A kind of al-re-nb ternary alloy containing both high melting point and low boiling point elements and preparation method thereof

A technology of ternary alloys and high melting point metals, which is applied in the field of Al-Re-Nb ternary alloys and its preparation, can solve problems such as unseen and melting loss of Al elements, and achieve reduced volatilization, reduced melting loss, and reduced samples Quantity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

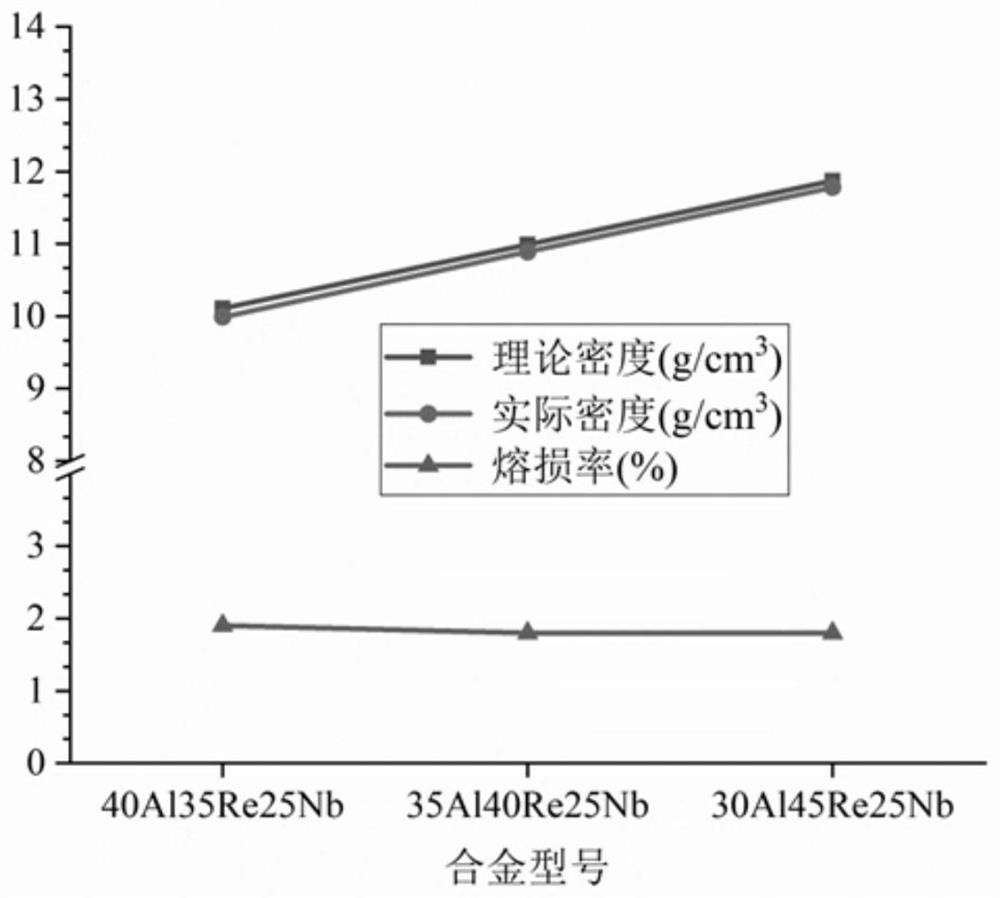

[0020] The Al-Re-Nb ternary alloy containing high melting point and low boiling point elements prepared by the present invention has the following components in terms of mass percentage: Al 40%, Re 35%, and the balance is Nb.

[0021] The preparation method of described Al-Re-Nb ternary alloy, its steps are as follows:

[0022] Material selection: select Al, Re, Nb three pure metal raw materials with a purity of 99.99%; Al and Re are particles with a particle size of about 2mm, and Nb is a thin sheet with a thickness of about 0.5mm.

[0023] Raw material processing and batching: put the above metal raw materials into acetone solution for ultrasonic cleaning for 15 minutes, take them out and put them in alcohol for ultrasonic cleaning for 15 minutes, and use a hair dryer to dry them immediately after cleaning. The dried raw materials are weighed according to the above mass percentages on an electronic balance with an accuracy of 0.0001.

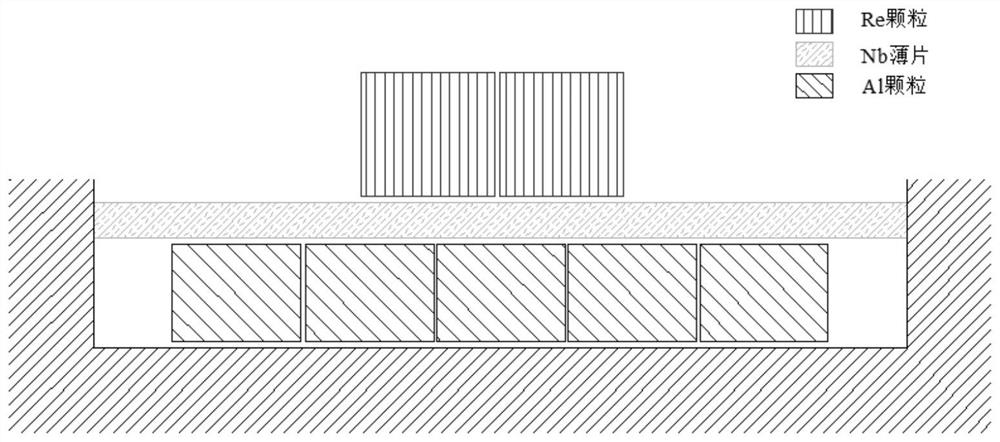

[0024] Charging: place all the Al part...

Embodiment 2

[0027] The Al-Re-Nb ternary alloy containing high melting point and low boiling point elements prepared by the present invention has the following composition in terms of mass percentage: Al 28%, Re 40%, and the balance is Nb.

[0028] The preparation method of described Al-Re-Nb ternary alloy, its steps are as follows:

[0029] Material selection: select Al, Re, Nb three pure metal raw materials with a purity of 99.99%; Al and Re are particles with a particle size of about 2mm, and Nb is a thin sheet with a thickness of about 0.5mm.

[0030] Raw material processing and batching: put the above metal raw materials into acetone solution for ultrasonic cleaning for 15 minutes, take them out and put them in alcohol for ultrasonic cleaning for 15 minutes, and use a hair dryer to dry them immediately after cleaning. The dried raw materials are weighed according to the above mass percentages on an electronic balance with an accuracy of 0.0001.

[0031] Charging: place all the Al par...

Embodiment 3

[0034] The Al-Re-Nb ternary alloy containing high melting point and low boiling point elements prepared by the present invention has the following composition in terms of mass percentage: 20% Al, 50% Re, and Nb as the balance.

[0035] The preparation method of described Al-Re-Nb ternary alloy, its steps are as follows:

[0036] Material selection: select Al, Re, Nb three pure metal raw materials with a purity of 99.99%; Al and Re are particles with a particle size of about 2mm, and Nb is a thin sheet with a thickness of about 0.5mm.

[0037] Raw material processing and batching: put the above metal raw materials into acetone solution for ultrasonic cleaning for 15 minutes, take them out and put them in alcohol for ultrasonic cleaning for 15 minutes, and use a hair dryer to dry them immediately after cleaning. The dried raw materials are weighed according to the above mass percentages on an electronic balance with an accuracy of 0.0001.

[0038] Charging: place all the Al par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com