Manufacturing method of low-voltage power cables used in containment of third-generation nuclear power plants

A nuclear power plant containment and low-voltage power technology, applied in the direction of conductor/cable insulation, etc., can solve the safety function requirements of service life, radiation resistance, and flame retardancy, which cannot meet the requirements of third-generation nuclear power, service life, radiation resistance, and flame retardancy There is no big breakthrough in performance, and the effect of improving the ability to inhibit flame spread, excellent electrical performance, and compact cable structure is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

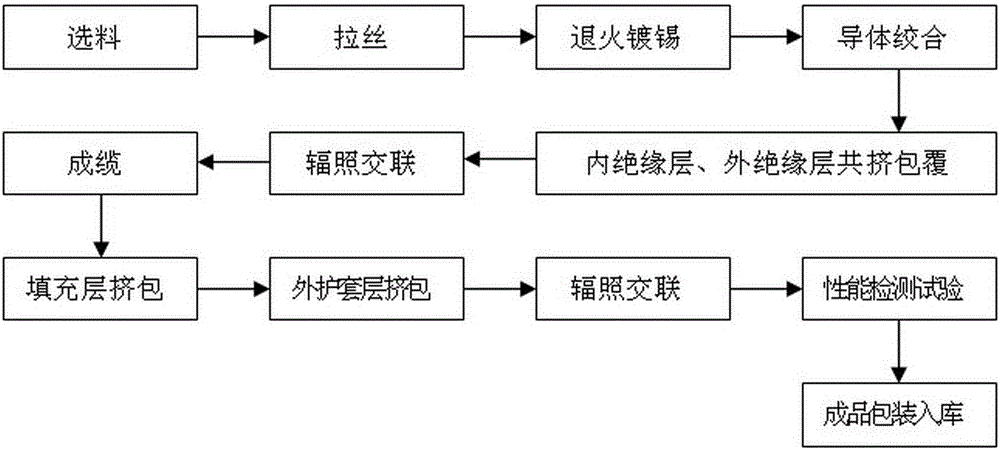

[0025] As a preferred embodiment of the present invention, the manufacturing method of the low-voltage power cable used in the containment of the third-generation nuclear power plant includes the following steps: material selection—wire drawing—annealing and tinning—conductor stranding—inner insulation layer and outer insulation layer co-extrusion Covering—irradiation crosslinking—cable—filling layer extrusion—outer sheath layer extrusion—irradiation crosslinking—performance inspection test—finished product packaging and warehousing.

[0026] Material selection refers to the selection of electrical copper wire blanks for the conductor, and the selection of polymer materials with a thermal life of more than 60 years after long-term heat resistance evaluation for insulation and sheath materials. The insulation and sheath materials of the present invention are selected from polymer materials whose thermal life is greater than 60 years after long-term heat resistance evaluation. Th...

Embodiment 2

[0035]As another preferred embodiment of the present invention, the manufacturing method of the low-voltage power cable used in the containment of the third-generation nuclear power plant includes the following steps: material selection—wire drawing—annealing and tinning—conductor stranding—inner insulating layer and outer insulating layer Extrusion coating—irradiation crosslinking—cable formation—filling layer extrusion—outer sheath layer extrusion—irradiation crosslinking—performance inspection test—finished product packaging and storage.

[0036] Material selection refers to the selection of electrical copper wire blanks for the conductor, and the selection of polymer materials with a thermal life of more than 60 years after long-term heat resistance evaluation for insulation and sheath materials. The insulation and sheath materials of the present invention are selected from polymer materials whose thermal life is greater than 60 years after long-term heat resistance evaluat...

Embodiment 3

[0045] As another preferred embodiment of the present invention, the manufacturing method of the low-voltage power cable used in the containment of the third-generation nuclear power plant includes the following steps: material selection—wire drawing—annealing and tinning—conductor stranding—inner insulating layer and outer insulating layer Extrusion coating—irradiation crosslinking—cable formation—filling layer extrusion—outer sheath layer extrusion—irradiation crosslinking—performance inspection test—finished product packaging and storage.

[0046] Material selection refers to the selection of electrical copper wire blanks for the conductor, and the selection of polymer materials with a thermal life of more than 60 years after long-term heat resistance evaluation for insulation and sheath materials. The insulation and sheath materials of the present invention are selected from polymer materials whose thermal life is greater than 60 years after long-term heat resistance evalua...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com