A kind of waste wood reinforced recycled pvc foam floor and preparation method thereof

A technology of flooring and wood, which is applied in the direction of floors, buildings, building structures, etc., can solve the problems of land expropriation fees, garbage removal and transportation fees, construction funds, environmental impacts, and national ecological impacts, so as to expand the use and realize large-scale Mechanized production, the effect of solving incompatibility problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

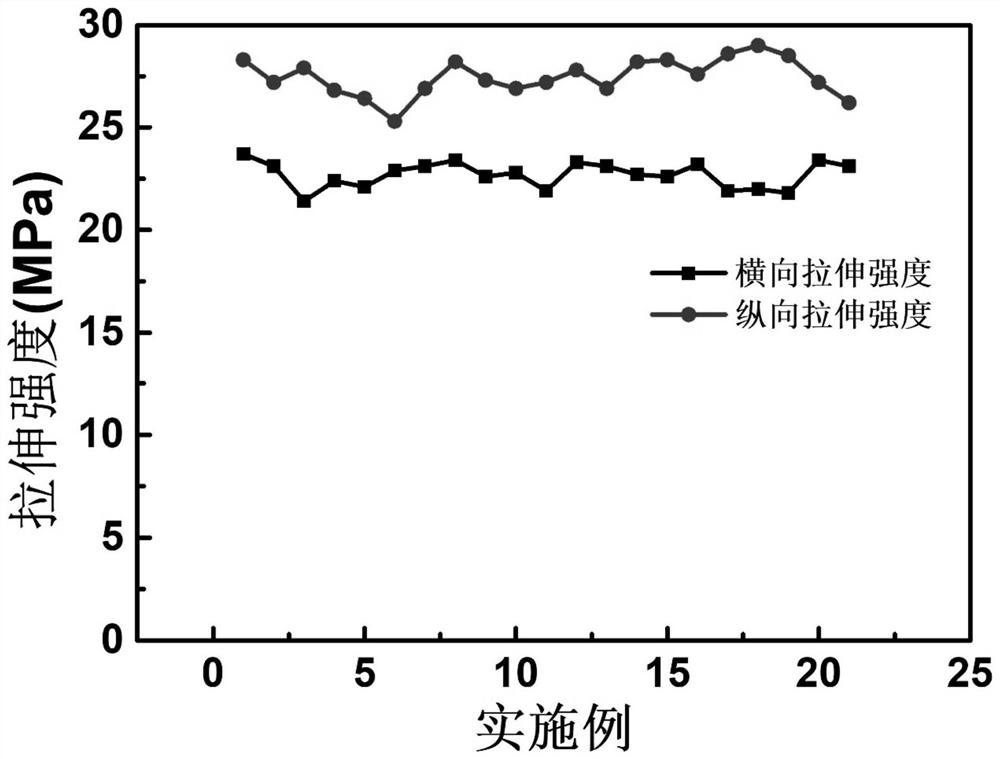

Embodiment 1

[0044] (1) Put the mixed powder of discarded fir, maple and oak into a pulverizer at a ratio of 2:5:2, and grind it into a powdery substance. Grind it into powder, and get PVC powder according to the ratio of 2:3.

[0045] (2) Pour the pulverized charcoal powder on the sieve plate, and use the sieve plate to filter out the charcoal powder with a particle size ranging from 100 to 135 mesh. (3) Place the charcoal powder with the required size in a heating oven at 178° C., and dry it for 3 hours to obtain dry charcoal powder.

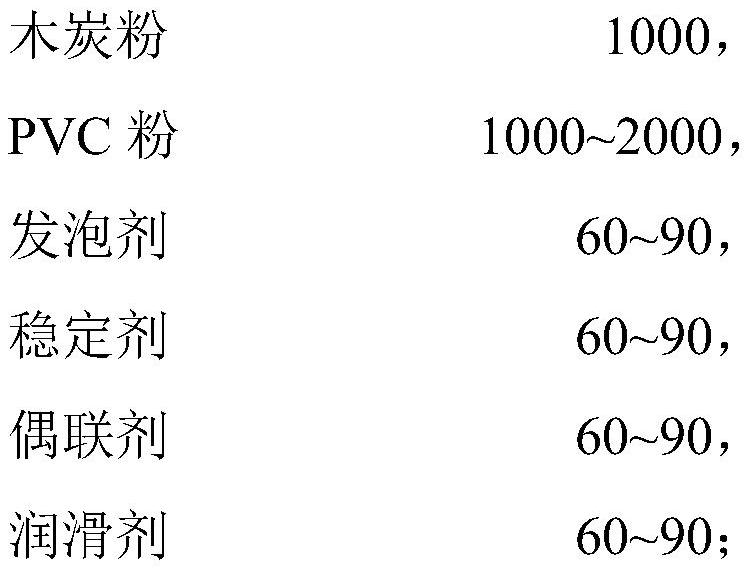

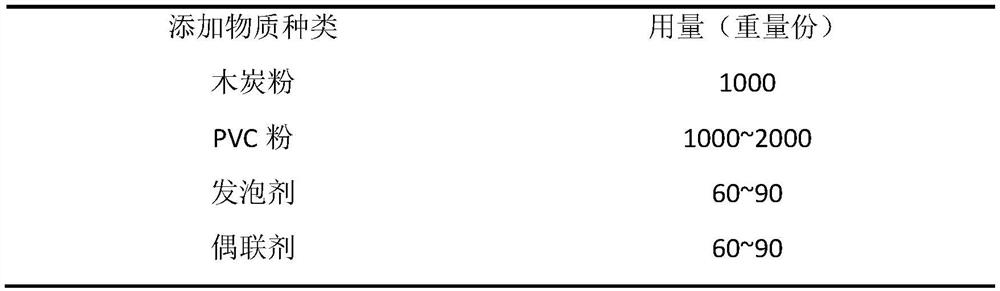

[0046] (4) Take 1000g of dry charcoal powder and put it into a high-speed mixer, set the speed of the mixer to 15-25 r / min, add about 1000g of PVC powder, mix evenly for 45min, then add about 60g of OSBH foaming agent, 60g of Silane coupling agent KH-560 stabilizer, 60g of XT-1 type rare earth stabilizer and 60g of brominated polystyrene.

[0047] (5) Pour the raw material and additive mixture in step (4) into the three-screw extruder, and set the barrel...

Embodiment 2

[0054] Compared with Example 1, change the PVC powder into 1500g in the step (4), and other conditions remain unchanged.

Embodiment 3

[0056] Compared with embodiment 1, change PVC powder into 2000g in the step (4), other conditions remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| autoignition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com