Static settling sewage treatment device and method for modification and purification of sludge

A sewage treatment device, sludge technology, applied in the direction of water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

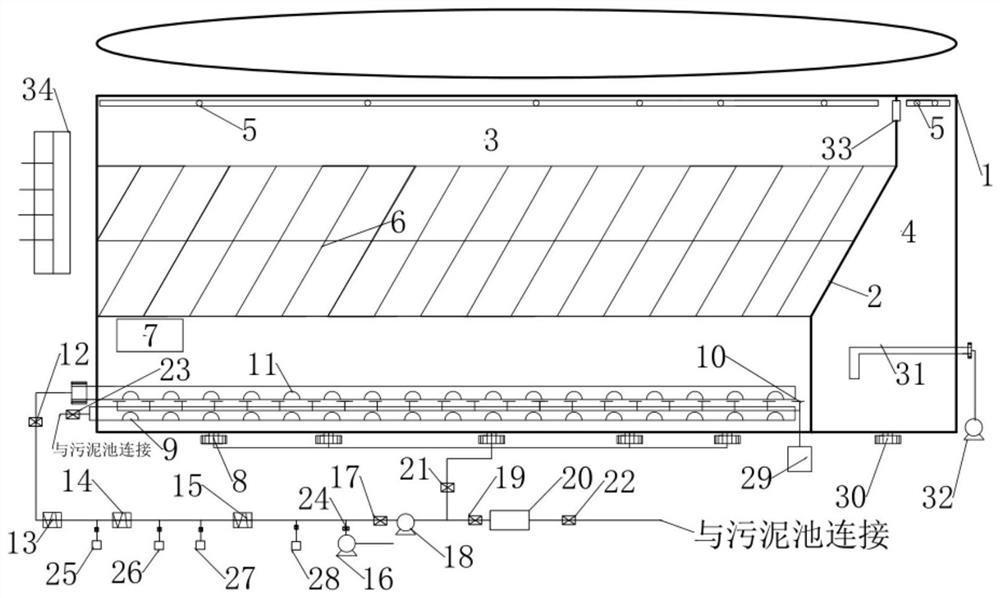

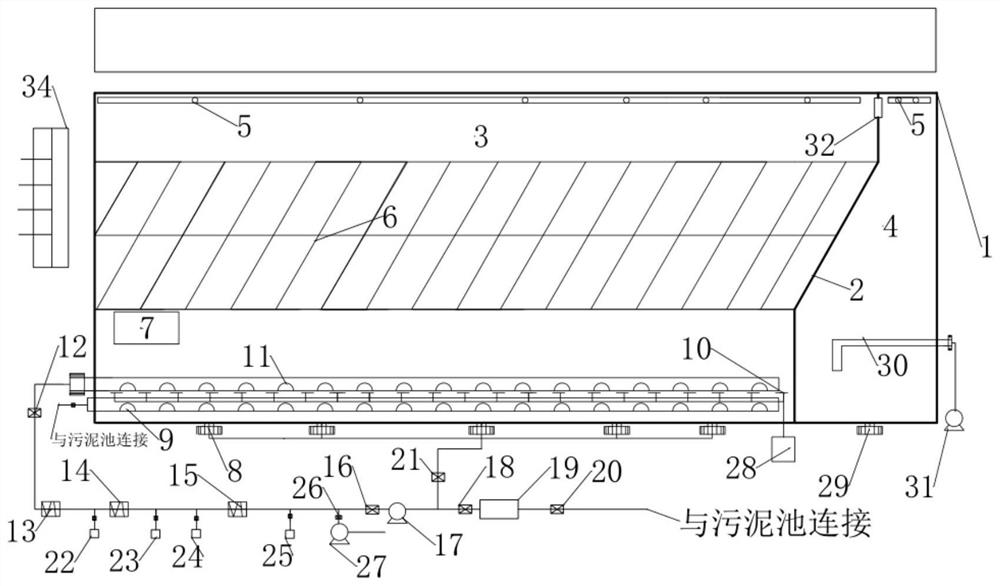

[0097] The nature of sewage water: mineralization degree 56380mg / L, oil content 2640mg / L~3760mg / L, suspended matter content 710mg / L~1130mg / L, sewage treatment capacity 14m 3 / h, considering the fluctuation of sewage, the treatment capacity of sewage static settling device is designed to be 16m 3 / h.

[0098] 1. Manufacture of horizontal square tank for static sewage settling device

[0099] 1. Design of settling chamber 3:

[0100] 1.1. Volume of settling chamber 3

[0101] The treatment capacity of the sewage static sedimentation device is 16m 3 / h, the volume of the settling chamber 3 is calculated according to formula (1), F 1 If the coefficient value is 1.8, then the volume V of the settling chamber 3 沉 28.8m 3 ;

[0102] 1.2. Size design of settling chamber 3

[0103] The height of the settling chamber 3 is 2.5 meters, the width is 2.5 meters, and the length is 4.608 meters. The actual design is 4.7 meters.

[0104] 2. Design of water storage chamber 4

[0105] ...

Embodiment 2

[0148] Sewage incoming water properties: mineralization degree 124810mg / L, oil content 3000mg / L~14000mg / L, suspended matter content 270mg / L~1240mg / L, sewage treatment capacity 21m 3 / h, considering the fluctuation of sewage, the treatment capacity of sewage static settling device is designed to be 25m 3 / h.

[0149] 1. Manufacture of horizontal square tank for static sewage settling device

[0150] 1. Design of settling chamber 3:

[0151] 1.1. Volume of settling chamber 3

[0152] The treatment capacity of the sewage static sedimentation device is 25m 3 / h, the volume of the settling chamber 3 is calculated according to formula (1), F 1 If the coefficient value is 1.75, then the volume V of the settling chamber 3 沉 43.75m 3 ;

[0153] 1.2. Size design of settling chamber 3

[0154] The height of the settling chamber 3 is 2.5 meters, the design width is 2.5 meters, and the length is 7.0 meters. The actual design is 7.0 meters.

[0155] 2. Design of water storage chamb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com