A kind of epoxy acrylate flame retardant material of zinc-aluminum-tin-containing phosphate intercalation layered hydroxide and preparation method thereof

A layered hydroxide and epoxy acrylate technology, applied in epoxy resin coatings, coatings, fireproof coatings, etc., can solve the problem of insufficient flame retardant and smoke suppression effects of flame retardant hydrotalcite, easy migration of additives and loss of flame retardant Problems such as long-term effect and negative impact on the physical and mechanical properties of materials, to achieve the effect of improving thermal stability and flame retardancy, low cost, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: Preparation of phosphate-intercalated layered hydroxides containing zinc, aluminum and tin

[0036]Weigh respectively 0.025mol of sodium metaaluminate and 0.025mol of sodium hydroxide and dissolve them in 7.2mL of deionized water to form an aqueous solution (A) containing 10% sodium hydroxide and 20% sodium metaaluminate; weigh tin chloride 0.025mol, zinc chloride 0.9375mol, dissolved in 100mL deionized water to make tin chloride and zinc chloride aqueous solution (B); weigh disodium hydrogen phosphate 0.0125mol and dissolve in 100ml deionized water to make sodium salt solution (C).

[0037] At room temperature, pour the (C) solution into a 250mL three-necked round-bottomed flask, and at the same time, slowly drop the (A) and (B) solutions into the (C) solution with a dropping funnel and stir with an electric mixer. , stirred at room temperature for half an hour, adjusted the pH value of the reaction solution to 10-12 with aqueous sodium hydroxide solution, ...

Embodiment 2

[0038] Example 2: Preparation of Epoxy Acrylate Flame Retardant Material Containing Zinc-Aluminum-Tin-Phosphate-Intercalated Layered Hydroxide

[0039] According to the formula in Table 1, prepare a flame retardant coating with a total mass of 10 g. First, weigh 20 parts of acrylamide (AM), disperse and dissolve it in 15 parts of acrylic acid (AA) with a 1000-watt ultrasonic cleaner for 30 minutes, and then dissolve 2.5 to 15 parts ZnCl 2 Dissolve in the above solution by ultrasonication for 10 min, and then add 0 to 10 parts of the zinc-aluminum-tin-containing phosphate intercalation layered hydroxide Zn prepared in Example 1 7.5 Al 2 sn 2 PO 4 -LDH, use an ultrasonic cleaner for about 20 minutes to disperse in the acrylic acid solution dissolved in zinc chloride and acrylamide, and finally add 36 to 61 parts of epoxy acrylate (EA), and then use an ultrasonic cleaner for 30 minutes to disperse it Dissolve until the system is uniform, and then ultrasonically oscillate for ...

Embodiment 3

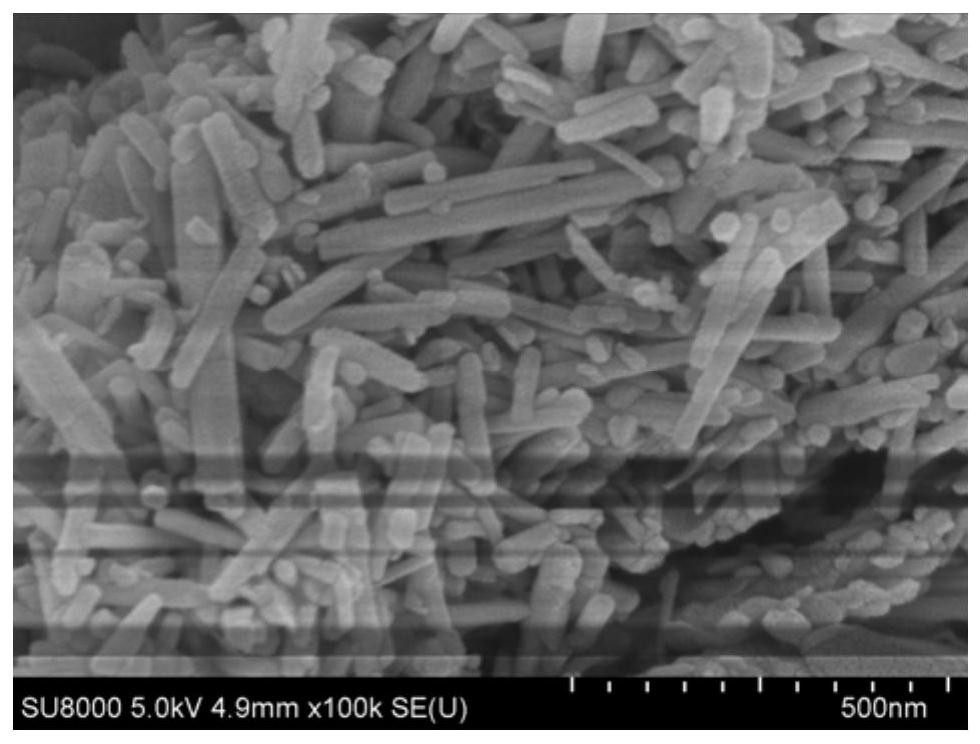

[0043] Example 3: Morphological Analysis of Phosphate Intercalated Layered Hydroxides Containing Zinc, Aluminum and Tin

[0044] figure 1 for Zn 7.5 Al 2 sn 2 PO 4 - SEM image of LDH. Depend on figure 1 It can be seen that it is a nanorod structure with a diameter of about 20nm and a length of about 200nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com