Waterborne waterproof paint and preparing method thereof

A waterproof coating and water-based technology, which is applied in the field of water-based waterproof coating and its preparation, can solve problems such as inability to effectively achieve publicity functions, uneven quality of waterproof coating products, improper use of waterproof coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

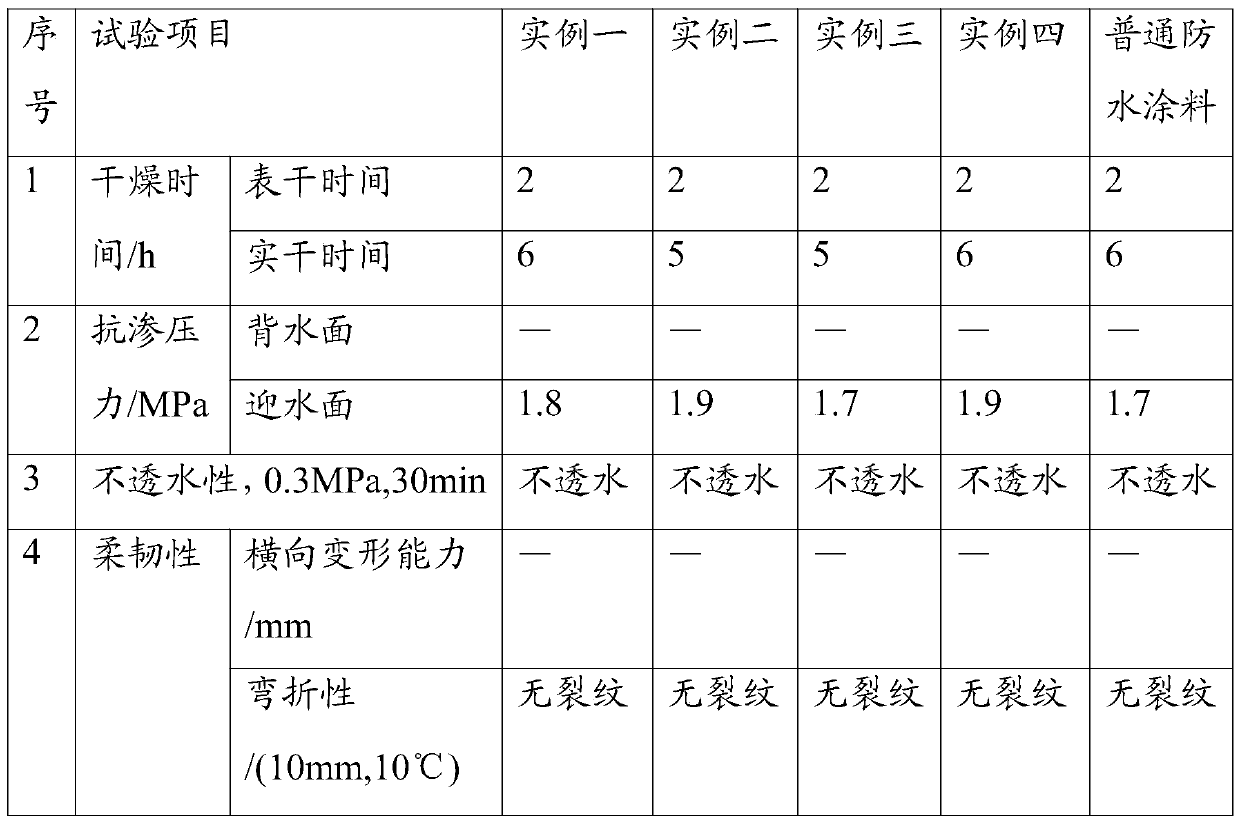

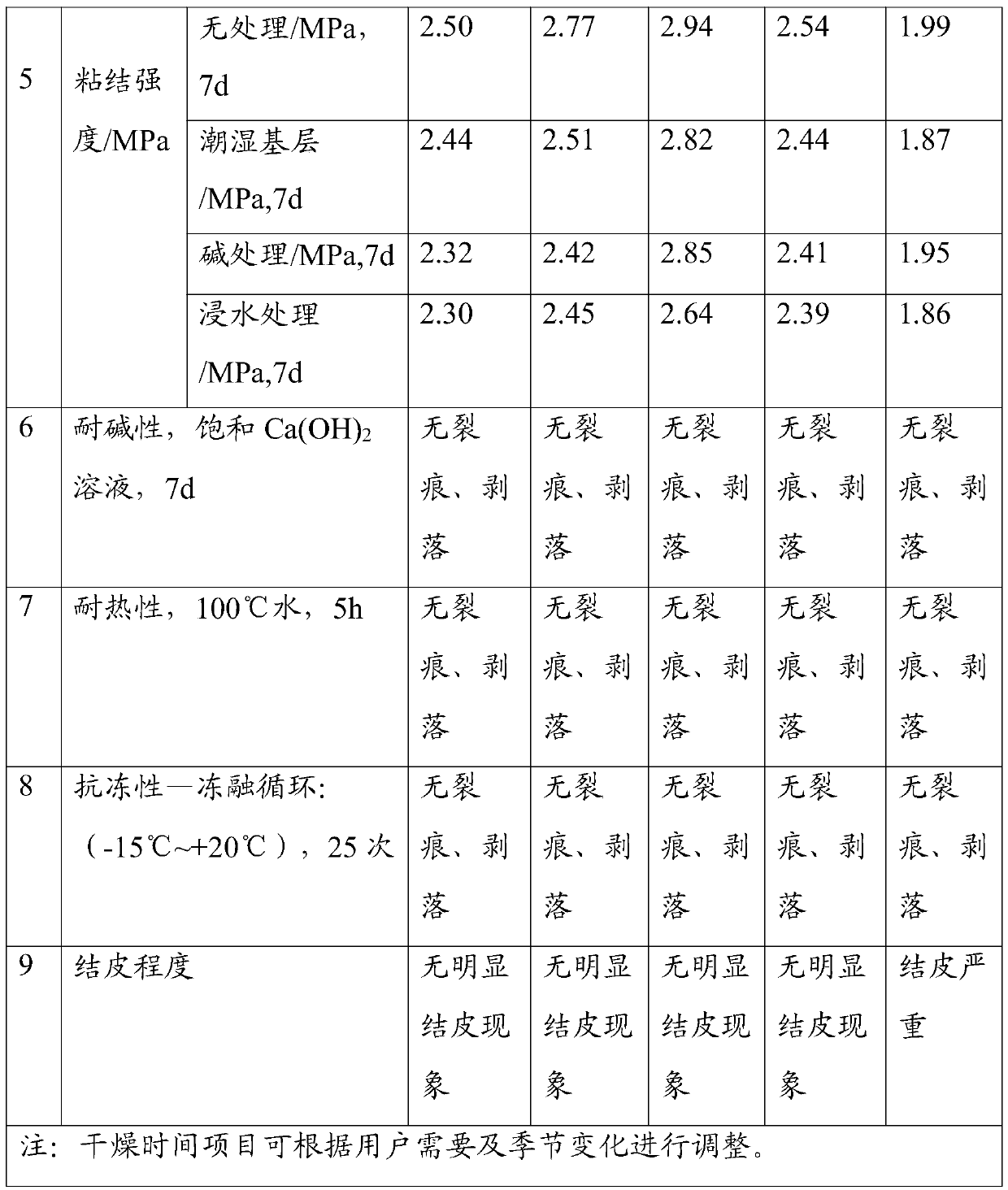

Examples

Embodiment 1

[0034] A water-based waterproof coating provided by the present invention comprises A component and B component, wherein A component is a liquid material, and B component is a powder material, and the weight ratio of the two is A:B=1:1.2; by weight percentage In total, the A component includes: styrene-acrylic emulsion 95%, preservative 0.10%, dispersant 0.20%, defoamer 0.20%, anti-skinning agent 0.5%, water 4%; the B component includes: cement 30%, wollastonite 34%, quartz powder 35.6%, superplasticizer 0.4%.

Embodiment 2

[0036] A water-based waterproof coating provided by the present invention includes A component and B component, wherein A component is a liquid material, and B component is a powder material, and the weight ratio of the two is A:B=1:1.5; by weight percentage In total, the A component includes: styrene-acrylic emulsion 93%, preservative 0.10%, dispersant 0.20%, defoamer 0.20%, anti-skinning agent 0.5%, water 6%; the B component includes: 30% cement, 30% wollastonite, 39.6% quartz powder, 0.4% water reducer.

Embodiment 3

[0038] A water-based waterproof coating provided by the present invention comprises A component and B component, wherein A component is a liquid material, and B component is a powder material, and the weight ratio of the two is A:B=1:1.2; by weight percentage In total, the A component includes: styrene-acrylic emulsion 94%, preservative 0.10%, dispersant 0.10%, defoamer 0.20%, anti-skinning agent 0.6%, water 5%; the B component includes: 35% cement, 25% wollastonite, 39.3% quartz powder, 0.7% water reducer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com