Process method for single-side welding and double-side forming of Q500qENH weathering resistant steel in alpine region

A single-sided welding double-sided, process method technology, applied in the direction of manufacturing tools, welding equipment, welding accessories, etc., can solve problems such as difficulty in conformity, poor welding performance, etc., to improve production efficiency, excellent low temperature toughness, and improve crack resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A process method for one-sided welding and double-sided forming of Q500qENH weathering steel in an alpine region, the process method comprising:

[0055] (1) Welding surface pretreatment

[0056] (1) Grinding the welding surface and adjacent areas to remove surface rust and other sundries;

[0057] (2) Welding surface cutting treatment

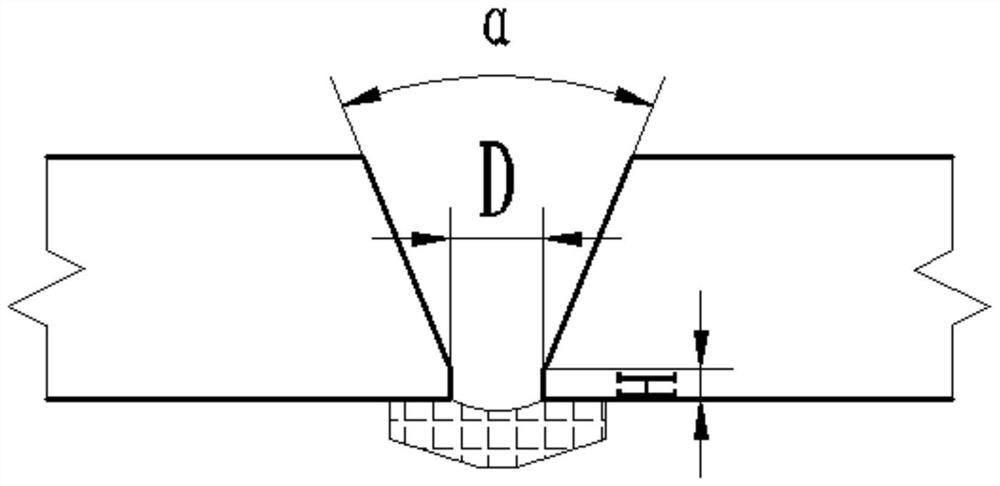

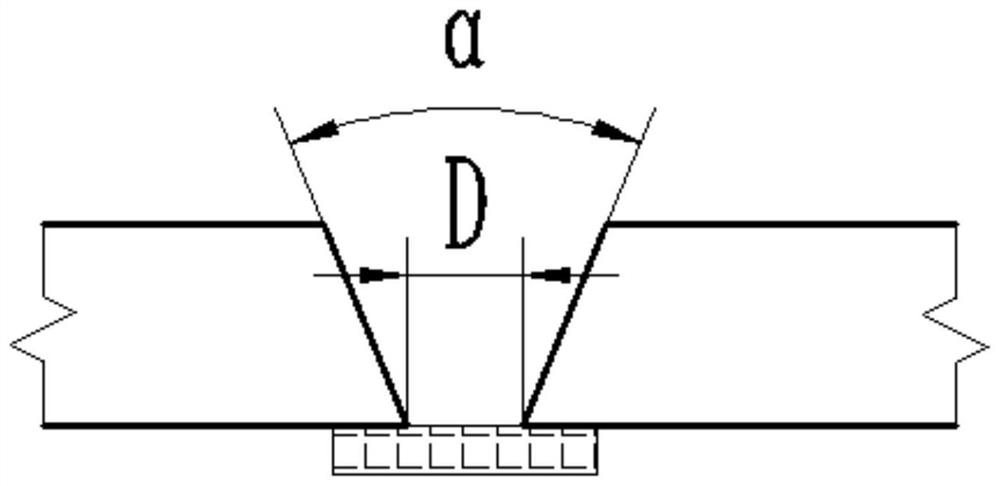

[0058] (2) Cut the two welding surfaces into grooves, the grooves are single-sided "V" grooves, the groove angle α is 40°, the blunt edge height H is 2mm, and the blunt edge distance D is 6mm ;

[0059] (3) Grinding again to remove metal debris;

[0060] (3) Single-sided welding and double-sided forming process

[0061] (4) Welding primer: the welding wire with the tensile strength of the deposited metal ≥ 650MPa is used for the primer, and the gas shielded welding is used to cover the blunt edge;

[0062] (5) Welding filling: Welding filling is carried out in the remaining area, and the welding wire with the tensile strength of th...

Embodiment 2

[0072] A process method for one-sided welding and double-sided forming of Q500qENH weathering steel in an alpine region, the process method comprising:

[0073] (1) Welding surface pretreatment

[0074] (1) Grinding the welding surface and adjacent areas to remove surface rust and other sundries;

[0075] (2) Welding surface cutting treatment

[0076] (2) Cut the two welding surfaces into grooves, the grooves are single-sided "V" grooves, the groove angle α is 45°, the height of the blunt edge is 2mm, and the distance D of the blunt edge is 5mm ;

[0077] (3) Grinding again to remove metal debris;

[0078] (3) Single-sided welding and double-sided forming process

[0079] (4) Welding primer: the welding wire with the tensile strength of the deposited metal ≥ 650MPa is used for the primer, and the gas shielded welding is used to cover the blunt edge;

[0080] (5) Welding filling: Welding filling is carried out in the remaining area, and the welding wire with the tensile st...

Embodiment 3

[0090] A process method for one-sided welding and double-sided forming of Q500qENH weathering steel in an alpine region, the process method comprising:

[0091] (1) Welding surface pretreatment

[0092] (1) Grinding the welding surface and adjacent areas to remove surface rust and other sundries;

[0093] (2) Welding surface cutting treatment

[0094] (2) Cut the two welding surfaces into grooves, the grooves are single-sided "V" grooves, the groove angle α is 45°, the height of the blunt edge is 0, and the distance D of the blunt edge is 5mm ;

[0095] (3) Grinding again to remove metal debris;

[0096] (3) Single-sided welding and double-sided forming process

[0097] (4) Welding primer: the welding wire with the tensile strength of the deposited metal ≥ 650MPa is used for the primer, and the gas shielded welding is used to cover the blunt edge;

[0098] (5) Welding filling: Welding filling is carried out in the remaining area, and the welding wire with the tensile stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com