Battery pole group preparation device, battery pole group preparation method and battery pole group

A preparation device and battery electrode technology, which is applied in electrode manufacturing, battery electrodes, electrode rolling/calendering, etc., can solve the problems of lower production efficiency, long warm-up time, softening, etc., so as to improve production efficiency and save production time , The effect of good quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

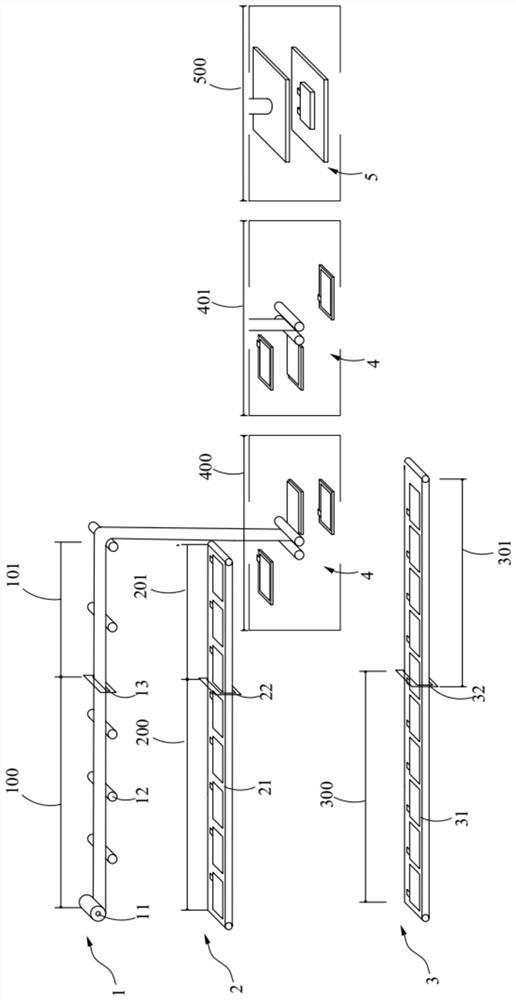

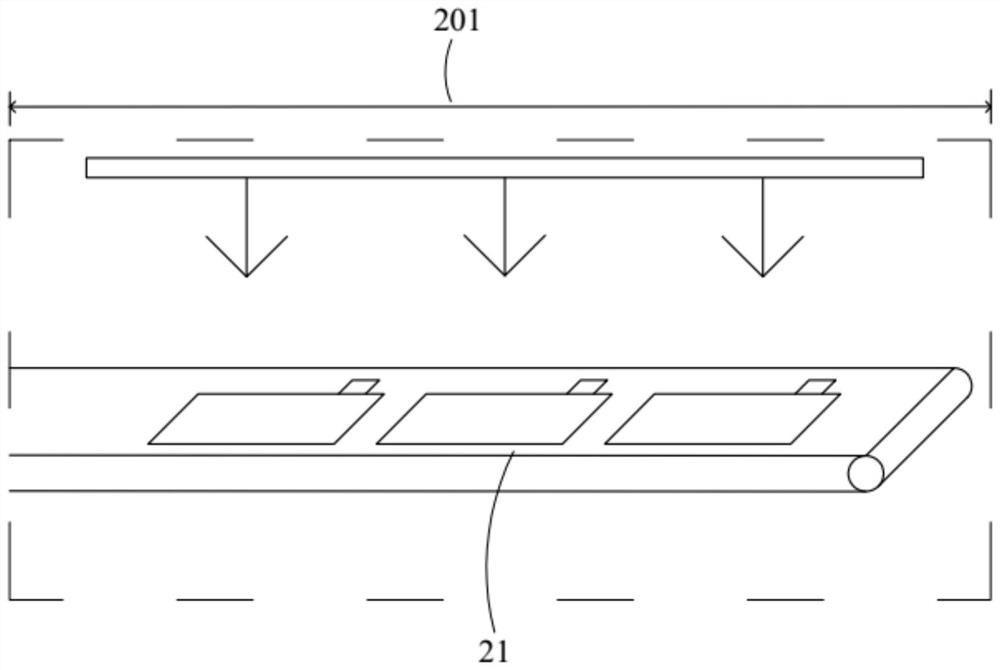

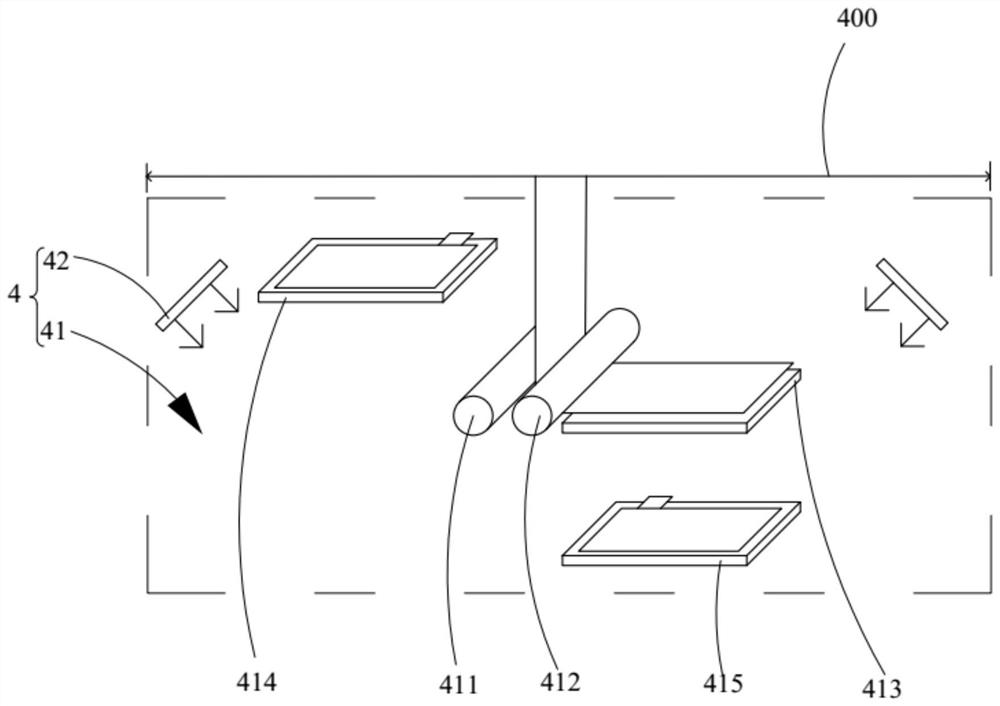

[0094] This embodiment also provides a method for preparing a battery electrode group, which is used to control the above-mentioned device for preparing a battery electrode group. The mechanism heats the diaphragm to complete the diaphragm preheating process; while the second conveying mechanism 2 is conveying the positive electrode sheet, the second heating mechanism is used to heat the positive electrode sheet to complete the positive electrode sheet preheating process; the third conveying mechanism 3 While conveying the positive electrode sheet, use the third heating mechanism to heat the negative electrode sheet to complete the preheating process of the negative electrode sheet; The negative electrode sheet is respectively pressed on both sides of the diaphragm to complete the forming process of the battery pole group.

[0095] The battery pole group preparation method provided in this embodiment uses the first heating mechanism, the second heating mechanism And the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com