Flame-retardant and reinforced integrative natural rubber and preparation method thereof

A natural rubber and fossil technology, which is applied in the field of flame retardant and enhanced integrated natural rubber and its preparation, can solve the problem of incompatibility of flame retardants, easy agglomeration and uneven dispersion, poor interface compatibility between flame retardants and natural rubber materials, etc. problem, to achieve the effect of improving flame retardant efficiency, good thermal stability, and excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

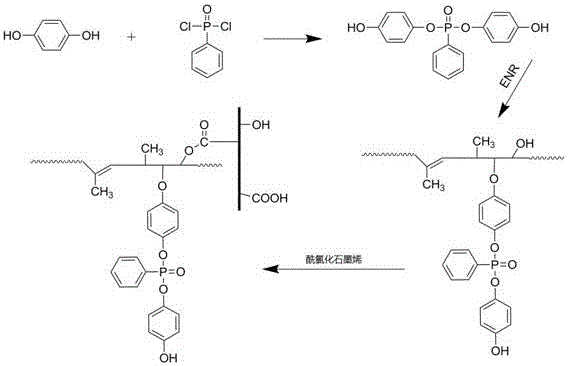

Embodiment 1

[0016] Add hydroquinone and phenylphosphoryl dichloride at a molar ratio of 1:3 to a three-necked flask containing 100ml of dioxane, condense and reflux at 60°C under nitrogen protection for 12 hours with magnetic stirring, and the stirring speed is 850r / min, the product was washed 3 times with ice water, and vacuum-dried for 20 hours to obtain a self-made flame retardant. Add 3 g of graphite powder, 9 g of potassium permanganate, 1.2 g of sodium nitrate and 70 mL of concentrated sulfuric acid into a three-necked flask and mix evenly. Stir and react under ice for 2 hours with a stirring speed of 500 r / min, and then raise the temperature to 20- The reaction was continued for 10 h at 35 °C. Finally, 8 mL of 30% hydrogen peroxide solution was added to the reaction solution. After the reaction was completed, 1 mL of hydrazine hydrate was added to the three-necked flask, and 12 mL of thionyl chloride was added to the reaction system, and the reaction was carried out at 45°C for 5 ...

Embodiment 2

[0018] Add hydroquinone and phenylphosphoryl dichloride at a molar ratio of 1:3 to a three-necked flask containing 100ml of dioxane, condense and reflux at 60°C under nitrogen protection for 12 hours with magnetic stirring, and the stirring speed is 850r / min, the product was washed 3 times with ice water, and vacuum-dried for 20 hours to obtain a self-made flame retardant. Add 3 g of graphite powder, 9 g of potassium permanganate, 1.2 g of sodium nitrate and 70 mL of concentrated sulfuric acid into a three-necked flask and mix evenly. Stir and react under ice for 2 hours with a stirring speed of 500 r / min, and then raise the temperature to 20- The reaction was continued for 10 h at 35 °C. Finally, 8 mL of 30% hydrogen peroxide solution was added to the reaction solution. After the reaction was completed, 1 mL of hydrazine hydrate was added to the three-necked flask, and 12 mL of thionyl chloride was added to the reaction system, and the reaction was carried out at 45°C for 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com