Anti-fogging film, preparation method and application thereof, and application of anti-fogging sticking film

An anti-fog film, base film technology, applied in the direction of film/sheet adhesives, coatings, adhesives, etc., can solve the problems of loss of hydrophilicity, use conditions and service life limitations, surface energy reduction, etc. Improve light transmittance, excellent adhesion, and reduce the effect of contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

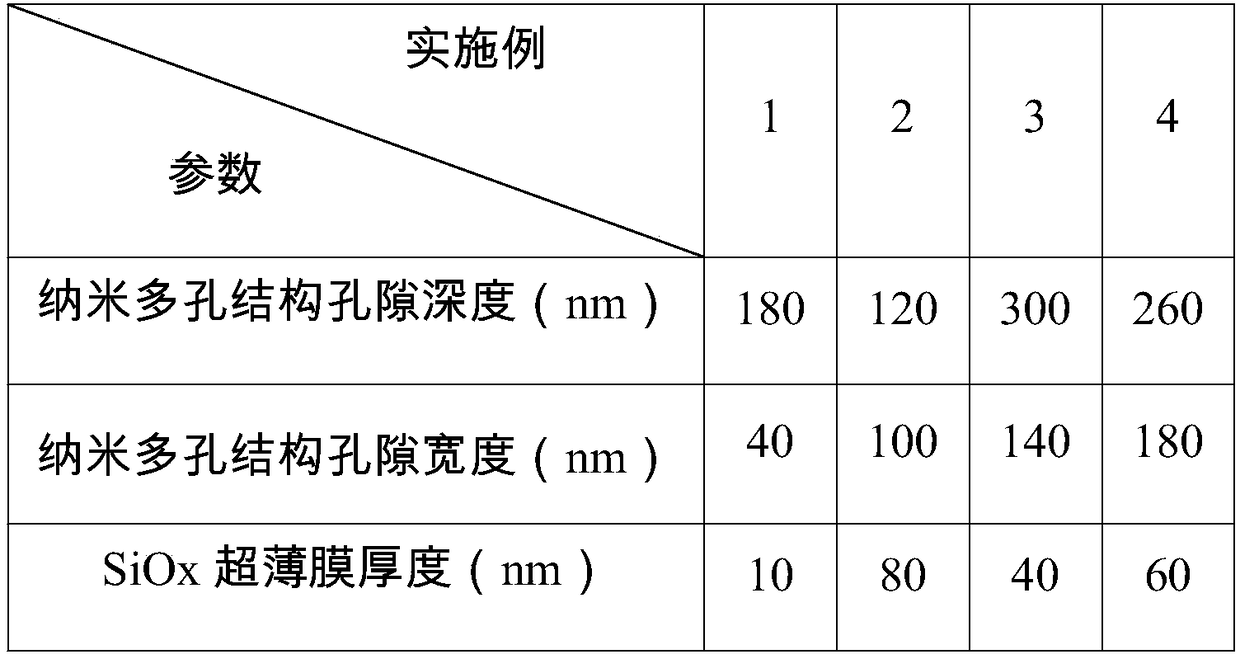

Examples

Embodiment 5-8

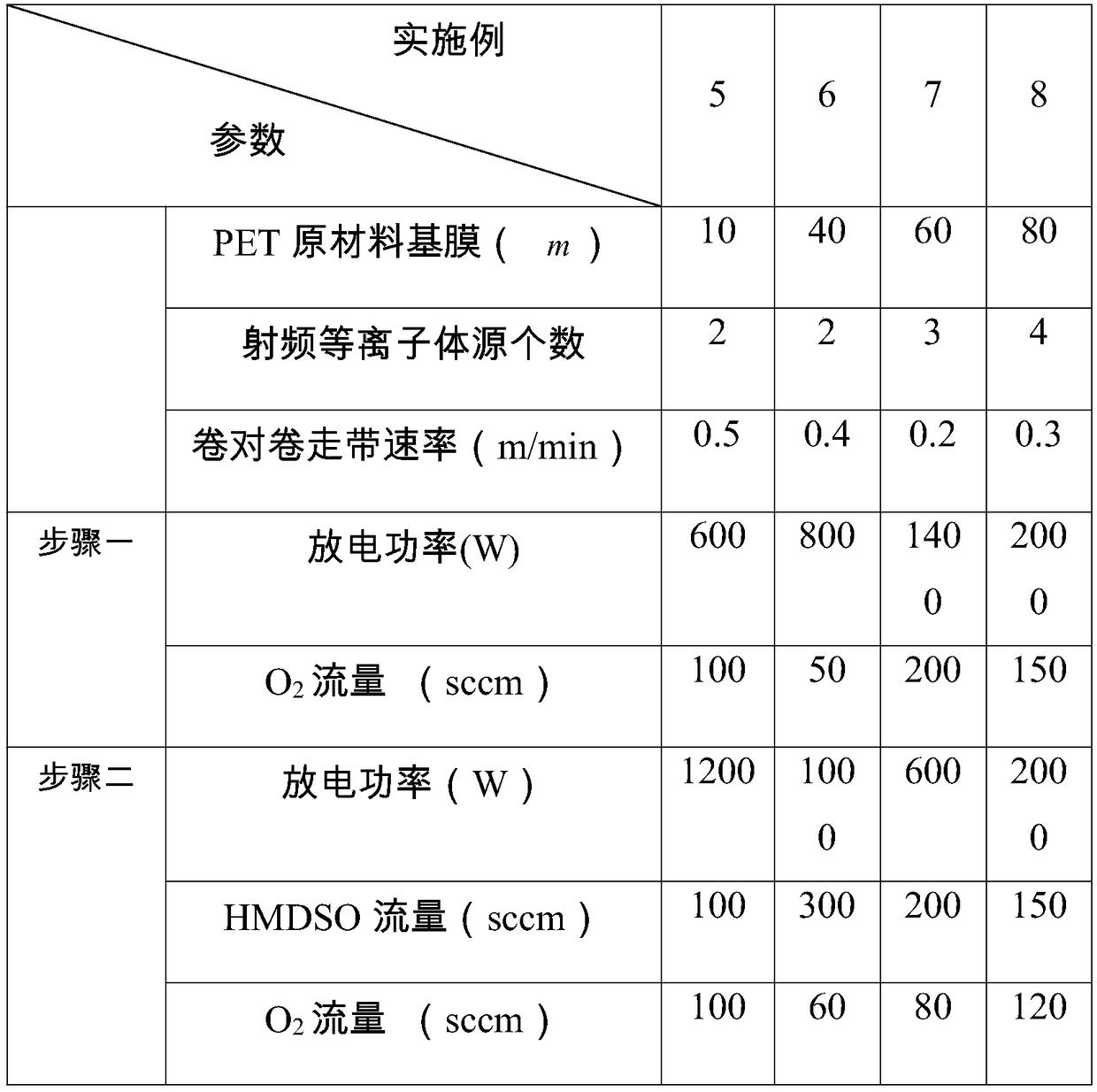

[0034] Embodiment 5-8 has the preparation method of the anti-fog film of nanometer surface structure

[0035] Examples 5-8 are respectively a preparation method of an anti-fog film with a nanometer surface structure, which is completed step by step in the same vacuum chamber using roll-to-roll vacuum coating equipment. The background vacuum of the vacuum chamber is 0.1Pa, and the working vacuum is 10Pa. Two steps in sequence:

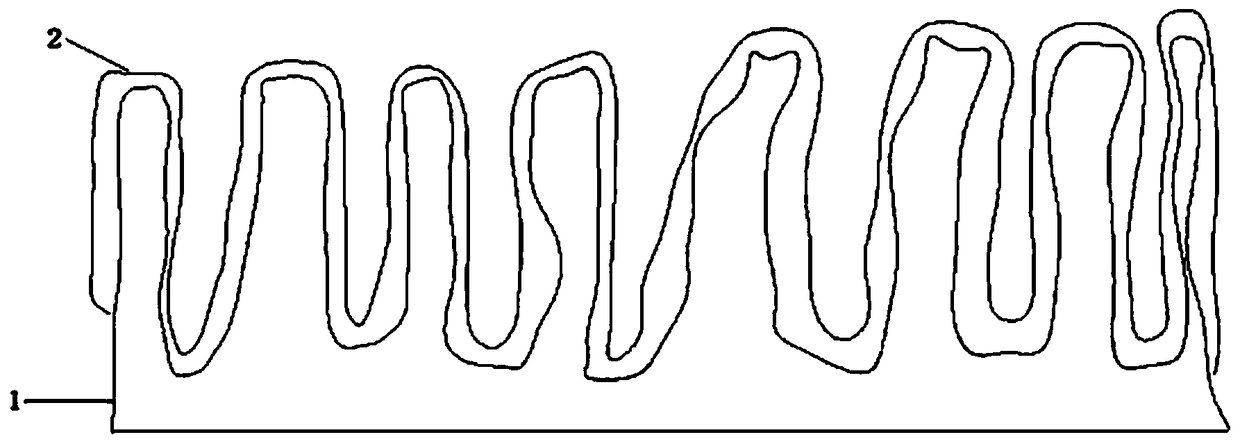

[0036] Step 1, oxygen plasma etching: the roll-to-roll vacuum coating equipment has a tape speed of 0.2-0.5m / min, uses 2-4 radio frequency plasma sources, and the discharge power of each radio frequency plasma source is 600-1200W. The gas is Ar gas, and the ion beam reaction etching gas is O 2 , O 2 The flow rate is 50-200sccm, in Ar, O 2 Reactive ion beam etching is carried out on the PET raw material base film under atmospheric conditions to obtain a PET base film 1 with a nanoporous structure;

[0037] Step 2, using HMDSO monomer as raw material,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com