Process method and special device for circulating water treatment of crowfish

A technology of totoaba and special equipment, which is applied in the field of water treatment, can solve the problems of large water consumption, water environment pollution, and low quality of cultured products, and achieve the effects of strong applicability, guaranteed growth environment conditions, and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

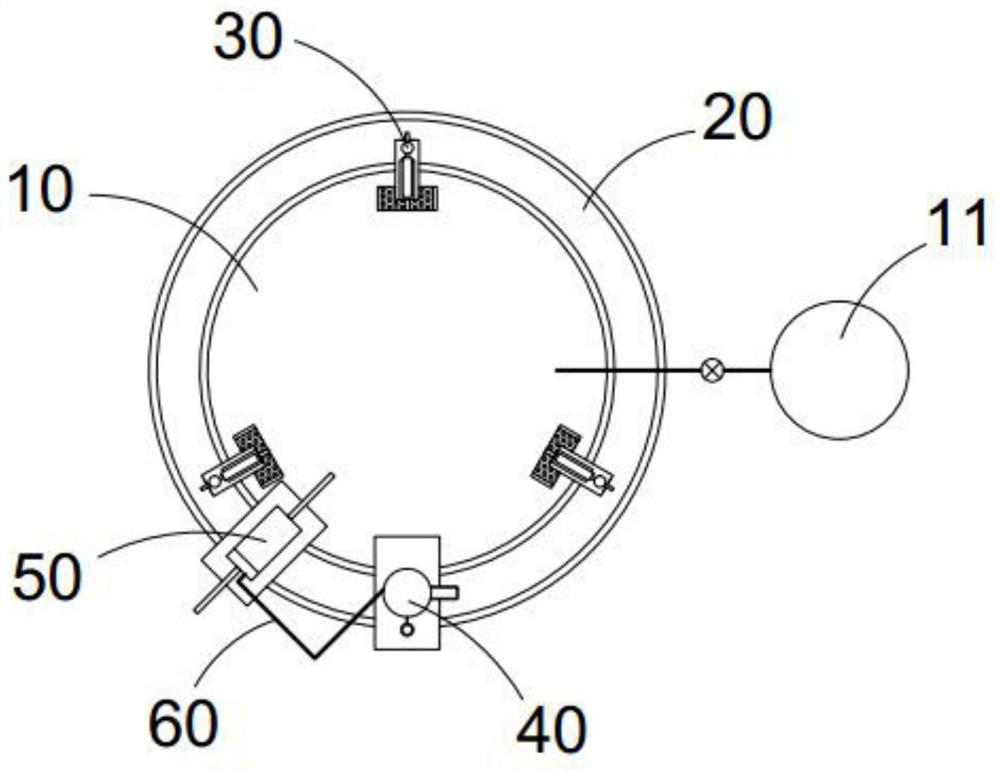

[0045] See attached Figure 1-9 Shown, a kind of totoaba fish circulating water treatment special device, comprises:

[0046] Culture pool 10, the outside of culture pool 10 is surrounded by biological pool 20,

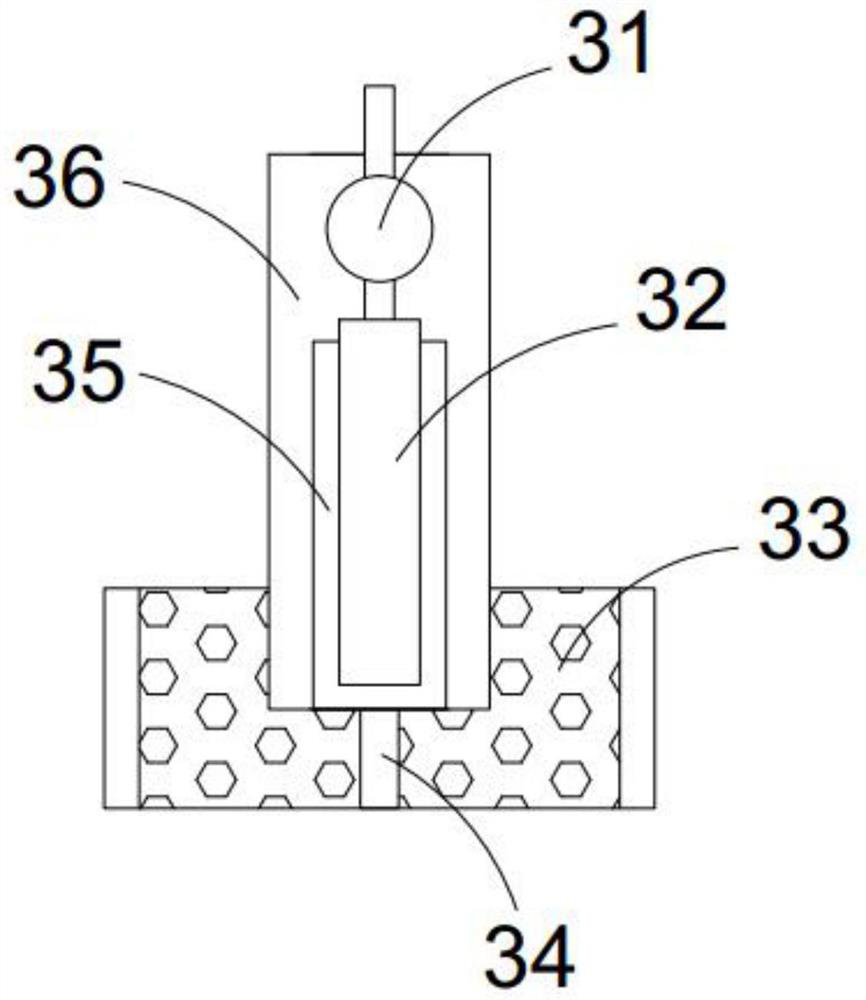

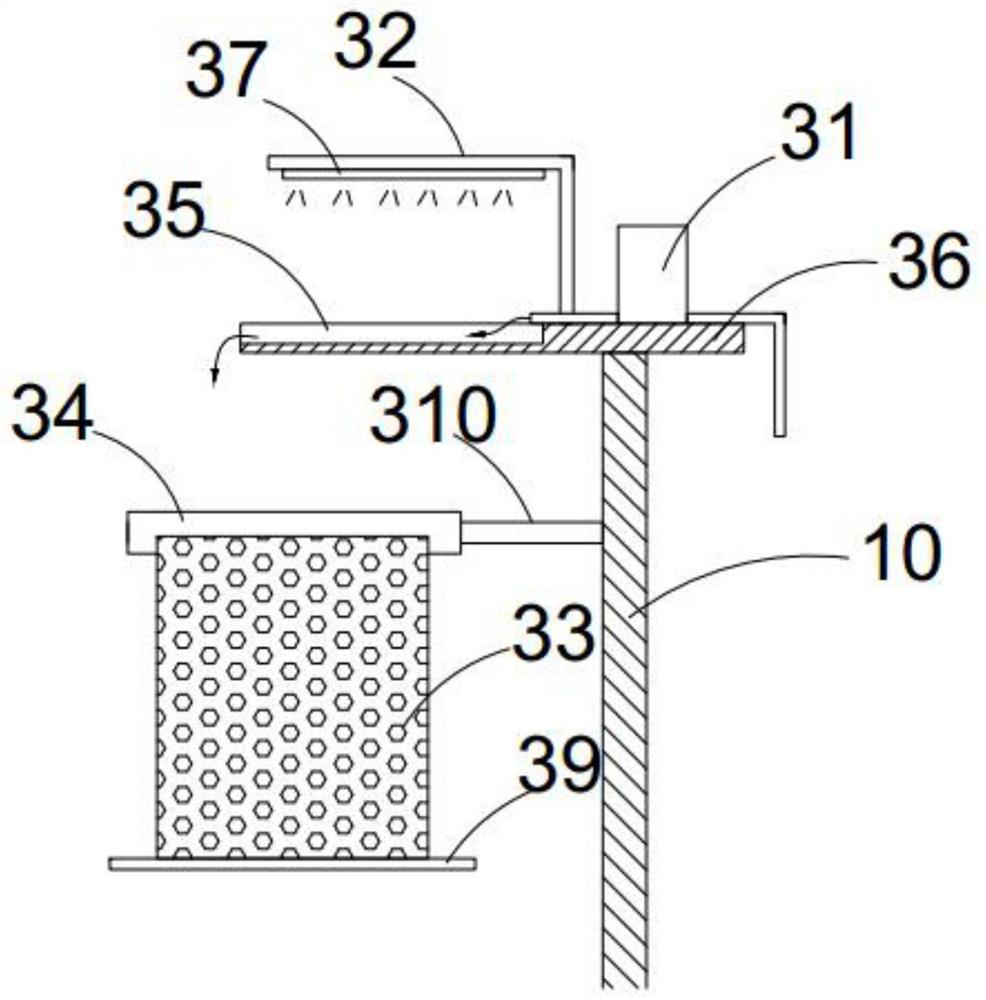

[0047] The sterilization assembly 30 includes a first substrate 36 fixed on the top of the culture pond 10 and placed horizontally. The top of the first substrate 36 is provided with a first pump body 31 , and the water inlet port of the first pump body 31 communicates with the biological pool 20 through a tube. The surface of the first base plate 36 adjacent to the culture pond 10 end is provided with a half-pass diversion half-pass groove 35, and the water outlet end of the first pump body 31 sends the water body into the diversion half-pass groove 35 through the pipe body and makes the water flow along the guide The flow half-through groove 35 enters the culture pond 10,

[0048] Wherein, the inner wall of the culture pond 10 below the first base plate 36 is conn...

Embodiment 2

[0066] A kind of process method of circulating water treatment of totoaba fish:

[0067] - Detect the average concentration of ammonia nitrogen and COD in the aquaculture water, and judge whether it exceeds the set parameters;

[0068] - After judging that the detection parameters of the aquaculture water body exceed the set parameters, the aquaculture water body is extracted from the aquaculture pond 10, filtered through the filter assembly 50, and then processed by the air flotation assembly 40 and discharged into the biological pool 20;

[0069] -The water body in the biological pool 20 is sterilized by the sterilizing component 30 and sent into the breeding pool 10;

[0070] -repeating the above steps to control the detection parameters of the aquaculture water body to be within the range of the set parameter values.

[0071] The present invention controls the filter assembly 50 and the air flotation assembly 40 to purify the aquaculture sewage through continuous detectio...

Embodiment 3

[0073] The further optimization scheme of present embodiment on the basis of embodiment 1 is: see appendix Figure 10 , 11 As shown: one end of the filter barrel 70 is provided with a cleaning assembly 80, and the end of the filter barrel 70 provided with the cleaning assembly 80 is provided with a second support link 72 arranged in a staggered manner, and the second support link 72 and the filter barrel 70 The inner wall of the opening at the end is connected and adjacent to the second support link 72 to form a sewage hole body 73, and the middle part of the second support link 72 arranged in a staggered manner passes through the filter shaft 59, and the filter shaft 59 is connected with a first rotating plate body 82, The plane of the first rotating plate body 82 is arranged perpendicular to the axis of the filter rotating shaft 59, one end of the first rotating plate body 82 is assembled with the filtering rotating shaft 59, and the upper part of the other end is hinged to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com