Functionalized graphene modified polypropylene wood-plastic plate and preparation method thereof

A polypropylene and wood-plastic board technology, which is applied in the field of flame-retardant wood-plastic boards, can solve the problems of poor flame-retardant performance and poor mechanical properties of polypropylene wood-plastic boards, improve compatibility, improve thermal stability, and solve the The effect of easy reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method for functionalized graphene modified polypropylene wood-plastic board, comprising the steps of:

[0034] (1) Preparation of ethylenediamine-modified graphene oxide: 0.4g graphene oxide was added to 300mL N,N-dimethylformamide, dispersed uniformly, then 300mL ethylenediamine was added thereto, dispersed uniformly, at 60 Stir and reflux at a constant temperature in a warm water bath at ℃ for 6 hours. After the reaction is completed, the reaction product is washed and dried to obtain ethylenediamine-modified graphene oxide;

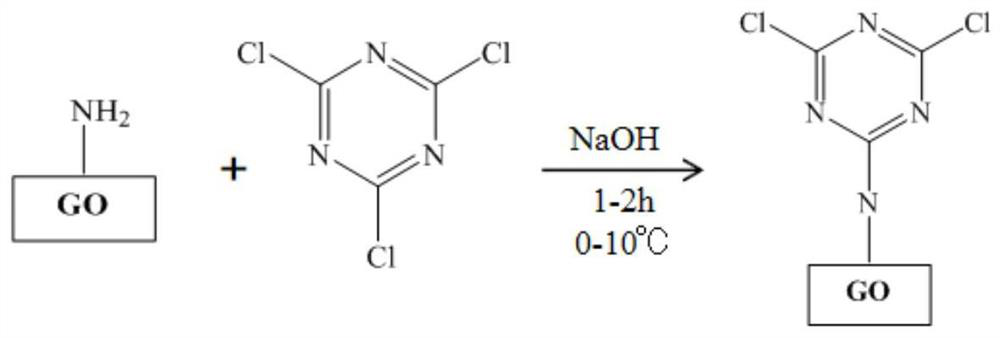

[0035] (2) Preparation of cyanuric chloride grafted graphene oxide: 0.2g ethylenediamine modified graphene oxide was added to 200mL, 35wt% sodium hydroxide solution, mixed evenly, then 0.24g trimeric chloride was added thereto Cyanide was reacted at 10°C for 12 hours, and after the reaction was completed, the reaction product was washed and dried to obtain cyanuric chloride grafted graphene oxide;

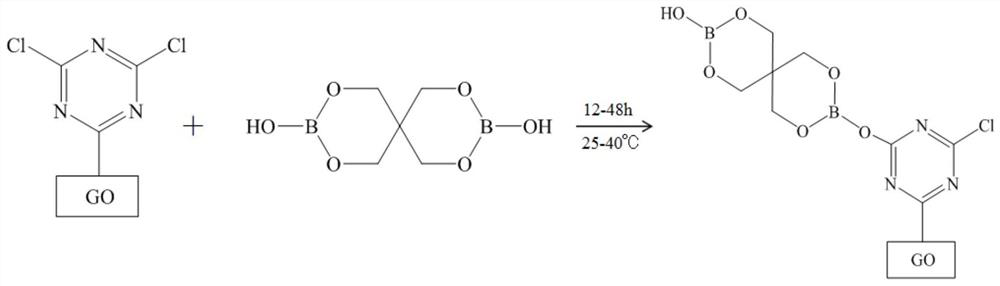

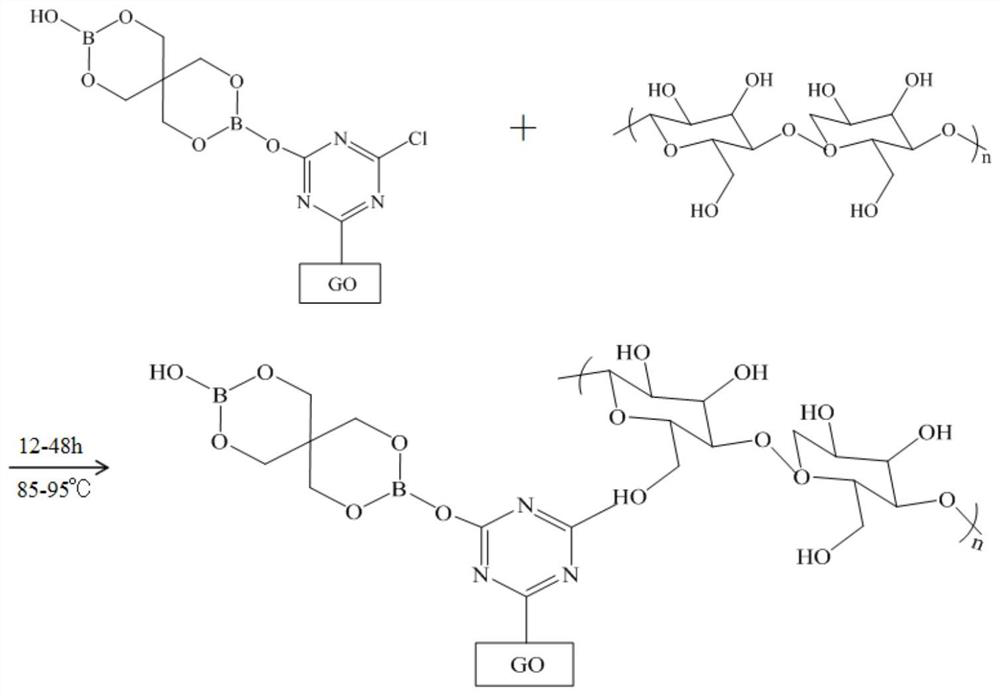

[0036](3) Preparation of penta...

Embodiment 2

[0041] A preparation method for functionalized graphene modified polypropylene wood-plastic board, comprising the steps of:

[0042] (1) Preparation of ethylenediamine-modified graphene oxide: 0.2g graphene oxide was added to 300mL N,N-dimethylformamide, dispersed uniformly, then 300mL ethylenediamine was added thereto, dispersed uniformly, at 55 Stir and reflux at a constant temperature in a warm water bath at ℃ for 6 hours. After the reaction is completed, the reaction product is washed and dried to obtain ethylenediamine-modified graphene oxide;

[0043] (2) Preparation of cyanuric chloride grafted graphene oxide: 0.2g ethylenediamine modified graphene oxide was added to 200mL, 35wt% sodium hydroxide solution, mixed evenly, then 0.25g trimeric chloride was added thereto Cyanide was reacted at 5° C. for 12 hours. After the reaction was completed, the reaction product was washed and dried to obtain cyanuric chloride grafted graphene oxide;

[0044] (3) Preparation of pentaer...

Embodiment 3

[0049] A preparation method for functionalized graphene modified polypropylene wood-plastic board, comprising the steps of:

[0050] (1) Preparation of ethylenediamine-modified graphene oxide: 0.3g graphene oxide was added to 300mL N,N-dimethylformamide, dispersed uniformly, then 300mL ethylenediamine was added thereto, dispersed uniformly, at 60 Stir and reflux at a constant temperature in a warm water bath for 8 hours. After the reaction is completed, wash and dry the reaction product to obtain ethylenediamine-modified graphene oxide;

[0051] (2) Preparation of cyanuric chloride grafted graphene oxide: 0.2g ethylenediamine modified graphene oxide was added to 200mL, 35wt% sodium hydroxide solution, mixed evenly, then 0.28g trimeric chloride was added thereto Cyanide was reacted at 20°C for 16 hours, and after the reaction was completed, the reaction product was washed and dried to obtain cyanuric chloride grafted graphene oxide;

[0052] (3) Preparation of pentaerythritol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com