Patents

Literature

34results about How to "Function as an oxygen barrier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

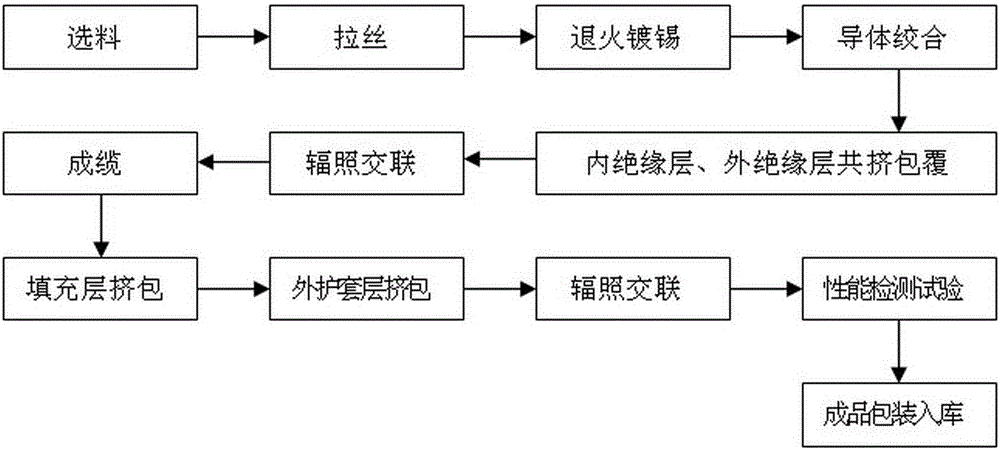

Method for manufacturing low-voltage power cable used in third-generation nuclear power station containment vessel

ActiveCN103578660AImprove insulation performanceImprove flame retardant performanceInsulating conductors/cablesTinningLow voltage

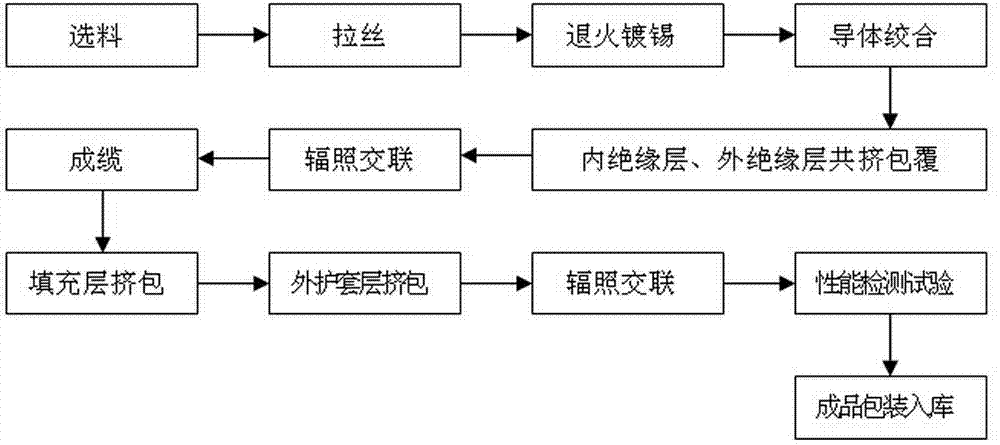

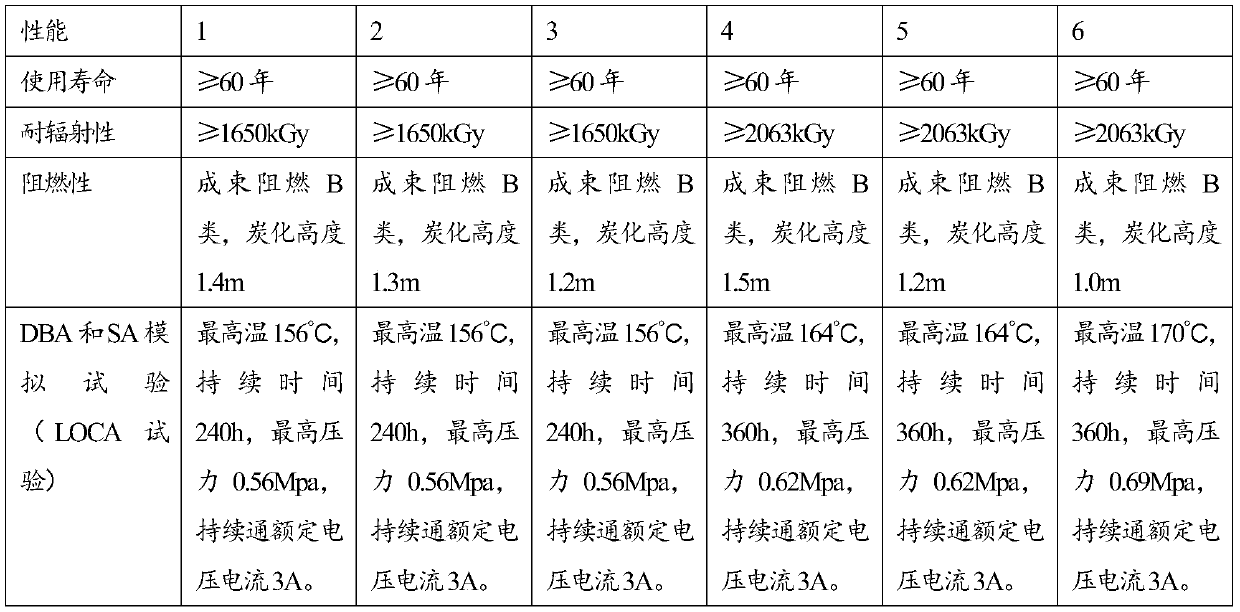

The invention discloses a method for manufacturing a low-voltage power cable used in a third-generation nuclear power station containment vessel, and relates to the field of cable manufacturing. The manufacturing method comprises the steps of material selecting, wire drawing, annealing tinning, conductor stranding, inner insulating layer and outer insulating layer co-extrusion wrapping, irradiation crosslinking, cable forming, packing layer extrusion wrapping, outer sheath layer extrusion wrapping, irradiation crosslinking, performance check testing and finished product packaging and warehousing. Material selecting comprises the steps that copper wire blank for electrical purposes is selected to be used as conductors, and high polymer materials are selected to be used as insulating materials and sheath materials, wherein according to long-time heat resistance evaluation, the service life of the high polymer materials is longer than 60 years. The low-voltage power cable manufactured through the method is greatly improved in service life, irradiation resistance and fire resistance and can operate by more than 60 years under the normal working conditions of a third-generation nuclear power station, and the fact that the functions of the low-voltage power cable can still be executed under DBAs and Post-DBAs.

Owner:SICHUAN MINGXING CABLE

Multifunctional liquid foam used for underground coal mine and using method thereof

InactiveCN103883347AHigh strengthInjection distanceDust removalFire preventionSurface-active agentsNonionic surfactant

The invention belongs to the technical field of coal mine safety, and patricianly relates to multifunctional liquid foam used for an underground coal mine and a using method of the multifunctional liquid foam. The multifunctional liquid foam used for the underground coal mine comprises, by mass, 0.5-10% of crystal whisker stopping agents, 0.5-30% of quaternary ammonium salt cationic surface active agents, 0.5-30% of non-ionic surface active agents and 0-10% of additives, the balance of water. The multifunctional liquid foam preparation method and using method are simple, bring convenience for use and manual operation, and are strong in applicability because of being suitable for mines rich in acid gases like sulfuretted hydrogen and sulfur dioxide, tunnels with large coal spontaneous combustion tendency, mine working faces and the like and particularly suitable for mine goaves.

Owner:LIAONING TECHNICAL UNIVERSITY

A preparing method of an environmental friendly flame-retardant polycarbonate composite material

InactiveCN105348763AChange surface propertiesGood compatibilityPotassium perfluorobutanesulfonatePhosphate

A preparing method of an environmental friendly flame-retardant polycarbonate composite material is disclosed. The method includes mixing nanometer zinc oxide, nanometer titanium dioxide, nanometer aluminium hydroxide, glass fibre, kaolin, nanometer zinc stannate, ferrocene, zinc molybdate, basic sodium aluminium carbonate, calcium stearate, zinc stearate and a silane coupling agent KH-540 to obtain a modified filler; melting and extruding polyvinyl butyral, polyvinylidene fluoride, octafluoro-diphenyl diglycidylether, styrene-acrylonitrile copolymer, melamine resin and the modified filler in a twin-screw extruder to obtain dispersed master batch; adding polycarbonate, the dispersed master batch, tris(2,4-diisobutyl) phosphate, hexaphenoxycyclotriphosphazatriene, potassium perfluorobutanesulfonate, bisphenol A bisphthalonitrile, a plasticizer and an oxidant into a twin-screw extruder, melting and extruding. The composite material prepared by the method is good in heat resistance and excellent in flame retardance.

Owner:ANHUI GUANGYUAN TECH DEV

Fireproof aluminum-plastic panel core material

The invention discloses a fireproof aluminum-plastic panel core material comprising the following components: low-density polyethylene, an ethylene-octene copolymer, aluminum hydroxide, anhydrous magnesium carbonate, calcium stearate, silicon dioxide, a coupling agent, a smoke suppressant, a reinforcing toughener and titanium dioxide. The fireproof aluminum-plastic panel core material prepared by the formula has the advantages of being halogen-free, low-smoke, flame-retardant, and drop-resistant; the panel has flexible rolling property; the fireproof aluminum-plastic panel core material is strong in toughness, easy to mold and good in processability and play roles in thermal insulation, oxygen isolation and smoke suppression; a relatively good flame retardant effect is reached; and continuous automatic production can also be achieved.

Owner:RUGAO BINJIANG URBAN CONSTR INVESTMENT

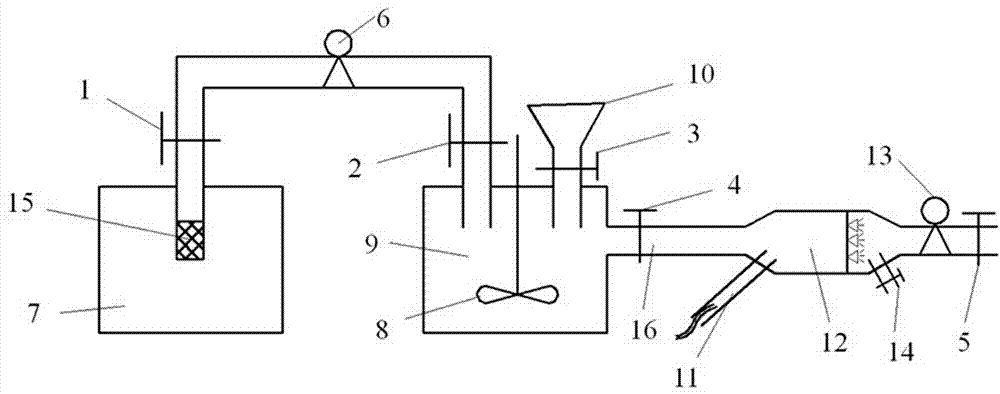

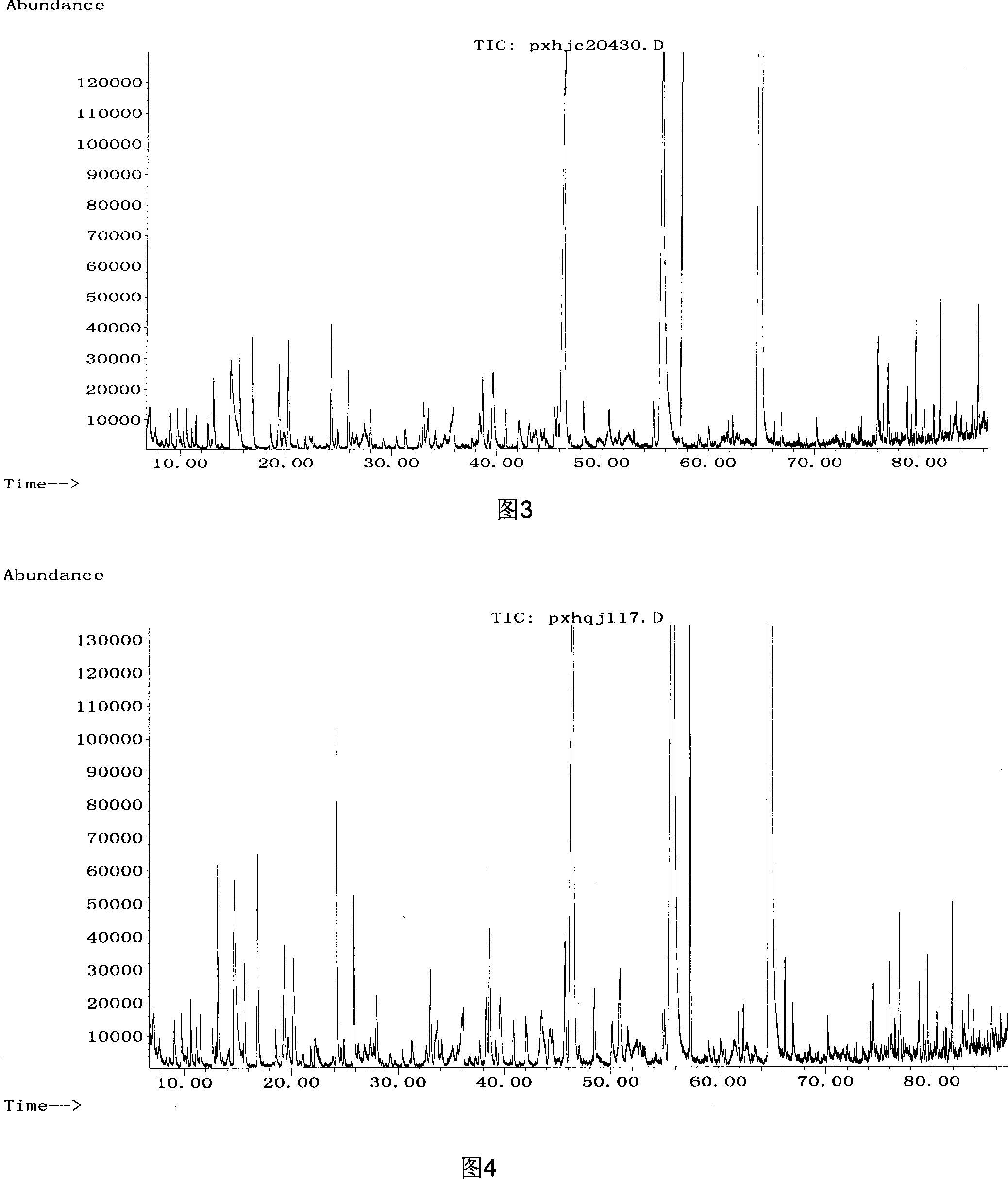

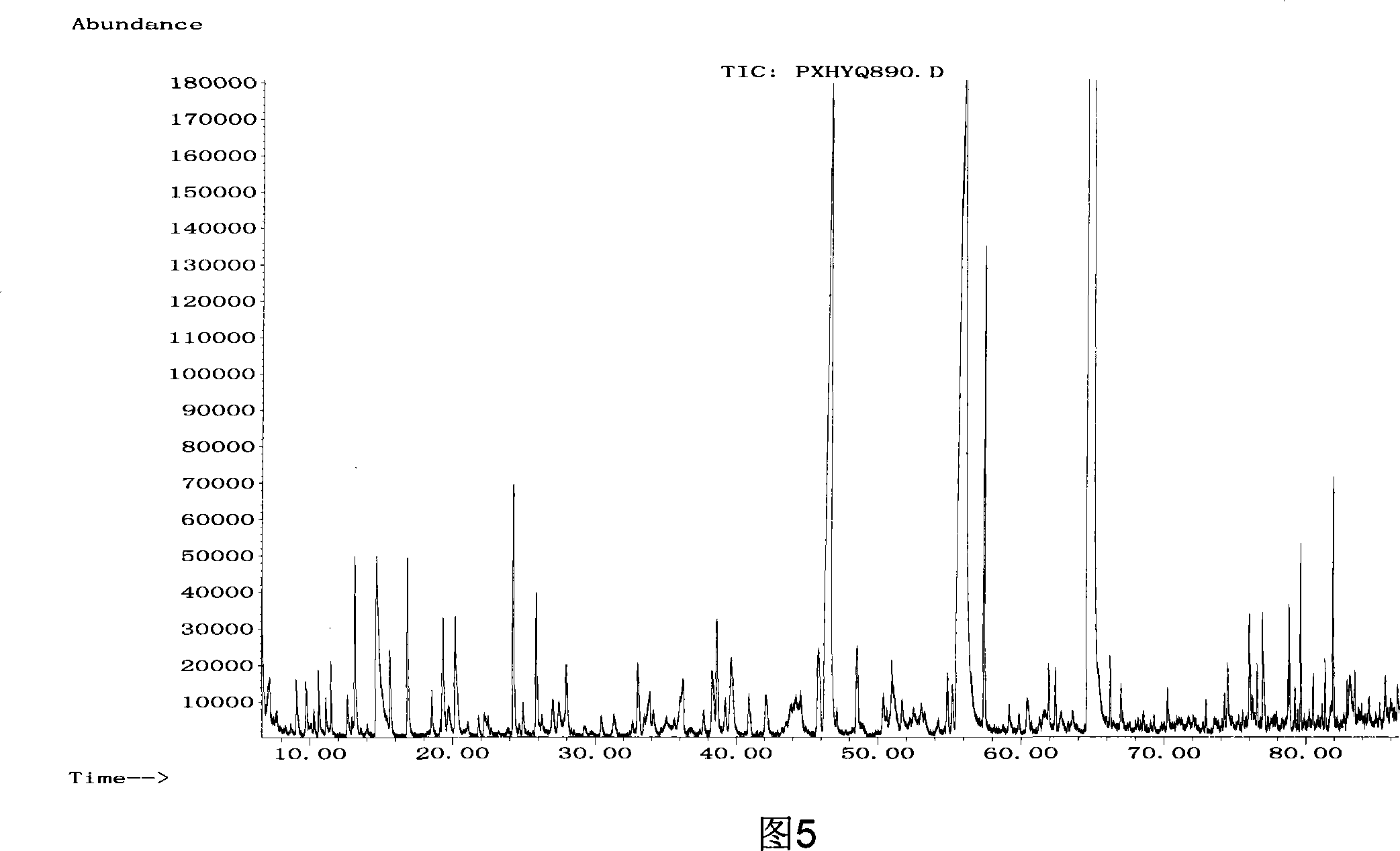

Tobacco leaf pyrolysis device

InactiveCN101187610AUniform and accurate flow rateHigh repeatabilityPreparing sample for investigationPistonCartridge heater

The utility model relates to a high temperature cracking device for tobacco leaves, which comprises a cracking quartz tube and a drum-type heater. The cracking quartz tube is arranged in the drum-type heater, a piston with a push rod is arranged on the air inletting end of the cracking quartz tube, two interfaces are arranged respectively on the cracking quartz tube, a first interface is connected with a protective air flow controller, and a second interface is connected with a vacuum circulating pump. The utility model can effectively eliminate oxygen interference in the air, and the tobacco leaves and other organics can be separated fully, which is beneficial to shorten cracking time, improve efficiency, and lower cost.

Owner:CHINA TOBACCO HUNAN INDAL CORP

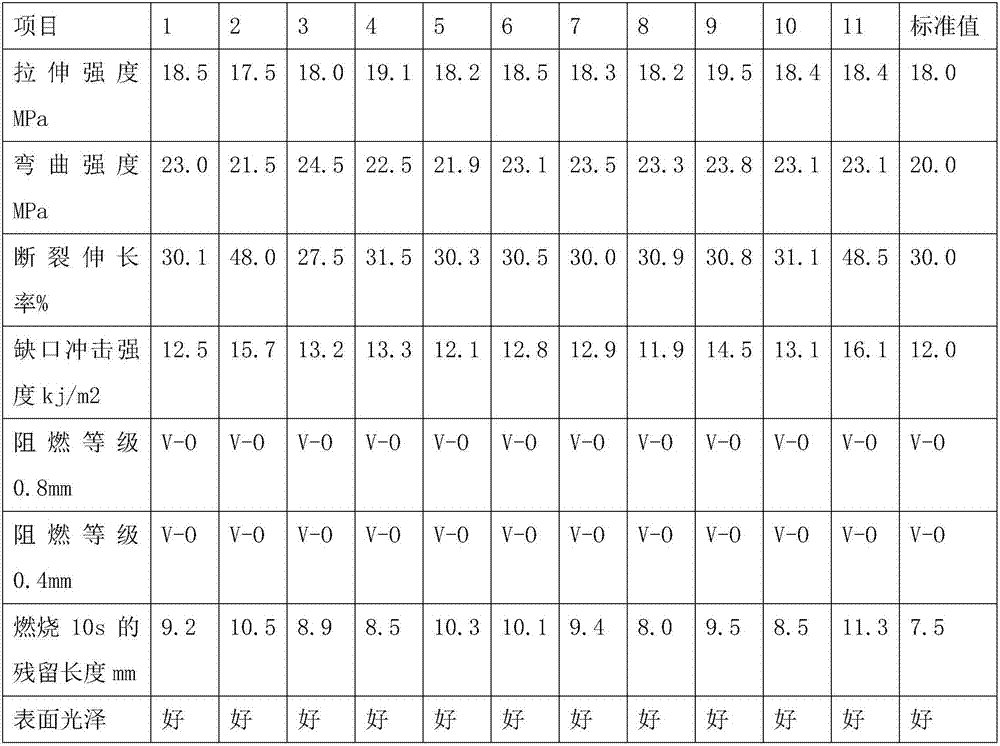

Flame-retardant polypropylene nanocomposite material special for extruded sheet and preparation method of nanocomposite material

The invention provides a flame-retardant polypropylene nanocomposite material special for an extruded sheet and a preparation method of the nanocomposite material, and relates to the field of flame-retardant polymeric material preparation. The nanocomposite material is prepared from, by weight, 65-75 parts of PP, 20-30 parts of flame retardant, 5-8 parts of flame-retardant synergist, 0.5-5 parts of carbon-forming agent, 1-5 parts of inorganic nanometer material, 0.5-1.0 part of antioxidant, 0.3-1.0 part of lubricating agent, 0.1-0.5 part of anti-dripping agent and 0.1-0.5 part of silane coupling agent. A composite flame-retardant system containing the bromated flame retardant, the synergist, the carbon-forming agent and the nanometer material is adopted to be subjected to melt blending and extrusion with the PP, and the flame-retardant PP composite material which is high in fire resistance and malleability is prepared; the flame retardant rating of the composite material reaches 0.4 mm, namely the V-O level (UL94), the elongation percentage is up to 30%, and the material processing property completely meets the requirements of the melt extruded sheet technology.

Owner:SICHUAN GLARY ASIA PLASTIC TECH

Manufacturing method for flame-retardant polyurethane artificial leather

ActiveCN109355923AImprove flame retardant performanceThermally stableFlame-proof filament manufactureMonocomponent synthetic polymer artificial filamentSilyleneCarbon nanotube

The invention relates to the technical field of artificial leather production, in particular to a manufacturing method for a flame-retardant polyurethane artificial leather. The method includes manufacturing base cloth, wherein the raw materials comprise the following components in parts by weight: 70-100 parts of hydroxyl-terminated polybutadiene, 70-100 parts of methylene diphenyl diisocyanate,5-10 parts of vinyltriethoxysilane, 2-10 parts of silane coupling agents, 0.1-0.2 part of dibutyltin dilaurate, 3-5 parts of flame retardants, 5-10 parts of carbon nanotubes, 5-10 parts of hydrophobicfumed silica, 0-5 parts of gardenia fruit juice and 5-10 parts of Silane-based terminated polyether; manufacturing resin layer raw materials, wherein the resin layer raw materials comprise 100 partsby weight of polyurethane elastomer, 0-10 parts by weight of plasticizers, 1-3 parts by weight of compatilizers, 0-20 parts by weight of fillers, 5-10 parts by weight of flame retardants and 3-5 partsby weight of gardenia fruit juice; preforming tape casting coating forming. The invention provides the manufacturing method for the full flame retardant artificial leather, and avoids the influence of an organic phosphine flame retardant on quality in the prior art.

Owner:福建新隆上超纤有限公司

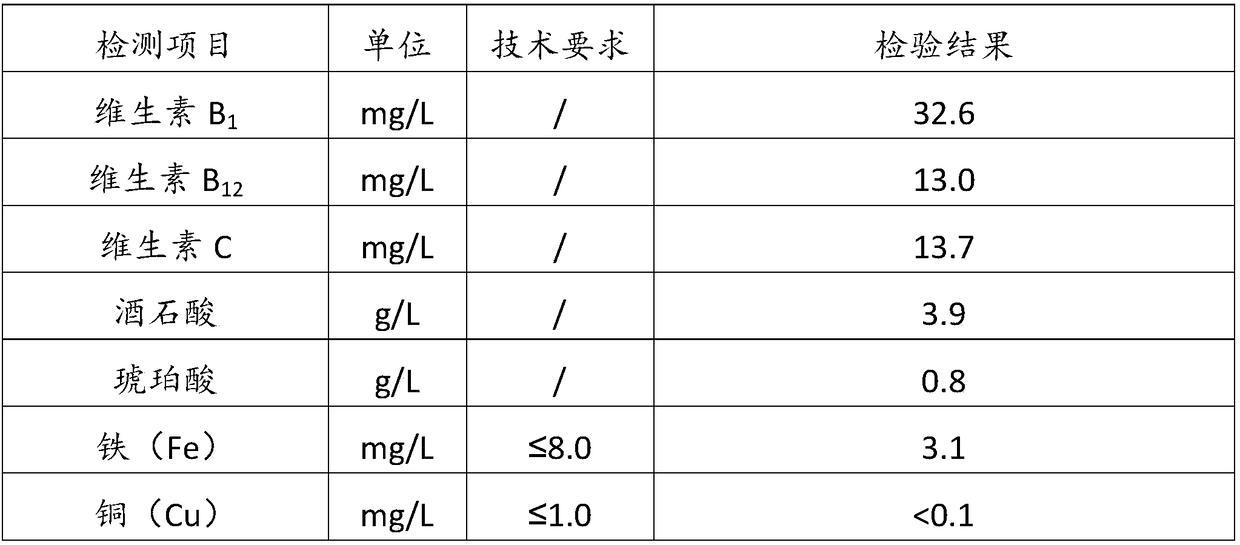

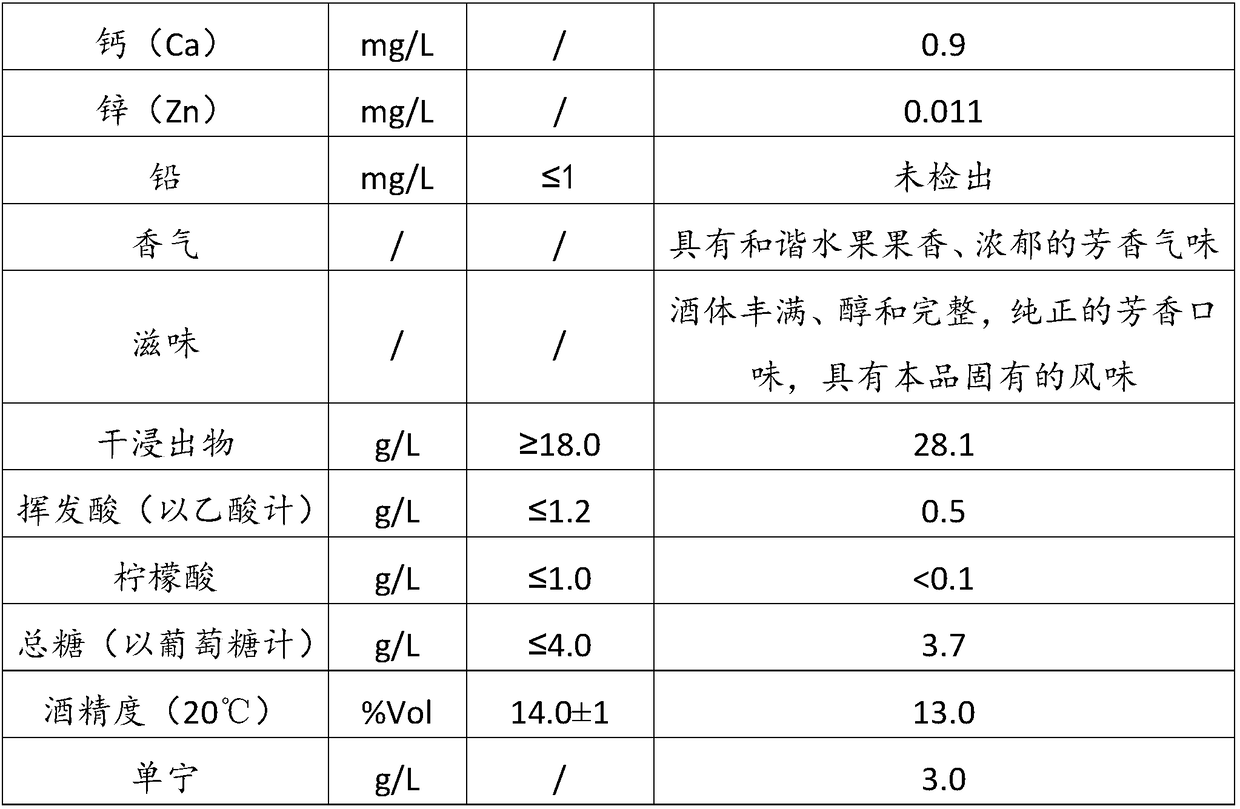

Dry red wine and production process thereof

The invention belongs to the technical field of wine, and particularly provides dry red wine. The dry red wine is prepared by using grapes as raw materials through the technological methods includingsoaking, fermentation, re-soaking, malolactic fermentation, aging and storage. According to the dry red wine provided by the invention, before the grapes enter into a jar, a complete state is kept, low-temperature processing is adopted as much as possible, and the nutrition of the original grapes is kept to a maximum extent, so that oxidation of the grapes is avoided; the high-quality cabernet sauvignon dry red wine which has a complicated and dense fragrance, has a layered, strong-endurance and powerful mouthfeel and has a thick, balanced and a long lasting taste is obtained, the simplification of brewing processes of the dry red wine is broken through, and the local characteristic of the grape raw materials is outstanding.

Owner:北京澳德投资集团有限公司

High-flame-retardance wood fireproof door and making method thereof

InactiveCN102213066AImprove flame retardant and fire prevention functionImprove flame retardant performanceFireproof doorsWood working apparatusMicrowaveTriazine

The invention provides a high-flame-retardance wood fireproof door and a making method thereof. In the making method, a wood door is placed in a vacuum wood softening device tank heated by microwave, and is dipped in high-flame-retardance s-triazine phosphate flame retardant in vacuum such that the flame retardant is fully impregnated in wood gaps of the wood door; a product produced with the making method has the flame retardance higher than a flame retardant limit standard of the first-grade wood fireproof door in China, and has functions of low smoke and no toxicity; and the used flame retardant can ensure that an even flame retardant layer is generated on the surface when high polymer, containing the high flame retardant, in the fireproof door is heated, so that the effects of heat insulation, oxygen isolation and smoke suppression as well as favorable flame retardance are achieved. The making method has the advantages of effectively reducing the production cost and improving the whole flame retardant and fireproof functions of the wood fireproof door, and is accordance with the low smoke and no toxicity development tendency of the fireproof doors at present.

Owner:刘方旭

Lycopene-SOD (Superoxide Dismutase) enteric capsule and preparation method thereof

InactiveCN103919751AImprove stabilityImprove bioavailabilityHydrocarbon active ingredientsPeptide/protein ingredientsEnteric-coated granulesLycopene

The invention discloses a lycopene-SOD (Superoxide Dismutase) enteric capsule and a preparation method thereof. The preparation method is characterized by comprising the following steps: grinding 5wt% of lycopene oil resin into lycopene beta-CD molecular inclusion complex in the presence of beta-CD which is 20 times as much as lycopene oil resin; then preparing lycopene beta-CD molecular inclusion complex into 40-mesh granules; coating the lycopene beta-CD molecular inclusion complex granules with enteric-soluble coated premix auxiliary materials to obtain enteric coated granules. According to the preparation method, easily-oxidized groups in lycopene are embedded in a molecule well of beta-CD for protection so that the stability of products in shelf life is improved; and since the enteric-soluble material is used for coating for further protection so as to prevent lycopene from being damaged in gastric acid and control the release of granules in an enteric canal so as to improve the bioavailability. In order to further improve the stability of SOD and directly conveying the SOD to small intestinal to be absorbed for improving the bioavailability, the molecule embedding is carried out on SOD by beta-cyclodextrin which is at least 50 times as much as SOD according to a grinding method, and then the bedded SOD is prepare into 40-mesh granules, and finally the granules are coated with the enteric-soluble coated premix auxiliary materials to obtain the enteric-soluble granules, so that the stability of the product in the shelf life can be improved, and the damage of the product in the gastric acid can be avoided.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

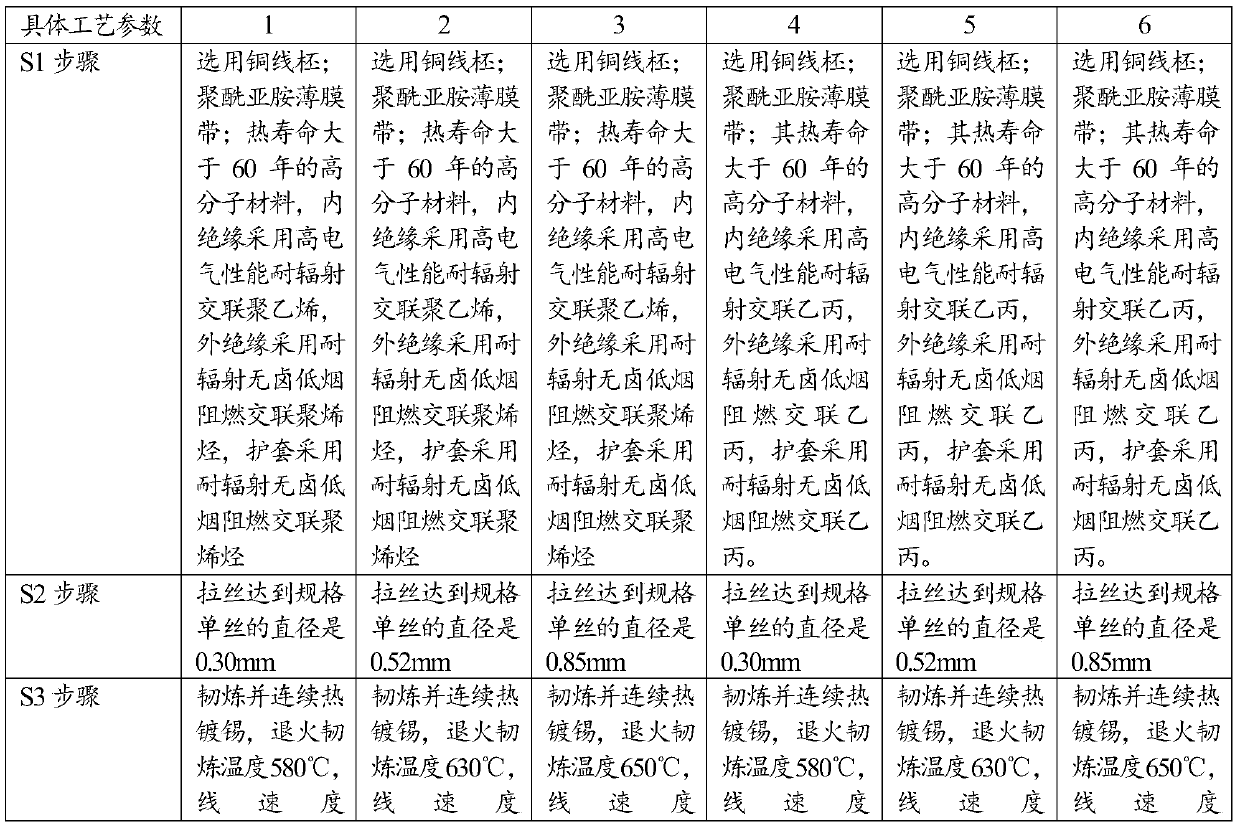

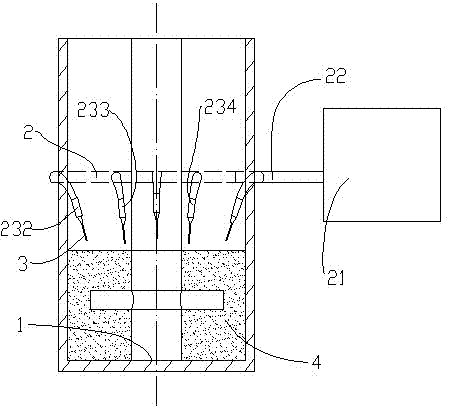

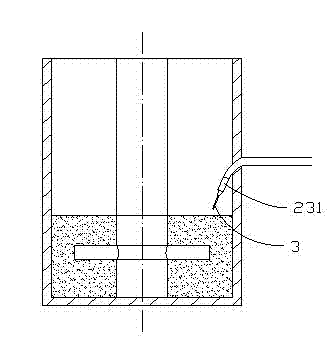

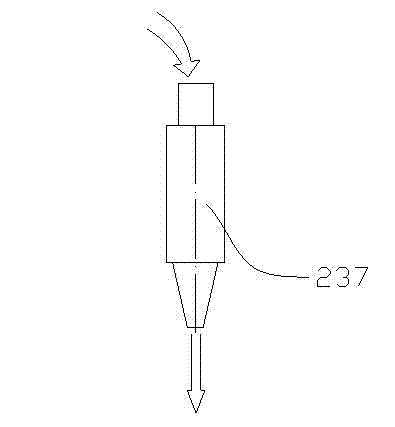

Manufacturing method of control cable used in containment vessel of third-generation nuclear power station

InactiveCN110610783AImprove insulation performanceImprove flame retardant performanceApparatus for heat treatmentInsulating conductors/cablesElectrical conductorNuclear power

The invention discloses a manufacturing method of a control cable used in a containment vessel of a third-generation nuclear power station. The manufacturing method comprises the following steps: S1,material selecting; S2, wire drawing; S3, annealing and tinning; S4, conductor twisting; S5, co-extruding and coating of an inner insulating layer and an outer insulating layer; S6, irradiation cross-linking; S7, insulating wire core wrapping; S8, cabling; S9, extruding of a filling layer; S10, shielding; S11, extruding of an outer sheath layer; S12, irradiation cross-linking; S13, performance inspection test; and S14, finished product packaging and warehousing. According to the invention, the insulation and sheath material is a high polymer material whose thermal life is greater than 60 yearsthrough long-term heat resistance evaluation, the manufactured cable has a service life greater than 60 years under the condition that the conductor works for a long time at a temperature of 90 DEG C, and the cable can tolerate irradiation aging under normal working conditions in a containment vessel of a third-generation nuclear power station and irradiation aging under accident DBA.

Owner:SICHUAN MINGXING CABLE

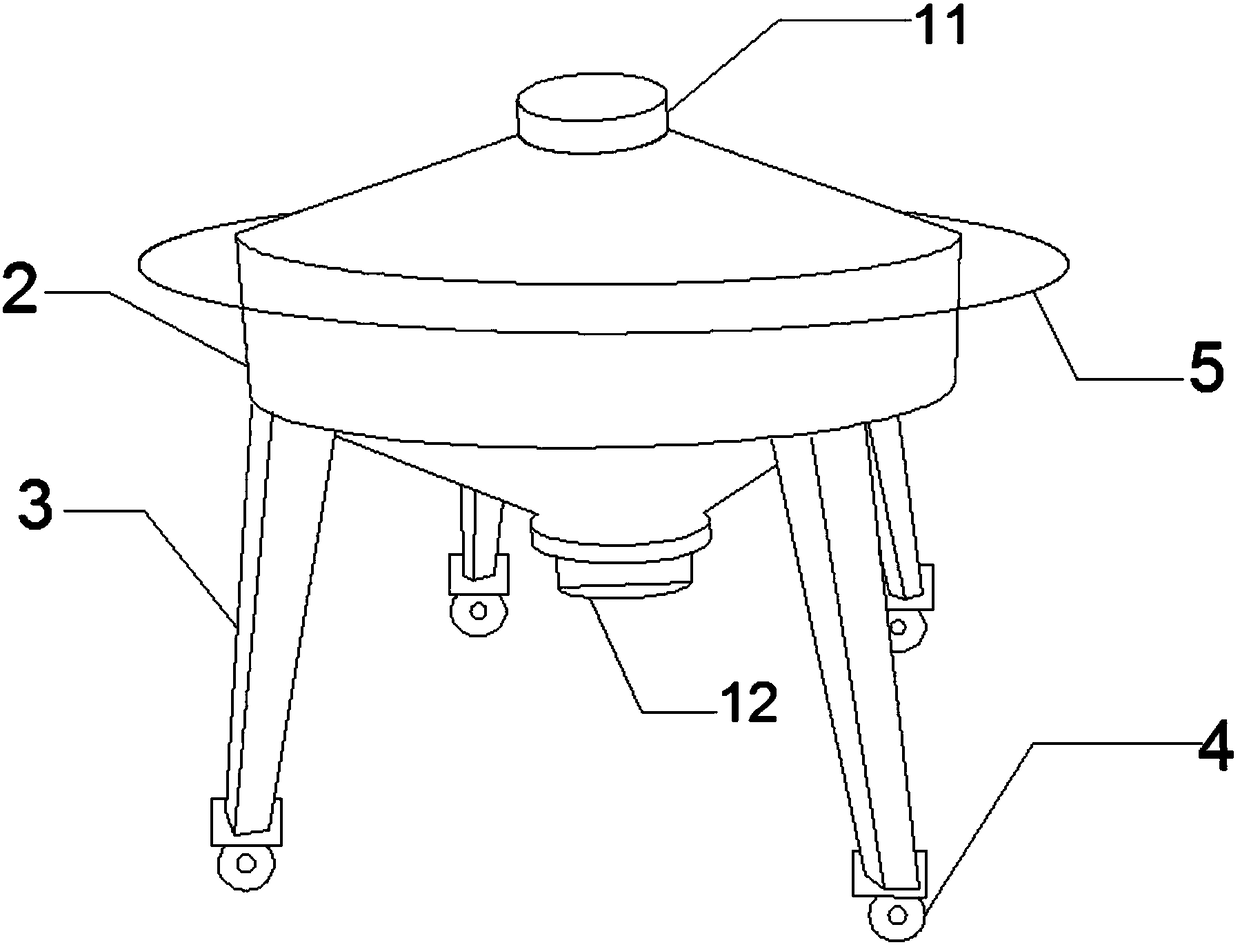

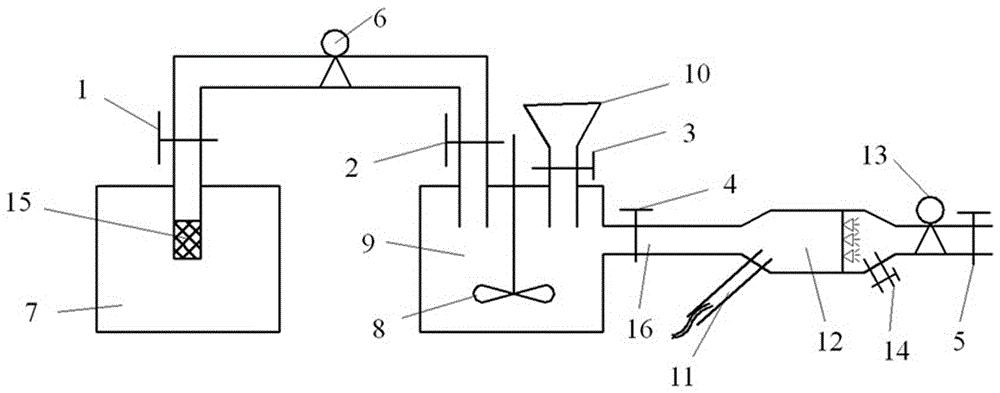

High pressure jet mixing device

InactiveCN102784576AWell mixedThe mixing device is easy for mechanical stirringTransportation and packagingMixersOxygenHigh pressure

The invention provides a high pressure jet mixing device, which belongs to the technical field of stirring and mixing machinery. The high pressure jet mixing device comprises a stirring unit and an injecting unit, wherein the injecting unit comprises a high pressure generating means, a connecting pipeline and one or a plurality of injector heads. While the stirring unit works, injected gas passes through the high pressure generating means so that high pressure gas is generated, and then the high pressure gas passes through the connecting pipeline and is sprayed out from the injector heads connected with the connecting pipeline. The injected gas is sprayed onto stirred liquid, which enables the density of a stirred mixed solution to be reduced and mixing difficulty to be decreased; meanwhile, the function of isolating oxygen is achieved. The high-pressure jet mixing device improves mixing effects, allows production procedures to be simplified and cost to be saved.

Owner:苏州市华元化工有限公司

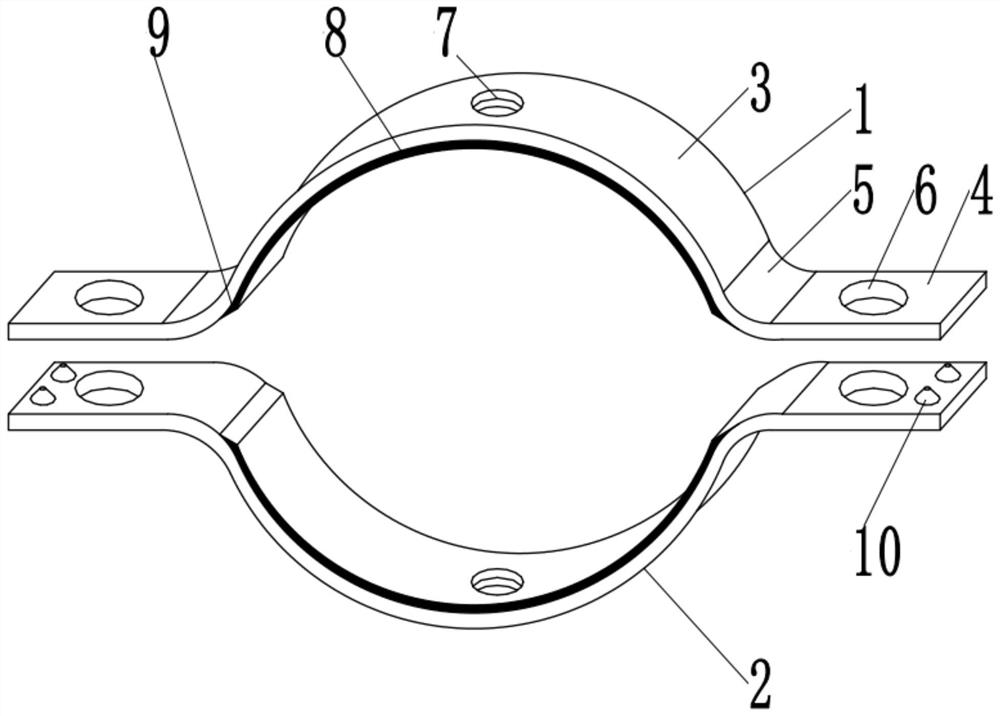

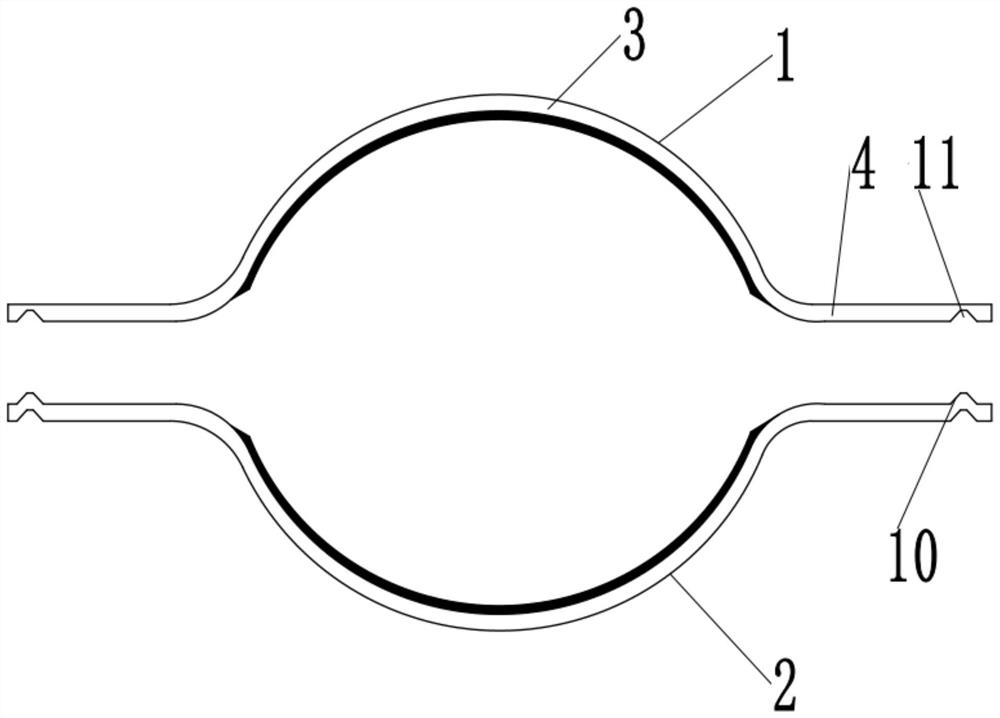

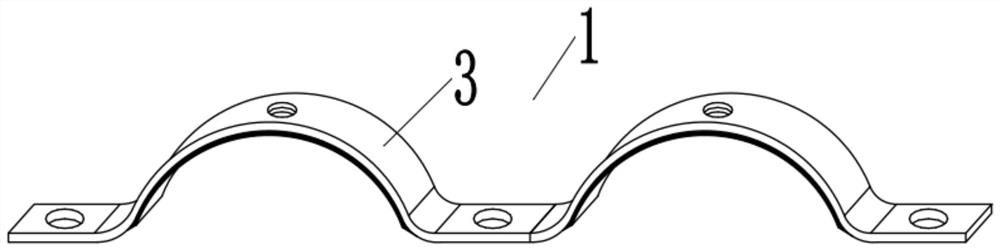

Corrosion-resistant electric iron accessory and production process

InactiveCN112975302AImprove corrosion resistanceExtended service lifeSuspension arrangements for electric cablesCorrosion resistantEngineering

The invention relates to the technical field of electric power iron accessories, in particular to a corrosion-resistant electric power iron accessory and a production process. The corrosion-resistant electric power iron accessory comprises a first electric power iron accessory and a second electric power iron accessory, wherein the first electric power iron accessory and the second electric power iron accessory each comprise an arc-shaped frame, and connecting plates are arranged at the two ends of each arc-shaped frame; and the first electric iron accessory and the second electric iron accessory each comprise an aluminum alloy plate, the two sides of each aluminum alloy plate are ground to form rough surfaces, the surfaces of the rough surfaces are passivated with oxygen isolation layers, one sides of the oxygen isolation layers are plated with anti-corrosion layers in a dip plating manner, one sides of the anti-corrosion layers are provided with wear-resistant layers, and the wear-resistant layers are located on the surfaces of the first electric iron accessory and the second electric iron accessory. The corrosion-resistant electric power iron accessory and the production process have the beneficial effects that the oxygen insulation effect on the surface of the electric iron accessory can be achieved, the surface of the electric iron accessory is prevented from being eroded by oxygen, the corrosion resistance of the electric iron accessory can be improved, the service life of the electric iron accessory is prolonged, the surface abrasion resistance is improved, the surface is prevented from being abraded when the electric iron accessory is used or transported, the production process is simple, and the production cost is low.

Owner:来安县友鹏交通设备有限公司

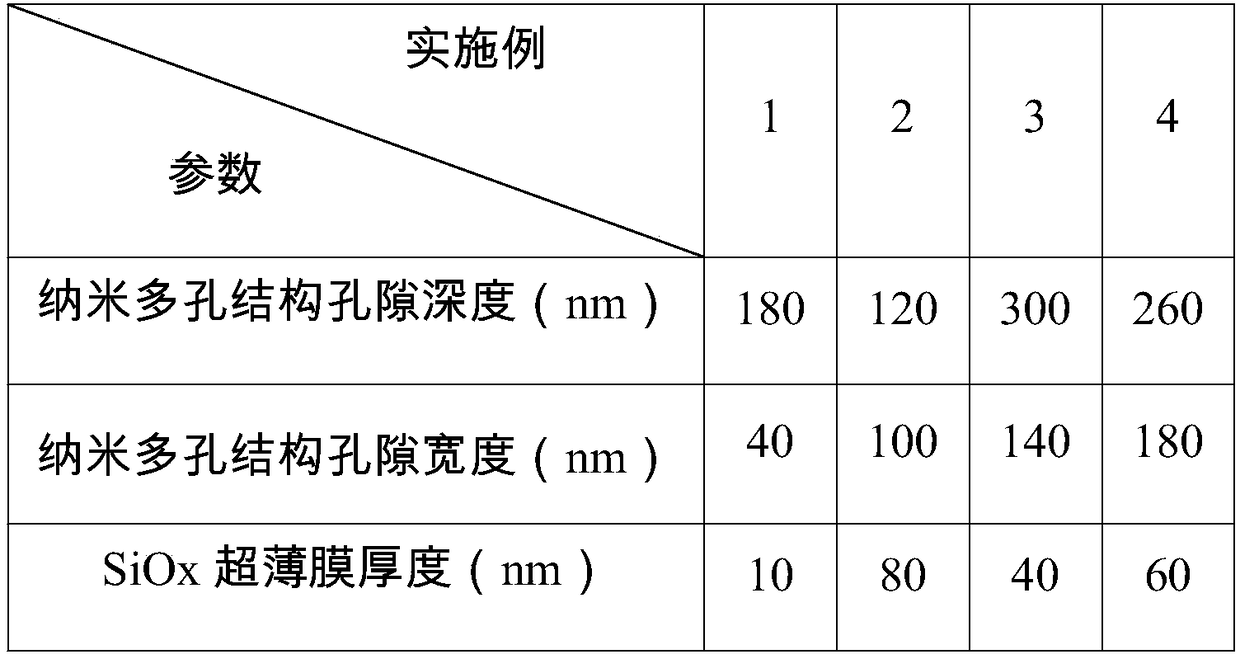

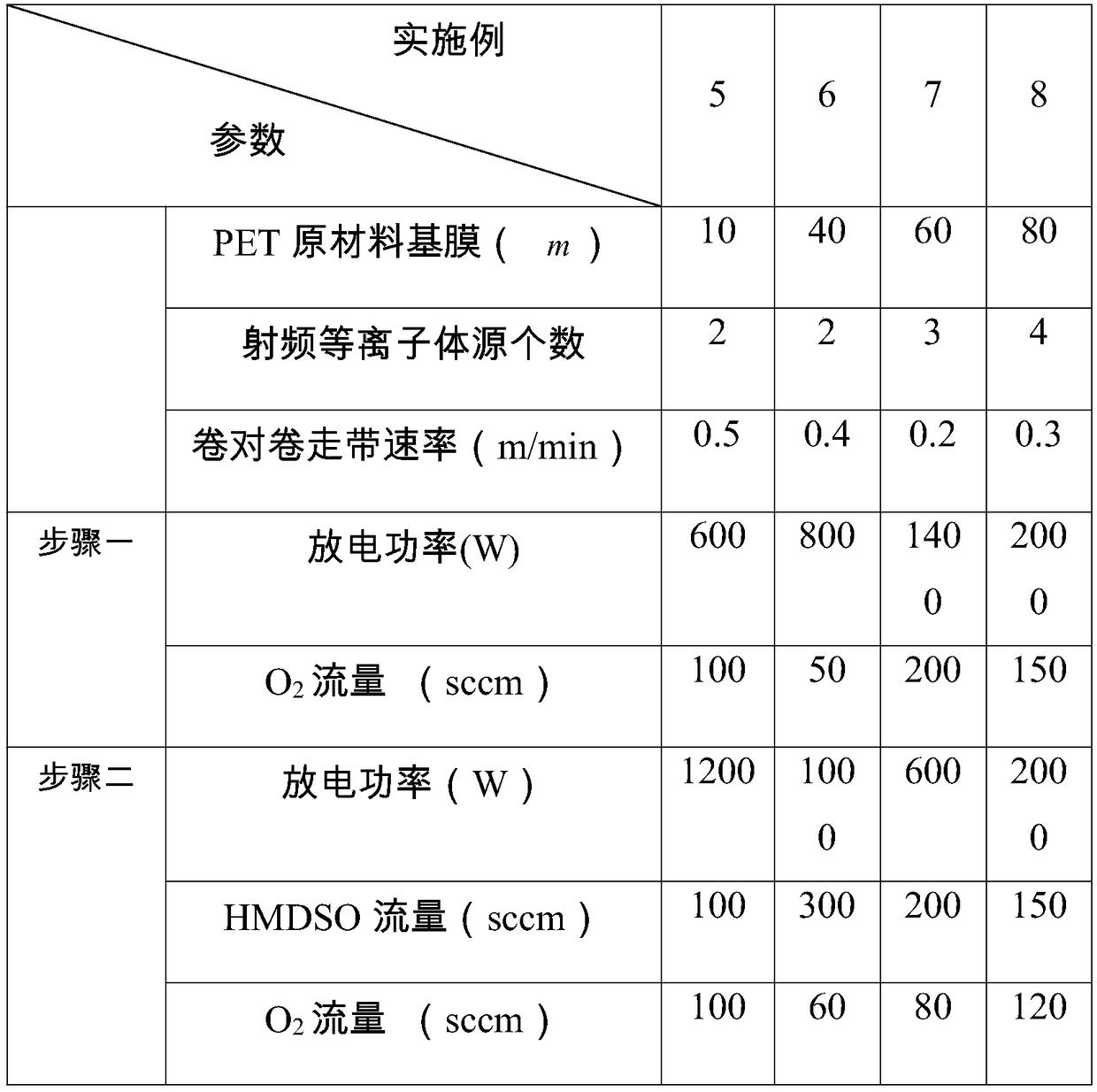

Anti-fogging film, preparation method and application thereof, and application of anti-fogging sticking film

ActiveCN108641113AIncrease roughnessLower contact angleFilm/foil adhesivesCoatingsOxygen plasma etchingSurface structure

The invention discloses an anti-fogging film, a preparation method and application thereof, and application of an anti-fogging sticking film. The anti-fogging film is prepared from a PET (PolyethyleneTerephthalate) base film with a nano-porous structure and a SiOx ultrathin film attached to the nano-porous structure of the PET base film. The preparation method adopts a roll-to-roll process, and comprises an oxygen plasma etching step and a PECVD (Plasma Enhanced Chemical Vapor Deposition) coating step. The anti-fogging film is used for covering gum and a release protective film to prepare theanti-fogging sticking film. The anti-fogging sticking film is to be stuck to bathroom mirrors, automobile front windshields or instrument window glass to achieve the anti-fogging purpose. The antifogging film provided by the invention has the advantages of excellent and durable antifogging performance, easiness in secondary processing, continuous production process and large production capacity.The preparation method disclosed by the invention is applicable to the production of the antifogging film with a nano surface structure. The antifogging film is used for preparing the antifogging sticking film to be further stuck to glass to fulfill the antifogging aim.

Owner:河北芬谷林新材料科技有限公司

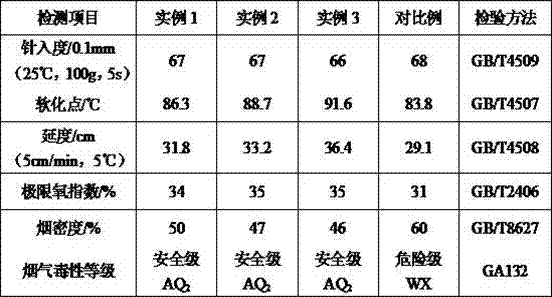

Flame-retarding asphalt and preparation method thereof

The invention belongs to the technical field of preparation of novel materials for roads and in particular relates to flame-retarding asphalt and a preparation method thereof. The preparation method comprises the following steps: enabling petroleum asphalt to react with vinyltrimethoxysilane and an initiator; then adding a solvent and carrying out ultrasonic dispersion; then reacting with a photoinitiator and mercaptoacetic acid to obtain a product; carrying out ultrasonic dispersion on the product and a cobalt acetate solution; then stirring and drying to obtain modified petroleum asphalt; then heating and stirring the petroleum asphalt, nano carbon black, calcium alginate, a coupling agent and a smoke suppressant; finally, naturally cooling to room temperature to obtain the flame-retarding asphalt. The flame-retarding asphalt prepared by the preparation method has relatively good smoke suppression and flame-retarding effects; meanwhile, smoke generated in a combustion process of the flame-retarding asphalt does not cause dangers to human bodies and environment, so that the flame-retarding asphalt is an ideal pavement materials for the roads.

Owner:常州万博金属构件厂

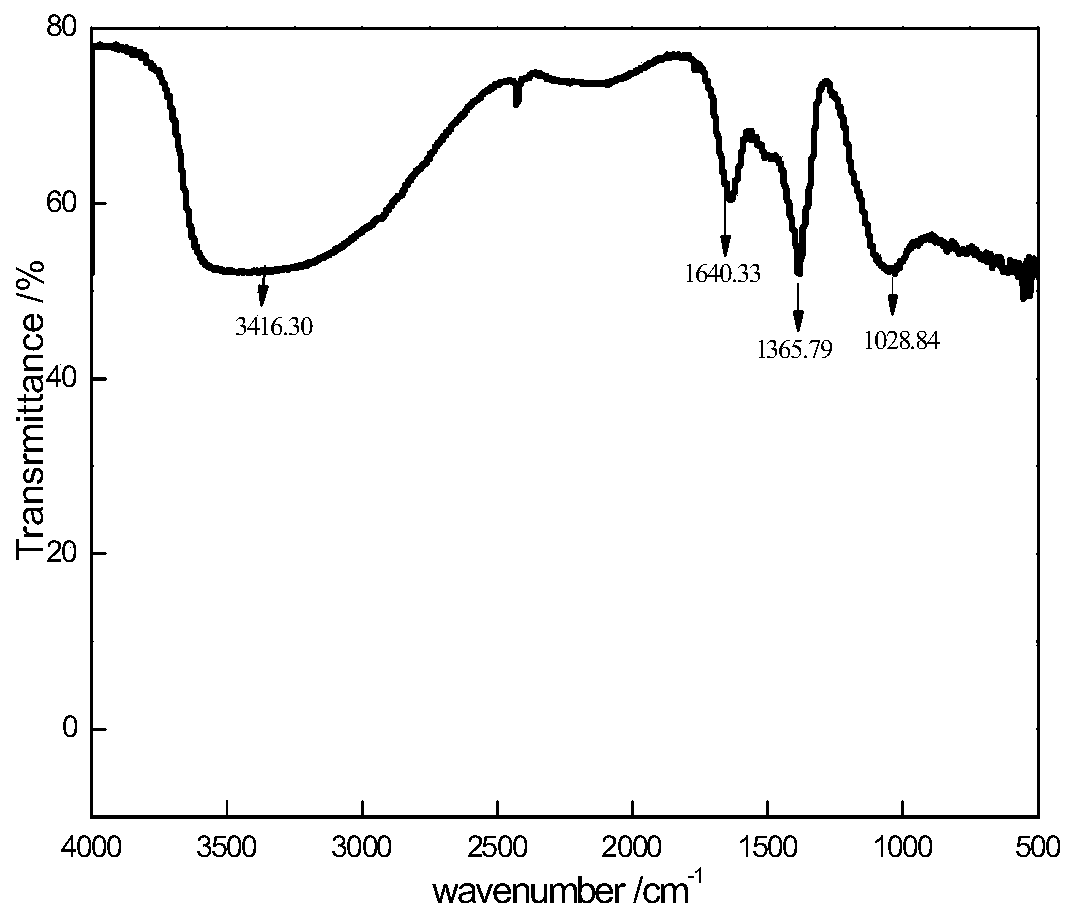

PE film having excellent barrier performance and being antibacterial and preparation method of same

InactiveCN108034113AImprove barrier propertiesImprove antibacterial propertiesLow-density polyethyleneLinear low-density polyethylene

The invention discloses a PE film having excellent barrier performance and being antibacterial, which is prepared from, by weight, 90-100 parts of low density polyethylene, 15-20 parts of metallocenelinear low density polyethylene, 23-26 parts of maleic amide grafted polyethylene, 18-22 parts of polyvinylpyrrolidone, 1-2 parts of glycerol monostearate, 2-5 parts of polyglycerol fatty acid ester,1.3-1.7 parts of an antioxidant, 1.0-1.5 parts of a sterilizing agent, 0.4-0.8 parts of oleamide, 0.6-1.0 part of calcium naphthenate, and 0.9-1.3 parts of modified diatomite. The invention also discloses a preparation method of the PE film having excellent barrier performance and being antibacterial. The PE film has excellent barrier performance and antibacterial performance, can be widely applied to package materials in the fields of medicines, foods and the like. The invention can promote development of the PE films.

Owner:GUANGDONG DEXIN TECH INCUBATOR CO LTD

Novel multilayer composite anti-corrosion material for bolt

InactiveCN109467968AInhibitionReduce tensionAnti-corrosive paintsTectorial membrane(Hydroxyethyl)methacrylate

The invention discloses a novel multilayer composite anti-corrosion material for a bolt, and relates to the technical field of bolt corrosion resistance. The material is multilayer composite anti-corrosion coating liquid for the bolt, and a formula of the material is prepared from the following components in parts by mass: 100 to 150 parts of silicone resin, 1 to 2 parts of an anti-settling agent,12 to 30 parts of zinc phosphate, 50 to 100 parts of ethylene propylene emulsion, 16 to 23 parts of mica iron oxide, 3 to 5 parts of an adhesion promoter and 5 to 6 parts of an anti-skinning agent. According to the novel multilayer composite anti-corrosion material for the bolt, by cooperative use of the silicone resin, the zinc phosphate, the ethylene propylene emulsion, the mica iron oxide, dimethylaminoethyl methacrylate, hydroxyethyl methacrylate, butyl acrylate, phenolic resin and the ethylene propylene emulsion, the whole prepared anti-corrosion coating forms a layer of protective filmwhich effectively protects spirals and avoids severe economical loss of an enterprise due to halt of working equipment caused by corrosion of the bolt.

Owner:张雅慧

Non-halogen flame-resistant sandwich materials with polyethylene for fire-proof aluminium plastic plate and production thereof

ActiveCN100341813CImprove mechanical propertiesImprove toughnessFire proofingLow-density polyethyleneHalogen

A non-halogen and fire-retardant polythene sandwich layer material for fireproof aluminum plate and its production are disclosed. The sandwich layer consists of low-density polythene 15-30 proportion, linear low-density polythene 15-20 proportion, polythene and octylene multi-polymer 3-15 proportion, aluminum hydrate 30-45 proportion, magnesium hydrate 10-15 proportion, fire-retardant synergist 2-25 proportion and coupler 0.5-5 proportion. The process is carried out by mixing aluminum hydrate and magnesium hydrate with coupler separately, mixing at 80-120 DEG C for 15-25mins by high-speed kneader, extruding out into strips by double-screw extruder, granulating by thermal cutting at 100-179 degrees C or cooling and granulating by dicing cutter to obtain final product. It has better machining fluidity, fire-retardant effect and mechanical performance.

Owner:南通金威复合材料有限公司

Preparing method of flame retardant plywood

InactiveCN107984560AImprove thermal stabilityPlay a role in heat insulationWood treatment detailsWood veneer joiningCarbon layerPhosphate

The invention discloses a preparing method of flame retardant plywood. The method comprises the steps of log machining, primary drying, immersion treatment, secondary drying, gluing, pre-pressing, hotpressing and edge cutting and sanding; according to immersion treatment, a fire retardant is prepared into an immersion solution, the solution concentration ranges from 5 to 10%, a single board obtained after primary drying is immersed in the immersion solution to be immersed, the immersion time ranges from 3 hours to 6 hours, and the fire retardant comprises, by weight part, 30 to 40 parts of phosphoric acid, 10 to 20 parts of ammonium dihydrogen phosphate, 8 to 15 parts of squinamide phosphate, 10 to 20 parts of melamine phosphate, 10 to 20 parts of aluminum dihydrogen phosphate, 3 to 5 parts of phosphorus-contained polysiloxane and 2 to 4 parts of methyl phenyl silicone resin. When the fire retardant is heated, phosphorus and silicon synergistic effect is generated, the stable carbon layer is formed in the system, the residual carbon amount reaches above 60%, heat stability is good, heat isolation, oxygen isolation and smoke restraining are generated, and the molten drop preventionaim is achieved.

Owner:黄桂凤

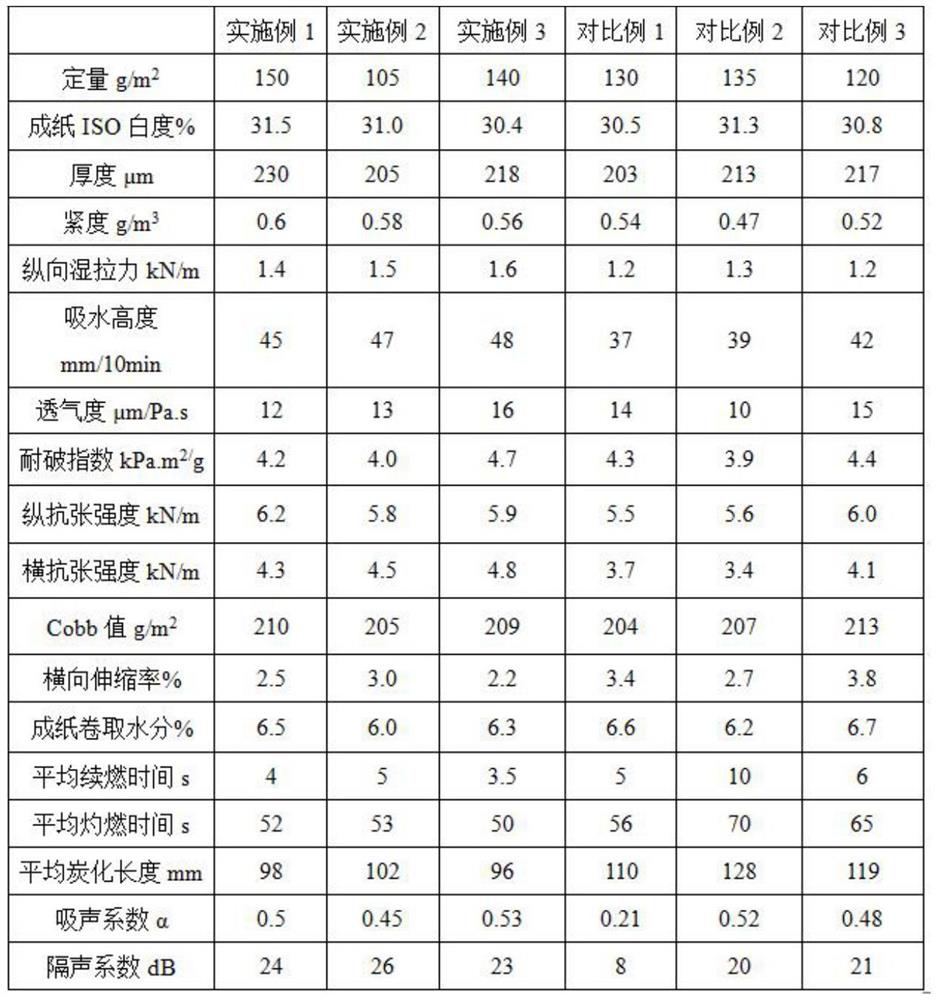

Manufacturing method of fireproof board core paper

InactiveCN111962332AImprove uniformityQuantitatively stableDefoamers additionSpecial paperFiberPapermaking

The invention discloses a manufacturing method of a fireproof board core paper. The invention belongs to the technical field of papermaking, needle-leaved wood, broad-leaved wood and camphorwood are used as fiber raw materials, the preparation method comprises the following steps: cooking, extracting, performing oxygen delignification, performing hydrogen peroxide micro-bleaching, washing, pulping, preparing pulp, slushing, screening and purifying, sizing, dehydrating and forming a net part, squeezing, performing pre-drying, performing surface sizing, performing post-drying, coiling, rewindingand packaging, wherein the ratio of the needle-leaved wood to the broad-leaved wood to the camphorwood is (4.5-5): (3-4): 1. The fireproof board core paper manufactured through the method is good inuniformity, stable in quantification, consistent in tightness, smooth in paper surface, good in laminating performance, free of impurities on the appearance of the paper surface and free of lint on the end face, and the flame retardant property and the sound insulation property of the core paper are improved simultaneously.

Owner:YUEYANG FOREST & PAPER CO LTD

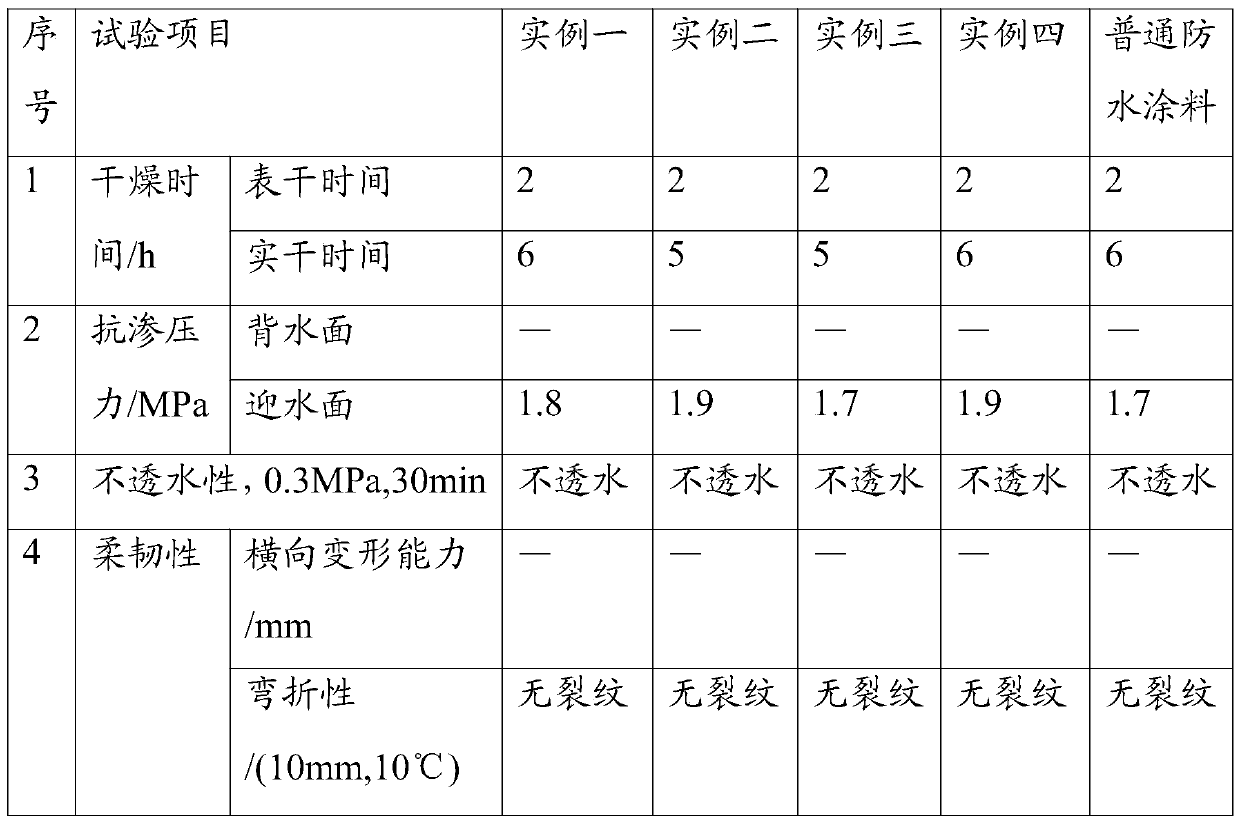

Waterborne waterproof paint and preparing method thereof

The invention discloses waterborne waterproof paint comprising a component A and a component B. The component A is a liquid material, the component B is a powdery material, and the weight ratio of thecomponent A to the component B is 1:(1.2-1.5). The component A comprises, by weight, 90-95% of a styrene-acrylic emulsion, 0.10-0.20% of a preservative, 0.10-0.20% of a dispersing agent, 0.20-0.30% of a defoaming agent, 0.5-1% of an anti-skinning agent and 4-6% of water. The component B comprises, by weight, 25-35% of cement, 25-35% of wollastonite, 35-45% of quartz powder and 0.4-0.7% of a waterreducing agent. An oxime compound is adopted as the anti-skinning agent, free radicals can be generated in the paint film forming process, the anti-skinning agent can catch the free radicals and interrupt the paint film oxidative polymerization effect; the anti-skinning agent quite easily volatiles, cannot stop the polymerization film formation of the free radicals, and extremely easily volatilesunder the high vapor pressure, the space in a tank is filled with generated vapor, an oxygen isolation effect is realized, and the skinning phenomenon of the waterproof paint in the use process is effectively prevented.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

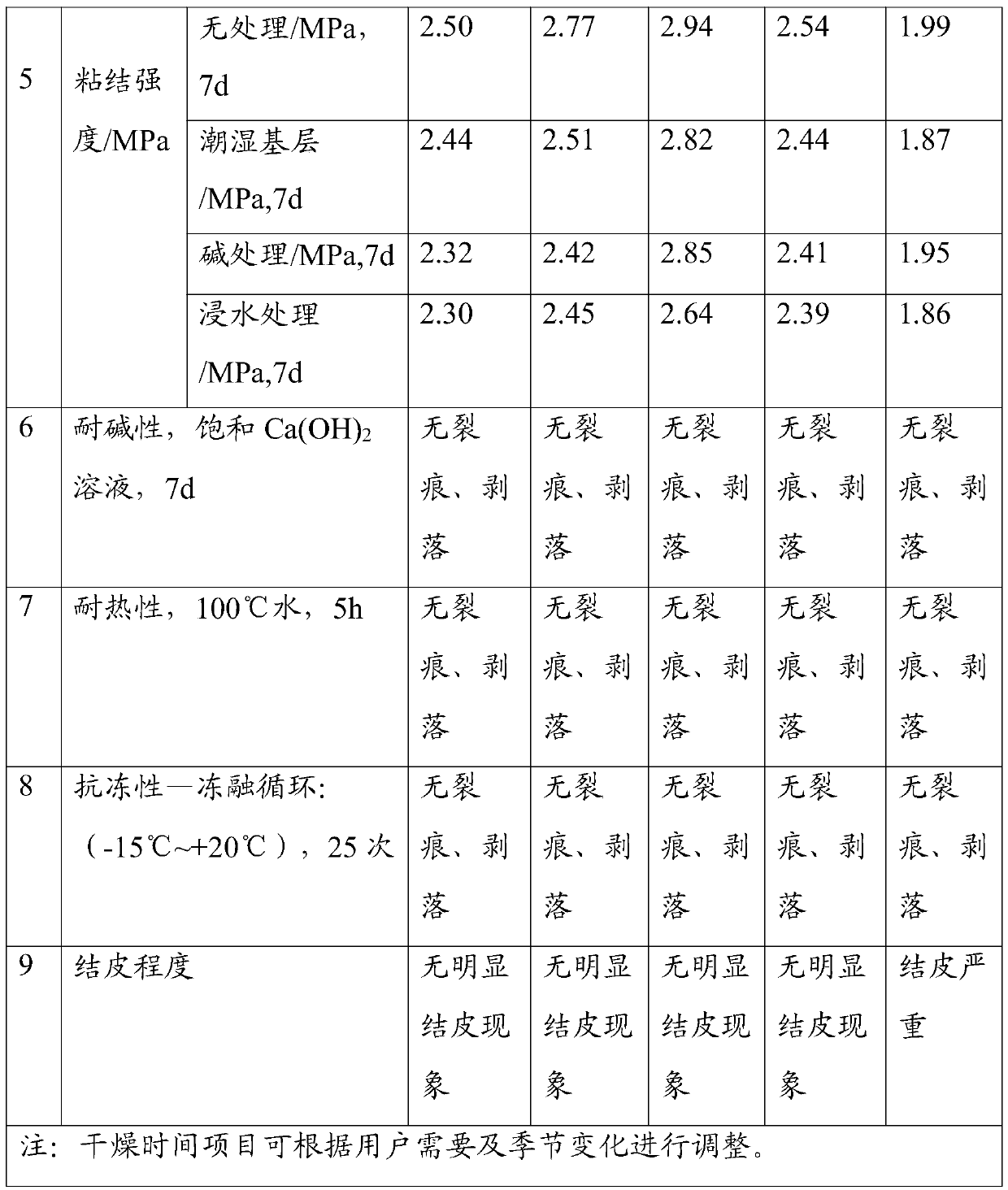

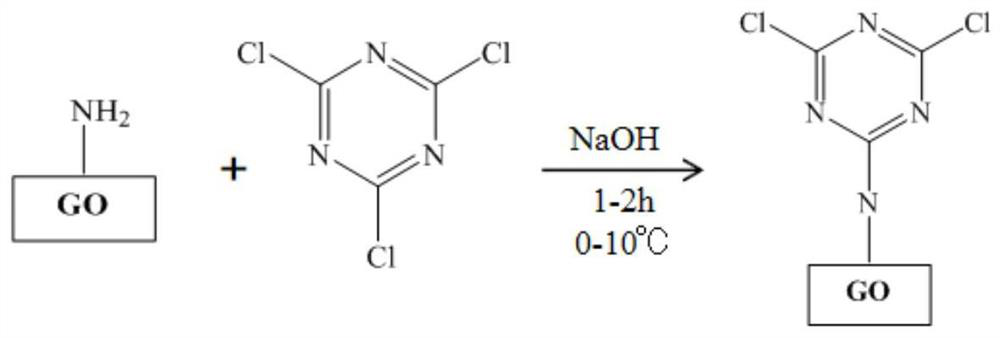

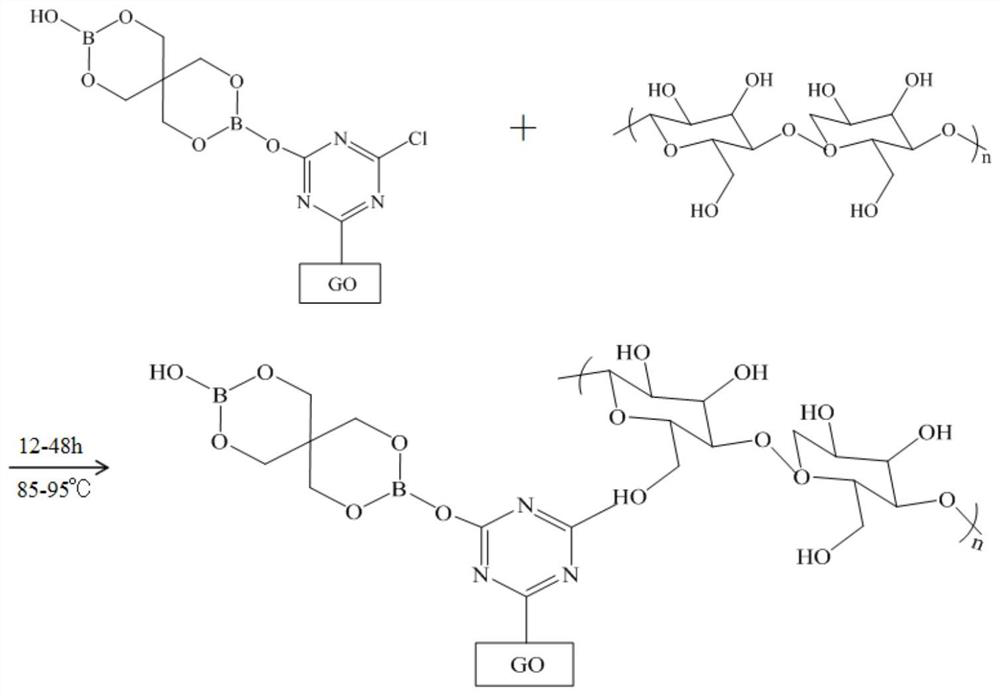

Functionalized graphene modified polypropylene wood-plastic plate and preparation method thereof

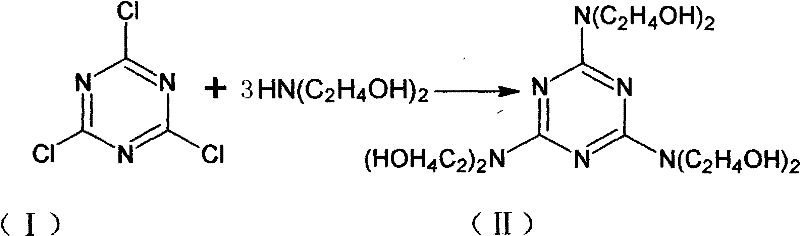

The invention discloses a functionalized graphene modified polypropylene wood-plastic plate and a preparation method thereof. The functionalized graphene modified polypropylene wood-plastic plate comprises the six steps: preparing ethanediamine modified graphene oxide, preparing cyanuric chloride grafted graphene oxide, preparing pentaerythritol borate, preparing borate-triazine grafted graphene oxide, preparing functionalized graphene and preparing the functionalized graphene modified polypropylene wood-plastic plate. The grafted borate, triazine and cyclodextrin functional groups can achieve a synergistic effect during flame retardance, under the synergistic effect of the three functional groups, the effects of heat insulation, oxygen resistance and smoke suppression can be achieved, and the flame retardance of the polypropylene wood-plastic plate is remarkably enhanced; in addition, borate, triazine and cyclodextrin groups grafted on the surface of the graphene oxide can effectively improve the compatibility of the graphene oxide and polypropylene, the problem that graphene is prone to agglomeration in the polypropylene wood-plastic plate is solved, and escape of polypropylene thermal degradation products can be slowed down due to the high specific surface area of the graphene; and the thermal stability of the polypropylene material is improved.

Owner:深圳市兴至鑫科技有限公司

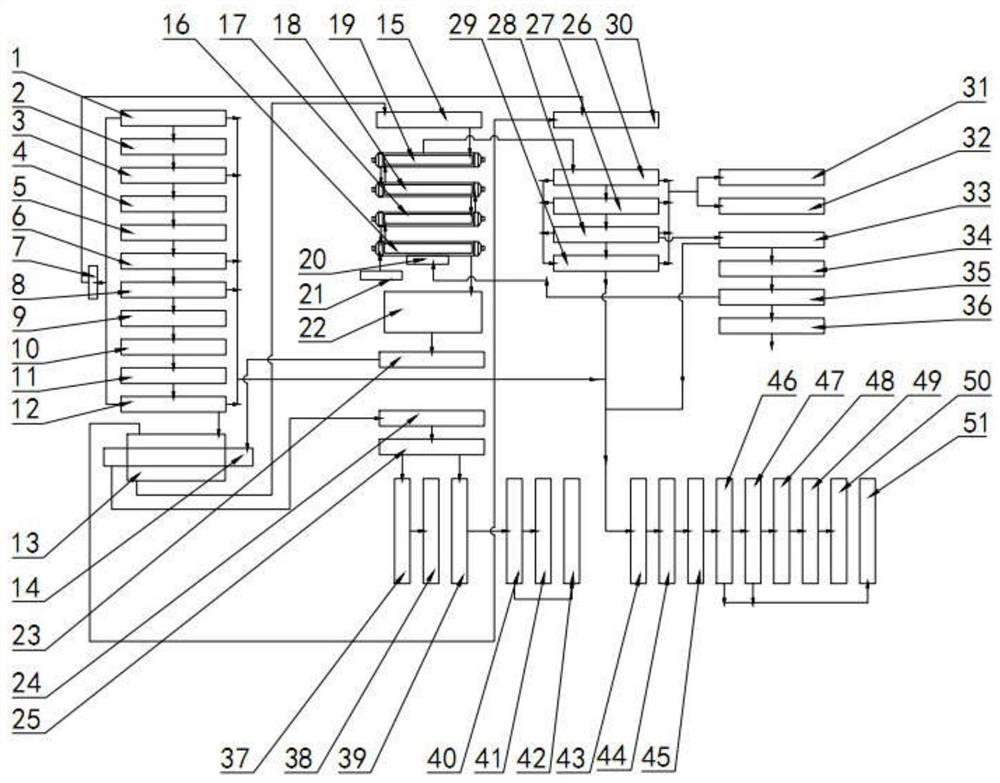

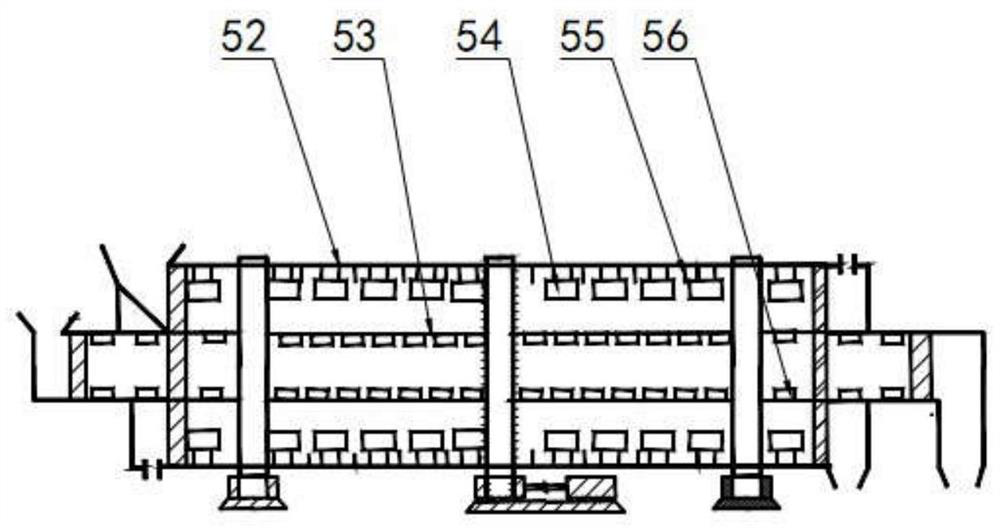

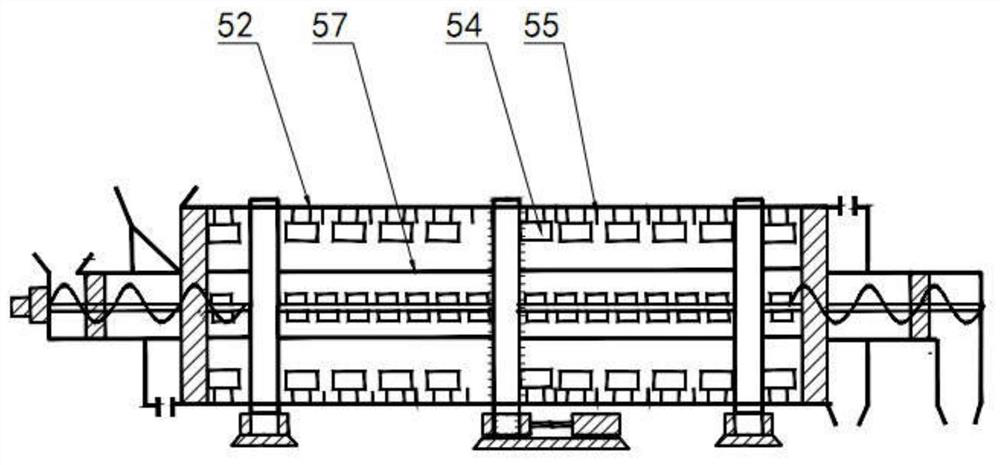

Organic solid waste low-temperature anaerobic cracking treatment device, process and application of process

PendingCN112029520ANo secondary pollutionNo need to classifyBiofuelsSpecial form destructive distillationExhaust gas emissionsProcess engineering

The invention discloses anorganic solid waste low-temperature anaerobic cracking treatment device, a process and application of the process and relates to the technical field of organic solid waste treatment. An organic solid waste pretreatment device is connected with a feeding opening of a drying device through a first screw extrusion feeder; a discharging opening of the drying device is connected with an organic solid waste feeding opening of a cracking reaction device through a second screw extrusion feeder. an organic solid waste discharging opening of the cracking reaction device is connected with an organic solid waste cooling device through a high-temperature material dry discharging device; a waste gas treatment device is connected with a waste gas discharging opening of the organic solid waste pretreatment device; and a cracking gas outlet of the cracking reaction device is connected with a cracking gas treatment device. The organic solid waste pretreatment device is used forpretreating organic solid waste, then the cracking reaction device is used for cracking the dried organic solid waste, and finally cracking gas generated by the cracking reaction device enters the cracking gas treatment device to be collected and treated, so that cracking gasification of the organic solid waste is realized, fuel gas is obtained, and resource utilization of the organic solid wasteis realized.

Owner:陶旭庆

A kind of multifunctional liquid foam used in underground coal mine and its application method

InactiveCN103883347BHigh strengthInjection distanceDust removalFire preventionSurface-active agentsCoal

The invention belongs to the technical field of coal mine safety, and patricianly relates to multifunctional liquid foam used for an underground coal mine and a using method of the multifunctional liquid foam. The multifunctional liquid foam used for the underground coal mine comprises, by mass, 0.5-10% of crystal whisker stopping agents, 0.5-30% of quaternary ammonium salt cationic surface active agents, 0.5-30% of non-ionic surface active agents and 0-10% of additives, the balance of water. The multifunctional liquid foam preparation method and using method are simple, bring convenience for use and manual operation, and are strong in applicability because of being suitable for mines rich in acid gases like sulfuretted hydrogen and sulfur dioxide, tunnels with large coal spontaneous combustion tendency, mine working faces and the like and particularly suitable for mine goaves.

Owner:LIAONING TECHNICAL UNIVERSITY

A kind of epoxy acrylate flame retardant material of zinc-aluminum-tin-containing phosphate intercalation layered hydroxide and preparation method thereof

InactiveCN110218508BImprove flame retardant performanceImprove mechanical propertiesFireproof paintsEpoxy resin coatingsPorous carbonPhosphate

The invention discloses an epoxy acrylate flame retardant material containing zinc-aluminum-tin phosphate intercalation layered hydroxide and a preparation method thereof. The zinc-aluminum-tin-containing phosphate intercalation layered hydroxide is prepared. And use it as a carbon-forming catalyst and flame retardant, and compound it with zinc chloride, acrylamide, acrylic acid, and epoxy acrylate to prepare an epoxy acrylate intumescent flame retardant material containing phosphorus, nitrogen, zinc, aluminum, and tin. , is a low-addition high flame-retardant acrylate transparent material, which combines phosphorus and metal Lewis acid to synergistically catalyze the combustion of EA coating to form a uniform porous carbon foam layer, which plays the role of oxygen barrier, heat insulation, smoke suppression, Preventing dripping and other effects can not only improve the flame retardant performance of epoxy acrylate flame retardant materials, but also improve its mechanical properties, and the preparation method is simple and the cost is low. It can be used for decorative fire resistance of wooden furniture and ancient wooden buildings. In the field of combustion coatings, the market prospect is broad.

Owner:PUTIAN UNIV

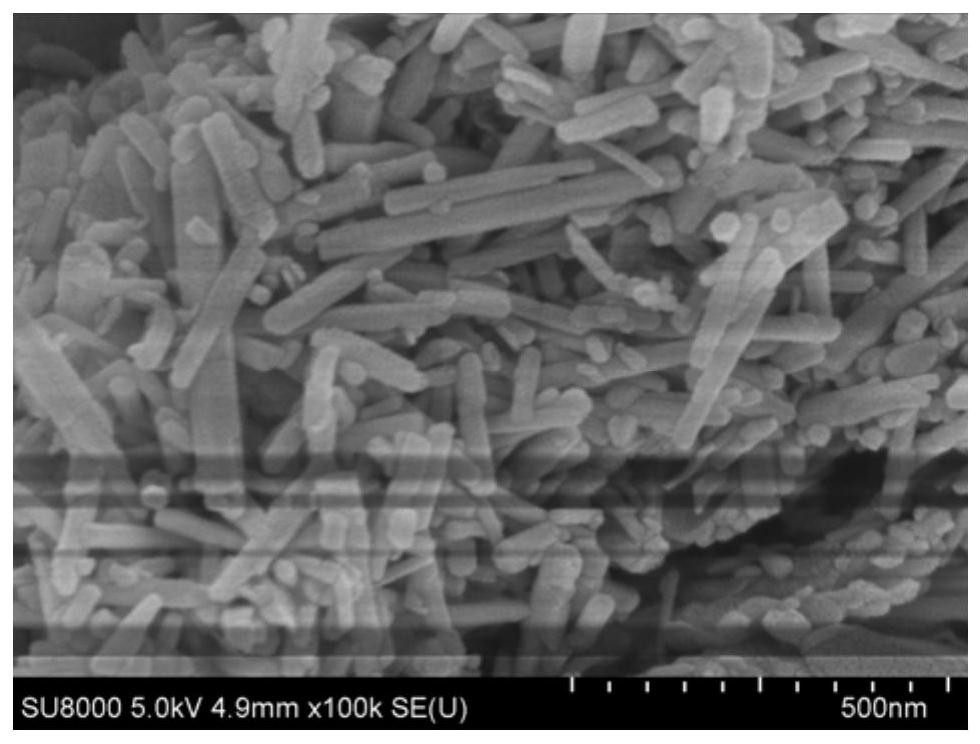

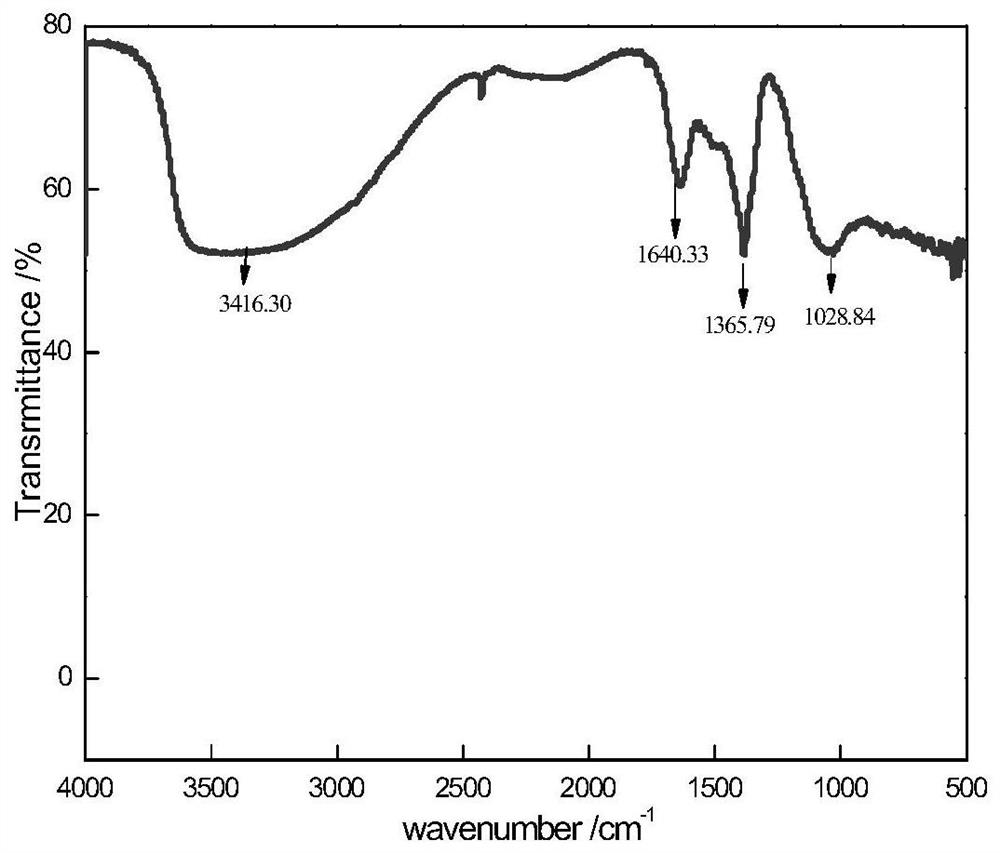

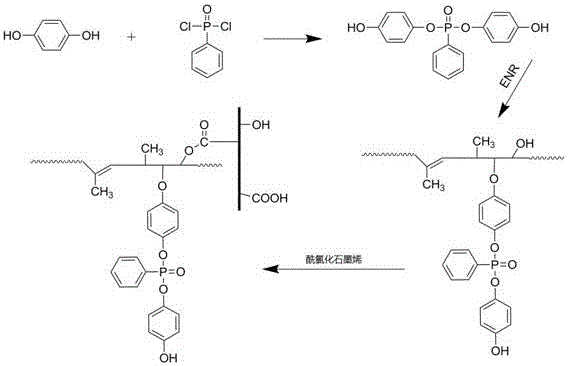

Flame-retardant and reinforced integrative natural rubber and preparation method thereof

Flame-retardant and reinforced integrative natural rubber and a preparation method thereof relate to rubber and a preparation method thereof. The raw material formula consists of natural rubber(NR), epoxy natural rubber(ENR), chloroformylated graphene, a self-made flame retardant, stearic acid, zinc oxide, accelerator CZ, antioxidant 4010, carbon black and liquid paraffin. Epoxy natural rubber and natural rubber have a similar structure and good interfacial compatibility therebetween, ring-opening reaction between epoxy groups on the surface of epoxy natural rubber and active hydrogen can be performed. Therefore, according to the invention, the self-made high-efficient and environment-friendly flame retardant is grafted to the ENR matrix, chloroformylated graphene is employed to perform reinforcement modification on the ENR modified by the flame retardant, and then the flame retardant and graphene are grafted to the rubber matrix by co-vulcanization of natural rubber and epoxy natural rubber during processing. According to the invention, dispersibility of the flame retardant and graphene is well improved and thus flame retardancy and mechanical properties of the material are easy to improve.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Phosphate-radical-intercalated layered-like hydroxide containing zinc, aluminum and tin, preparation method thereof and application thereof in flame retardant material

InactiveCN110218508AImprove flame retardant performanceImprove mechanical propertiesFireproof paintsEpoxy resin coatingsPhosphateOxygen

The invention discloses phosphate-radical-intercalated layered-like hydroxide containing zinc, aluminum and tin, a preparation method thereof and application thereof in a flame retardant material. Thephosphate-radical-intercalated layered-like hydroxide containing zinc, aluminum and tin is prepared and compounded, as a char-forming catalyst and a flame retardant, with zinc chloride, acrylamide, acrylic acid and epoxy acrylate to prepare an epoxy acrylate intumescent flame retardant material containing phosphorus, nitrogen, zinc, aluminum and tin, with the material being a low-additive-contenthighly flame retardant acrylate transparent material. A uniform porous charcoal foam layer is generated when phosphorus and a metal Lewis acid are combined to catalyze EA coating combustion in a synergistic manner, thus playing roles of oxygen isolation, heat insulation, smoke suppression, molten drop preventing, and the like, improving flame retardant performance of an epoxy acrylate flame retardant material and improving mechanical performance of the epoxy acrylate flame retardant material. The preparation method is simple and cheap. The hydroxide and the material can be used for the fieldof decorative surface type fireproof flame retardant coating for wooden furniture and ancient wood buildings, and have wide market prospects.

Owner:PUTIAN UNIV

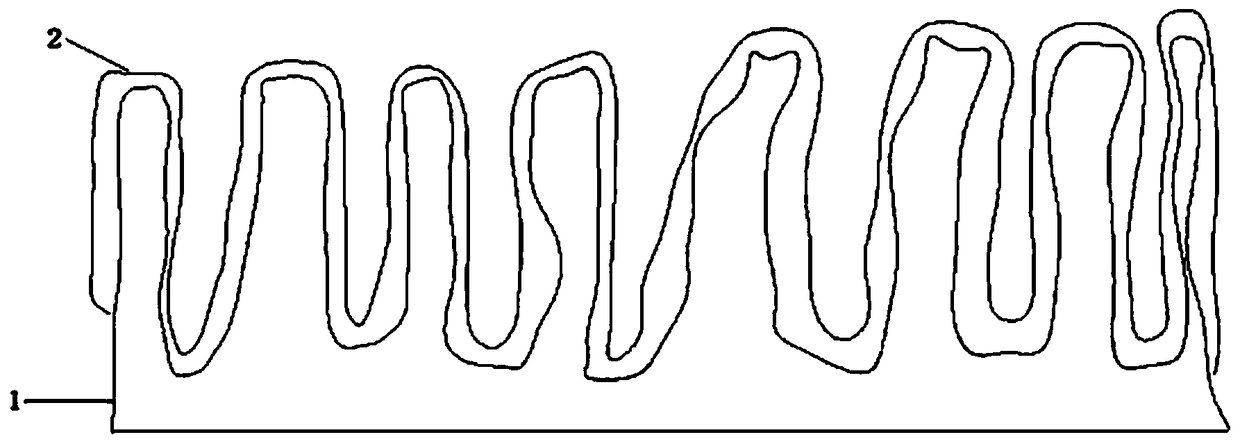

Heat preservation tube shell with heat preservation and fire resistance and production method thereof

The invention belongs to the technical field of heat preservation material production, and discloses a heat preservation tube shell with heat preservation and fire resistance. The heat preservation tube shell is prepared from the following raw materials in parts by weight: 30-40 parts of polystyrene particles, 25-30 parts of resin, 20-25 parts of a phosphorus-based flame retardant, 20-25 parts ofan inorganic environment-friendly flame retardant and 3.5-4.2 parts of a curing agent. The heat preservation tube shell provided by the invention has various good properties, and can be widely appliedto hot-cold water pipes, air conditioner pipelines, solar water heater water pipelines, heating thermal pipelines and liquefied natural gas pipelines and other pipeline heat preservation systems.

Owner:穆振奎

Manufacturing method of low-voltage power cables used in containment of third-generation nuclear power plants

ActiveCN103578660BImprove insulation performanceImprove flame retardant performanceInsulating conductors/cablesTest performanceLow voltage

The invention discloses a method for manufacturing a low-voltage power cable used in the containment of a third-generation nuclear power plant, and relates to the field of cable manufacturing. The manufacturing method of the present invention includes: material selection—wire drawing—annealing and tinning—conductor stranding—inner insulation layer and outer insulation layer co-extrusion coating—irradiation crosslinking—cable formation—filling layer extrusion—outer sheath layer extrusion Packaging—irradiation crosslinking—performance inspection test—finished product packaging and warehousing, the material selection refers to the selection of electrical copper wire blanks for conductors, and the selection of insulation and sheath materials that have been evaluated for long-term heat resistance and have a thermal life of more than 60 years. Polymer Material. The low-voltage power cables manufactured by the manufacturing method of the present invention are greatly improved in service life, radiation resistance, and flame retardancy, and can be operated for more than 60 years under the normal working conditions of the third-generation nuclear power plants, and ensure that the design basis accident DBA and Post‑DBA is still able to perform its functions.

Owner:SICHUAN MINGXING CABLE

Copper smelting processing method

InactiveCN104911374AReduce productionReduce pollutionRotary drum furnacesCrucible furnacesIsolation effectSmelting process

The invention discloses a copper smelting processing method, including the following processing steps: feeding, covering, melting, and dragging residue, the covering is performed by completely covering a melted copper liquid with a graphite phosphorus piece, a large graphite phosphorus piece is used for covering in the copper processing smelting process, covering is comprehensive, oxygen isolation effect is effective, burning speed is slow, the production cost is effectively reduced, waste production amount is less, dragging residue is not needed, product quality is improved, and the pollution to the environment is reduced.

Owner:ANHUI YONGJIE COPPER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com