Dry red wine and production process thereof

A dry red wine and raw wine technology, applied in the field of winemaking, can solve the problems of inability to produce high-quality Cabernet Sauvignon dry red wine, inconsistent quality of Cabernet Sauvignon dry red wine, difficulty in reflecting the regional characteristics of grape raw materials, etc. Grape oxidation, complex aroma, strong stamina effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

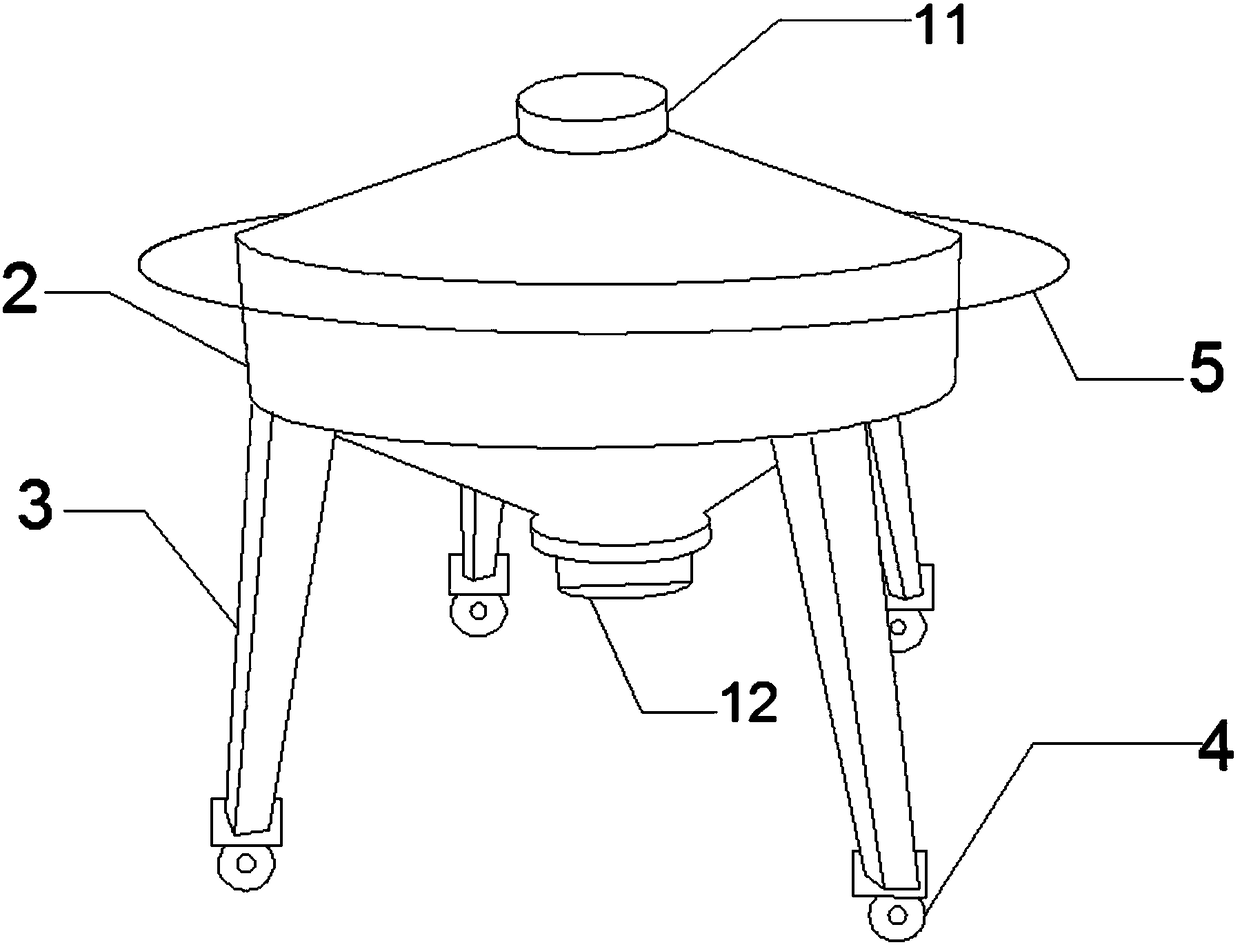

Image

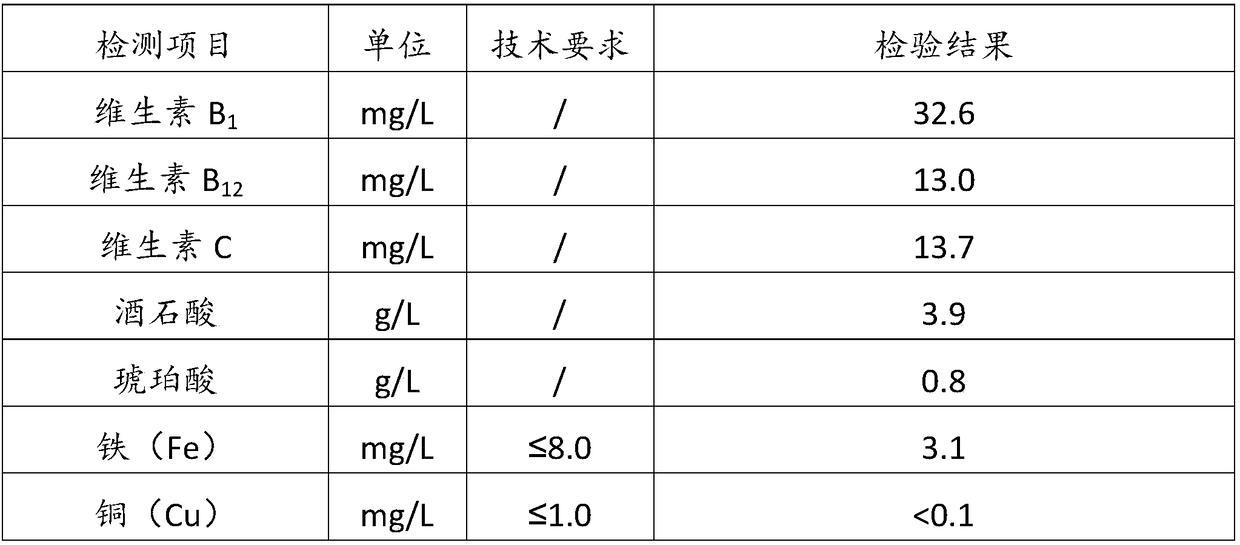

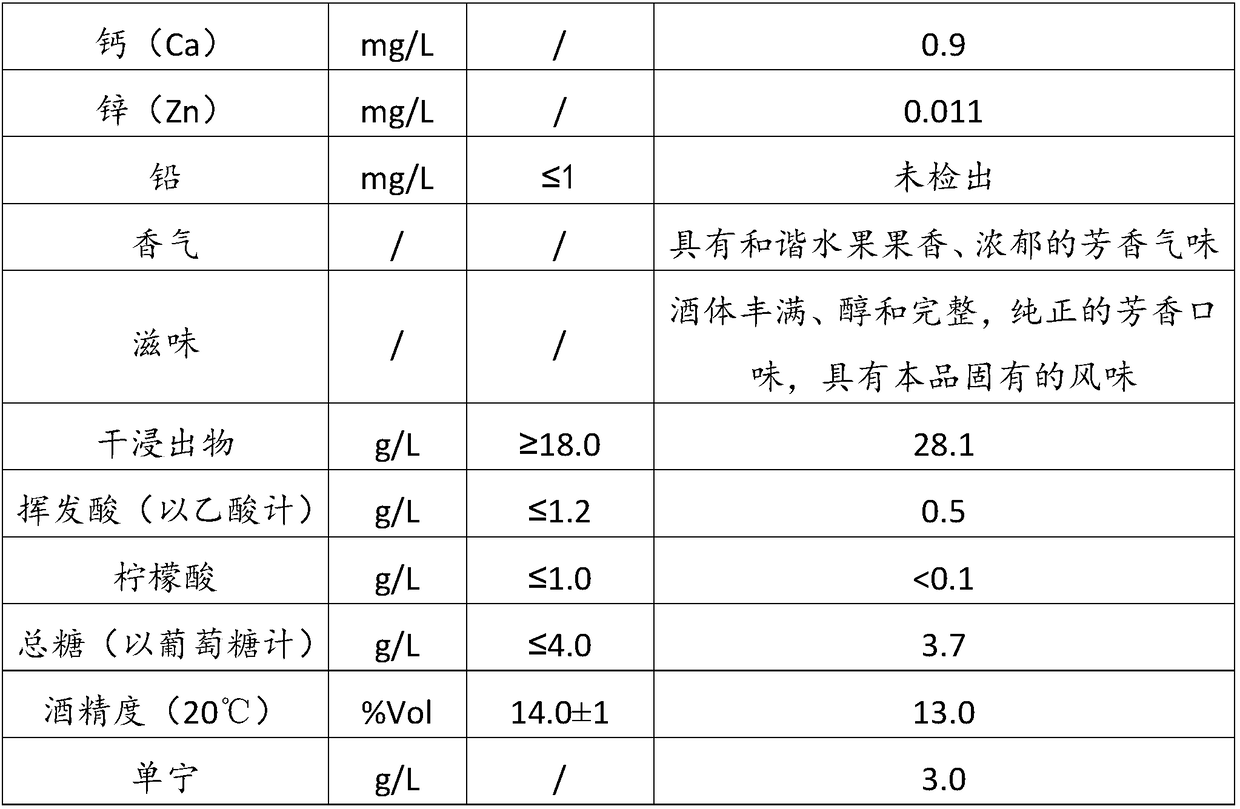

Examples

Embodiment 1

[0046] Present embodiment provides a kind of novel fruit wine dry red wine, and its production technology, the steps are as follows:

[0047] (1) picking and screening healthy, well-maturity and complete fruit ears, stand-by after destemming;

[0048] (2) Clean the fermenter, add dry ice to the fermenter, lower the temperature in the fermenter to 7°C, and send the ears obtained in step (1) into the fermenter by using natural gravity material transmission, Then put potassium metabisulfite and pectinase, keep warm for the first impregnation; then let the fermenter naturally warm up to 16°C, add activated yeast to ferment to form a fermented slurry;

[0049] (3) The fermented slurry obtained in step (2) was dipped for a second time with the skin on for 72 hours, and the temperature of the second skin dipped was 6° C. to form the material to be treated;

[0050] (4) Separating the skin dregs from the material to be treated obtained in step (3) in a self-flowing manner, discarding...

Embodiment 2

[0054] Present embodiment provides a kind of novel fruit wine dry red wine, and its production technology, the steps are as follows:

[0055] (1) picking and screening healthy, well-maturity and complete fruit ears, putting them into a container with dry ice after picking, and removing the stems for later use;

[0056] (2) Clean the fermenter, add dry ice to the fermenter, lower the temperature in the fermenter to 7°C, and send the ears obtained in step (1) into the fermenter by using natural gravity material transmission, Then put potassium metabisulfite and pectinase, keep 7°C for the first immersion for 48 hours; then let the fermenter naturally heat up to 16°C, add activated Saccharomyces cerevisiae for fermentation, and ferment for 10 days at 25°C to form fermented slurry;

[0057] (3) The fermented slurry obtained in step (2) is subjected to a second skin dipping for 66 hours, and the temperature of the second skin dipping is 5° C. to form a material to be treated;

[...

Embodiment 3

[0062] Present embodiment provides a kind of novel fruit wine dry red wine, and its production technology, the steps are as follows:

[0063] (1) picking and screening healthy, well-maturity and complete fruit ears, putting them into a container with dry ice after picking, and removing the stems for later use;

[0064] (2) Clean the fermenter, add dry ice to the fermenter, lower the temperature in the fermenter to 7°C, and send the ears obtained in step (1) into the fermenter by using natural gravity material transmission, Then put potassium metabisulfite and pectinase, keep 7°C for the first immersion for 48 hours; then let the fermenter naturally heat up to 14°C, add activated Saccharomyces cerevisiae for fermentation, add 200g Saccharomyces cerevisiae per ton of grapes 100g of potassium metabisulfite is added to each ton of grapes, 20g of pectinase is added to each ton of grapes, and fermented at 26°C for 10 days to form a fermentation slurry;

[0065] (3) The fermented sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com