Method for preventing saline-alkali soil salt return by utilizing salt isolation layer

A technology for saline-alkali land and salt-separating layer, applied in the field of soil treatment and saline-alkali land treatment, can solve the problems of secondary pollution, unfavorable promotion and use, etc., and achieve the effect of increasing soil organic matter, reducing the content of harmful microorganisms, and inhibiting the return of soil salt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this embodiment, the coastal saline-alkali land of Haixing County, Cangzhou City, Hebei Province is used as the experimental site. Lay the salt barrier as follows:

[0030] (1) On the above-mentioned coastal saline-alkali land, delineate the plot to be tested;

[0031] (2) The soil in the experimental area was plowed, and 50 cm thick soil was removed.

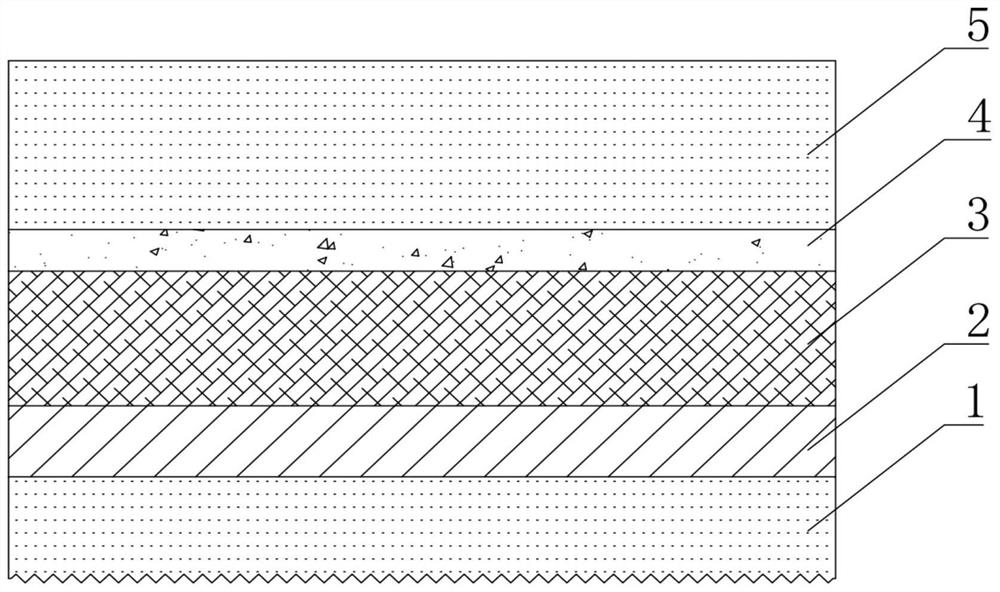

[0032] (3) at figure 1 A 5cm-thick iron tailings salt barrier layer is evenly laid at the position shown in middle 2, and the particle size of the iron tailings does not exceed 1cm;

[0033] (4) at figure 1 A 15cm-thick straw salt barrier layer is evenly laid at the position shown in middle 3, and the selected straw is wheat straw, and the length of the straw does not exceed 5cm;

[0034] (5) at figure 1 A 4cm-thick biochar salt barrier layer is evenly laid at the position shown in middle 4, and the selected biochar is the biochar obtained by pyrolyzing wheat straw in a 400°C pyrolysis furnace in the laboratory; ...

Embodiment 2

[0038] In this embodiment, the coastal saline-alkali land of Haixing County, Cangzhou City, Hebei Province is used as the experimental field. Lay the salt barrier as follows:

[0039] (1) On the above-mentioned coastal saline-alkali land, delineate the plot to be tested;

[0040] (2) The soil in the experimental area was plowed, and 60 cm thick soil was removed.

[0041] (3) at figure 1 A 7cm-thick iron tailings salt barrier layer is evenly laid at the position shown in middle 2, and the particle size of the iron tailings does not exceed 1cm;

[0042] (4) at figure 1 A 17cm-thick straw salt barrier layer is evenly laid at the position shown in middle 3, and the selected straw is wheat straw, and the length of the straw does not exceed 5cm;

[0043] (5) at figure 1 A 6cm-thick biochar salt barrier layer is evenly laid at the position shown in middle 4, and the selected biochar is the biochar obtained by pyrolyzing wheat straw in a 400°C pyrolysis furnace in the laboratory;...

Embodiment 3

[0047] In this embodiment, the coastal saline-alkali land of Haixing County, Cangzhou City, Hebei Province is used as the experimental field. Lay the salt barrier as follows:

[0048] (1) On the above-mentioned coastal saline-alkali land, delineate the plot to be tested;

[0049] (2) The soil in the experimental area was plowed, and 70 cm thick soil was removed.

[0050] (3) at figure 1 A 10cm-thick iron tailings salt barrier layer is evenly laid at the position shown in middle 2, and the particle size of the iron tailings does not exceed 1cm;

[0051] (4) in figure 1 A 20cm-thick straw salt barrier layer is evenly laid at the position shown in 3, wherein the selected straw is wheat straw, and the length of the straw does not exceed 5cm;

[0052] (5) at figure 1 A 8cm-thick biochar salt barrier layer is evenly laid at the position shown in middle 4, and the selected biochar is the biochar obtained by pyrolyzing wheat straw in a 400°C pyrolysis furnace in the laboratory;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com