Polylactic acid nano-fiber non-woven fabric surface layer and degradable sanitary towel prepared from same

A technology of polylactic acid fibers and nanofibers, applied in sanitary napkins, biological packaging, layered products, etc., can solve problems such as poor dryness, achieve fast infiltration speed, delicate touch, and prolong the use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

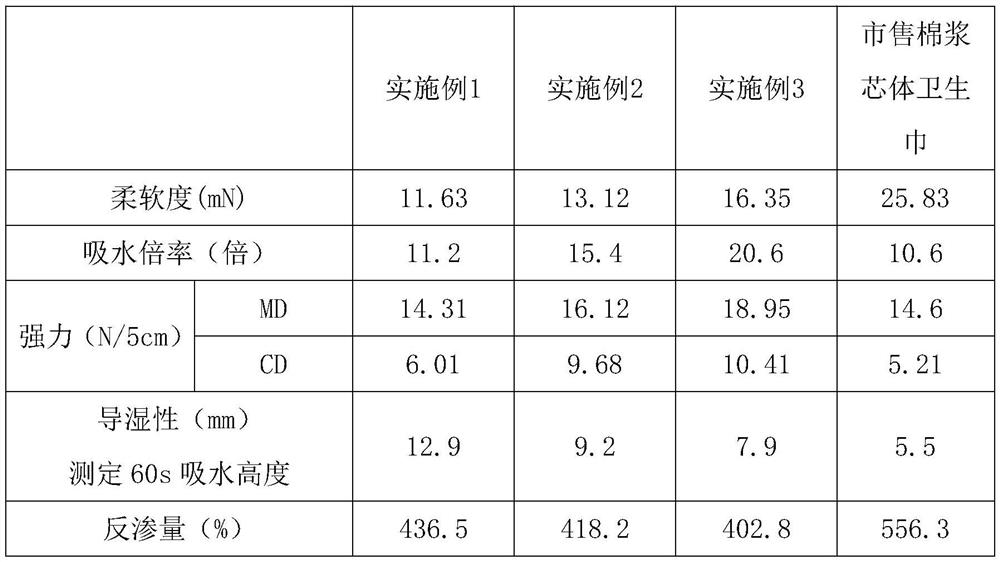

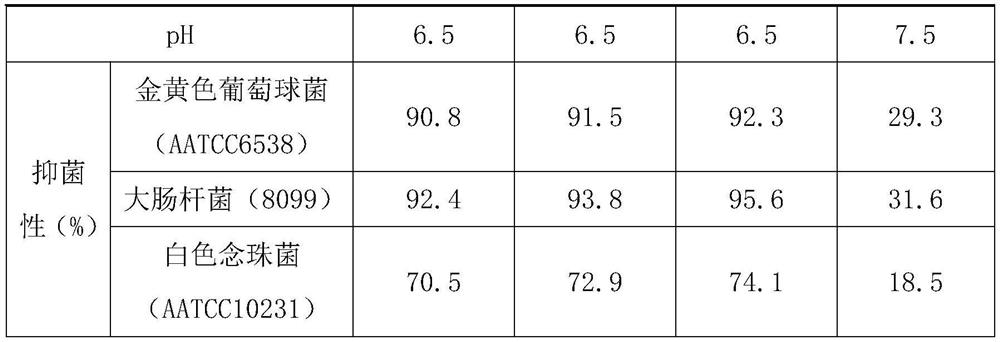

Embodiment 1

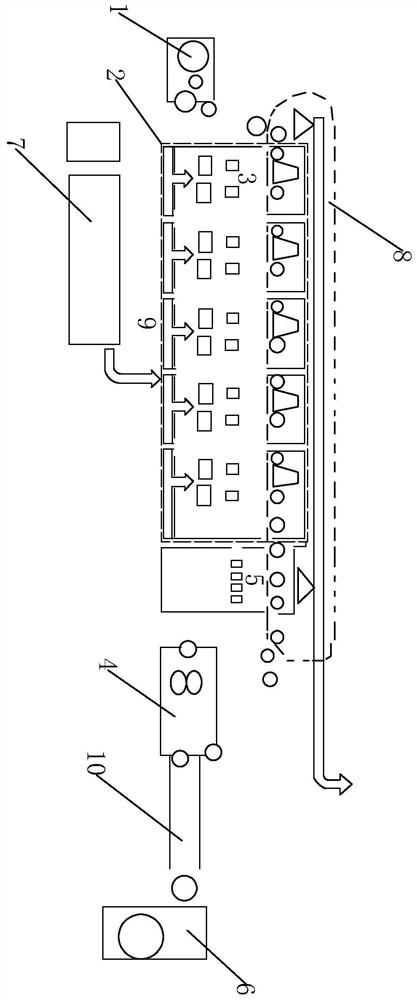

[0042] combine figure 1 , to describe this embodiment in detail. The surface layer of a polylactic acid nanofiber non-woven fabric involved in this embodiment is composed of upper and lower layers of non-woven fabrics, the upper non-woven fabric is a polylactic acid electrospun non-woven fabric layer, and the lower non-woven fabric is a polylactic acid fiber hot air Non-woven fabric layer; the upper layer of non-woven fabric and the lower layer of non-woven fabric are self-adhesively integrated, and then ultrasonically punched to form a surface layer of polylactic acid nanofiber non-woven fabric.

[0043] Preparation of polylactic acid fiber air-through nonwoven fabric with double-layer web

[0044] Coarse denier polylactic acid fiber and polylactic acid bicomponent fiber are used, and the two fibers are weighed and fed in a certain proportion, opened and mixed, carded, cross-laid and drawn to form the lower layer of fiber web. Polylactic acid fiber and polylactic acid two-c...

Embodiment 2

[0067]The surface layer of a polylactic acid nanofiber non-woven fabric involved in this embodiment is composed of upper and lower layers of non-woven fabrics, the upper non-woven fabric is a polylactic acid electrospun non-woven fabric layer, and the lower non-woven fabric is a polylactic acid fiber hot air Non-woven fabric layer; the upper layer of non-woven fabric and the lower layer of non-woven fabric are self-adhesively integrated, and then ultrasonically punched to form a surface layer of polylactic acid nanofiber non-woven fabric.

[0068] Preparation of polylactic acid fiber air-through nonwoven fabric with double-layer web

[0069] Coarse denier polylactic acid fiber and polylactic acid bicomponent fiber are used, and the two fibers are weighed and fed in a certain proportion, opened and mixed, carded, cross-laid and drawn to form the lower layer of fiber web. Polylactic acid fiber and polylactic acid two-component fiber, the two fibers are weighed and fed in a certa...

Embodiment 3

[0091] The surface layer of a polylactic acid nanofiber non-woven fabric involved in this embodiment is composed of upper and lower layers of non-woven fabrics, the upper non-woven fabric is a polylactic acid electrospun non-woven fabric layer, and the lower non-woven fabric is a polylactic acid fiber hot air Non-woven fabric layer; the upper layer of non-woven fabric and the lower layer of non-woven fabric are self-adhesively integrated, and then ultrasonically punched to form a surface layer of polylactic acid nanofiber non-woven fabric.

[0092] Preparation of polylactic acid fiber air-through nonwoven fabric with double-layer web

[0093] Coarse denier polylactic acid fiber and polylactic acid bicomponent fiber are used, and the two fibers are weighed and fed in a certain proportion, opened and mixed, carded, cross-laid and drawn to form the lower layer of fiber web. Polylactic acid fiber and polylactic acid two-component fiber, the two fibers are weighed and fed in a cert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com