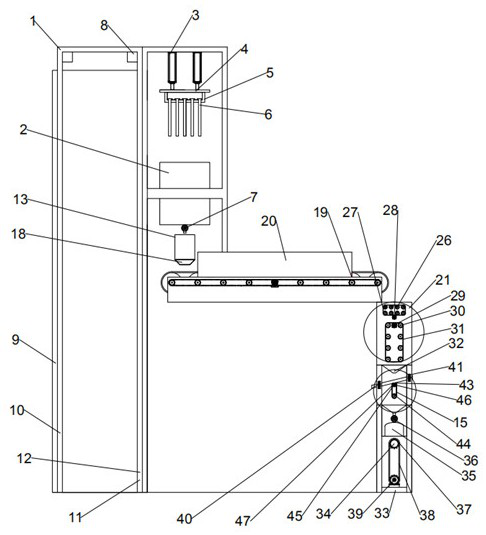

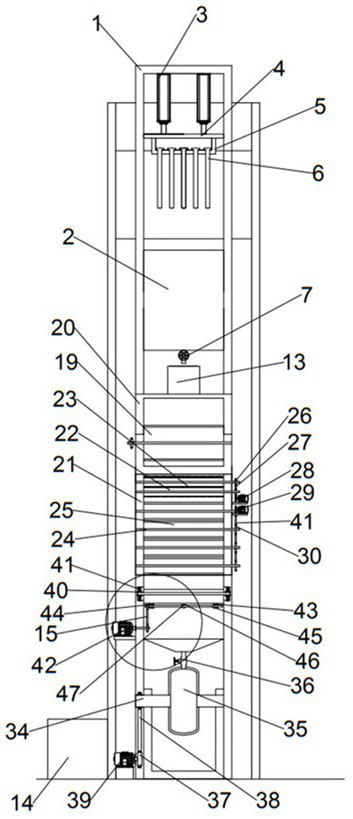

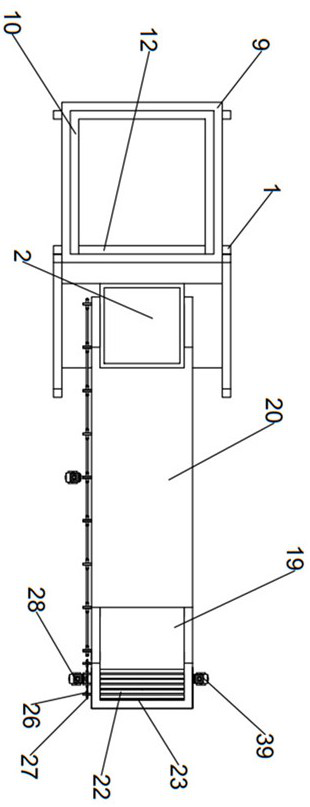

[0040]EXAMPLER: By falling metal waste into the lifting limit box 9 inner rising box 10, the two pairs of lifting hoist 8 operates, driving the lifting box 10 on the lifting limit box 9, raising the lifting box 10 When the lifting limit box 9 is reached, there is no limit to the lifting limit box 9 through the discharge plate 12 on the lifting box 10, so that the discharge plate 12 on the lifting box 10 rotates along the discharge shaft 11, so that The lifting box 10 is leaked, so that the metal waste in the lifting box 10 slides into the electric furnace 2 through the discharge plate 12, by elongation of the two pairs of electric heating hydraulic push rods 3, pushing the two pairs of electric heating hydraulic push rod 3 push the end The electric heating plate 4 on the upper electric heating plate 4 is inserted into the electric furnace 2 in the electric furnace 2, and the metal in the electric furnace 2 is hot melt in the electric furnace 2 by a plurality of electric heating stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com