Corrosion-resistant and flame-retardant treatment process of garden and park organic mulch

An organic mulch, flame retardant treatment technology, applied in wood treatment, wood treatment details, manufacturing tools, etc., can solve the problems of decay fungus and termite erosion, application and promotion of garden green space with uncertainty in use, high surface humidity, etc. Achieve the effect of reducing the risk of fire, stable landscape effect and long-lasting coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

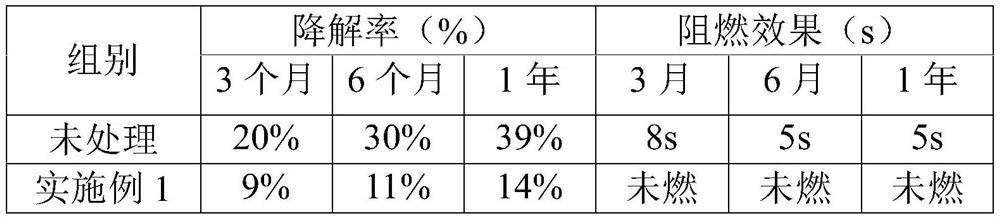

Embodiment 1

[0021] An antiseptic and flame retardant treatment process for garden organic coverings, comprising the following steps:

[0022] (1) Natural drying: spread the organic mulch on the hard ground, control the thickness of the paving at 5-10cm, let it dry in the sun, and ensure that the moisture content is lower than 40% after drying, and the organic mulch is garden waste Sawdust with a particle size of 1-3cm obtained by crushing and sifting thick branches;

[0023] (2) Mix the preservative and water at a ratio of 1:10, and use a vertical mechanical agitator to fully dissolve the powder without precipitation to form a usable preservative solution. The preservative is ACQ antiseptic powder produced by Sanyu Chemical ;

[0024] (3) Place the organic covering in the chamber of the high-pressure atomizing spray equipment, suck the antiseptic solution through the self-priming water pump, and use the air compressor to fully atomize the antiseptic solution, and spray it evenly on the s...

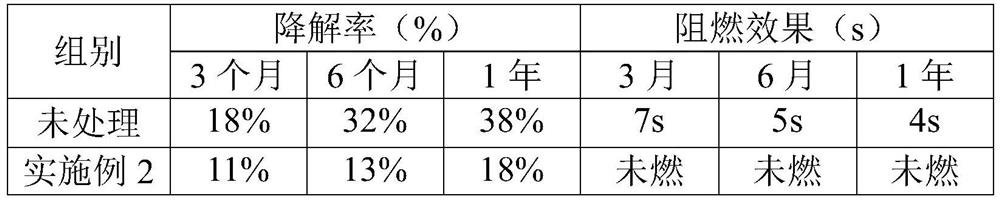

Embodiment 2

[0031] An antiseptic and flame retardant treatment process for garden organic coverings, comprising the following steps:

[0032] (1) Natural drying: spread the organic mulch on the hard ground, control the paving thickness to 5-10cm, and let it dry in the sun. After drying, ensure that the moisture content is lower than 40%. The organic mulch is pine scale organic mulch matter, the particle size is 1-2cm;

[0033] (2) Mix the preservative and water in a ratio of 1:8, and use a vertical mechanical agitator to fully dissolve the powder without precipitation to form a usable preservative solution. The preservative is ACQ antiseptic powder produced by Sanyu Chemical ;

[0034] (3) Place the organic covering in the chamber of the high-pressure atomizing spray equipment, suck the antiseptic solution through the self-priming water pump, and use the air compressor to fully atomize the antiseptic solution, and spray it evenly on the surface of the organic covering. Continuously carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com