Post-dental-extraction automatic pressing-hemostasis device

An automatic and gum technology, applied in dentistry, medical science, surgery, etc., can solve the problems of easy displacement of cotton balls, inability to speak normally, poor hemostatic effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

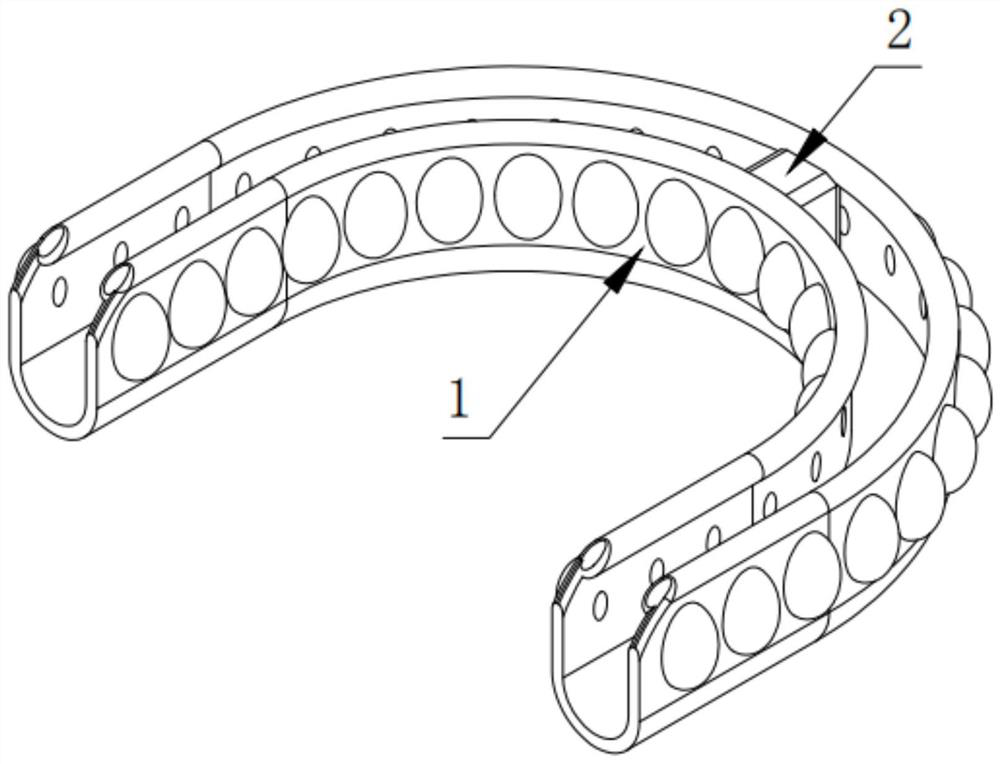

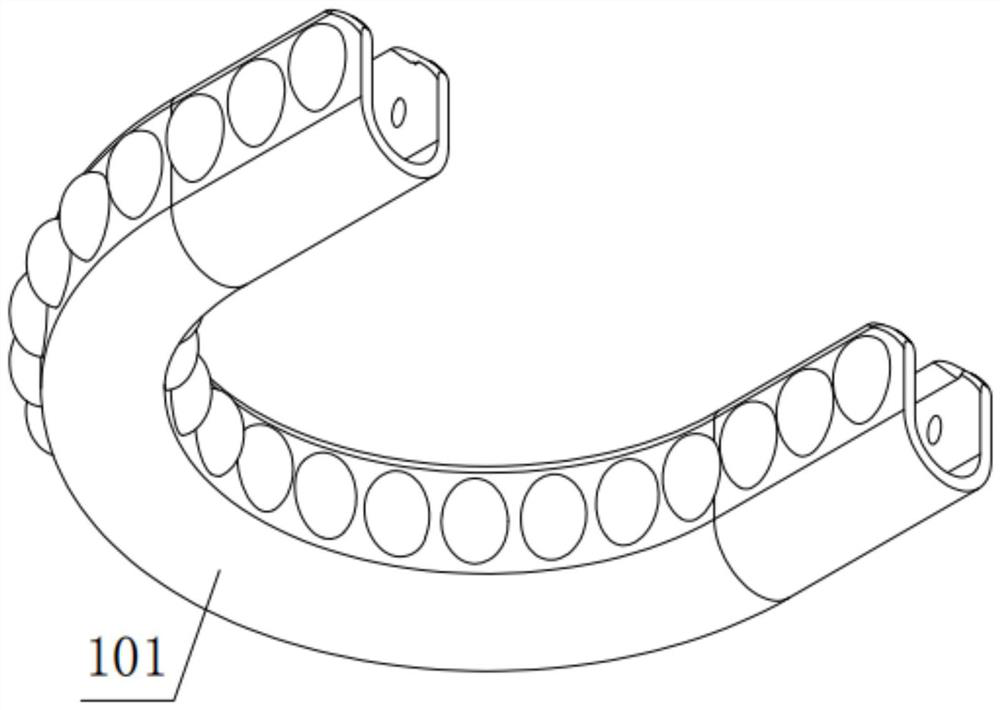

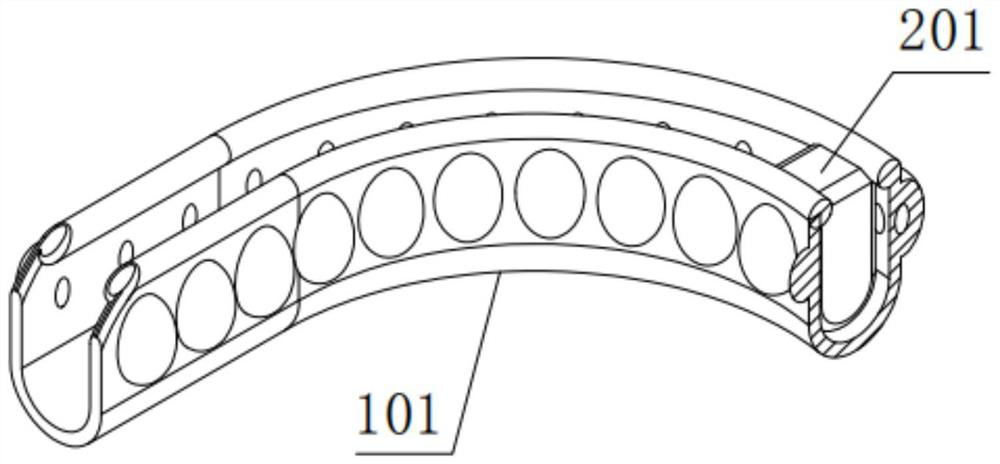

[0042] A device for automatically pressing hemostasis after tooth extraction, such as figure 1 As shown, it includes: a fixing mechanism 1 and a pressing hemostasis mechanism 2 .

[0043] Among them, such as figure 1 As shown, the fixing mechanism 1 is used to fix the whole automatic pressing hemostatic device on the teeth after tooth extraction;

[0044] Among them, such as figure 1 As shown, the pressing hemostatic mechanism 2 is set in cooperation with the fixing mechanism 1, and the pressing hemostatic mechanism 2 is used to press and stop bleeding on the gums after tooth extraction, and absorb the blood flowing out of the gums after tooth extraction.

[0045] The above-mentioned automatic pressure hemostasis device after tooth extraction is composed of a fixing mechanism 1 and a pressure hemostasis mechanism 2, so that the automatic pressure hemostasis device after tooth extraction has a simple structure, is suitable for mass production, and is convenient for widespread...

Embodiment 2

[0062] The difference between this embodiment and Embodiment 1 is that the base 101 is prepared by the following method:

[0063] Take the following raw materials and weigh them by weight: 90 parts of silica gel particles, 15 parts of halogenated butyl rubber, 8 parts of nano-silver powder, 5 parts of silane coupling agent, 25 parts of polypropylene, 3 parts of p-phenylenediamine and diethylthiourea 4 parts;

[0064] S1. Put the weighed silica gel particles, halogenated butyl rubber, nano-silver powder, polypropylene and silane coupling agent into the internal mixer for internal mixing. The temperature of the internal mixer is set to 140°C and the speed is set to 900r / min , the banburying time is 25min, and the banburying material is obtained;

[0065] S2. Add the banburying material prepared in step S1, p-phenylenediamine and diethylthiourea to the mixer for stirring and mixing. The temperature of the mixer is set to 210°C, the speed is set to 900r / min, and the working time ...

Embodiment 3

[0069] The difference between this embodiment and Embodiment 1 is that the base 101 is prepared by the following method:

[0070] Take the following raw materials and weigh them by weight: 100 parts of silica gel particles, 20 parts of halogenated butyl rubber, 10 parts of nano-silver powder, 6 parts of silane coupling agent, 30 parts of polypropylene, 4 parts of p-phenylenediamine and diethylthiourea 5 copies;

[0071] S1. Add the weighed silica gel particles, halogenated butyl rubber, nano-silver powder, polypropylene and silane coupling agent into the internal mixer for internal mixing. The temperature of the internal mixer is set to 160°C, and the speed is set to 1000r / min , the banburying time is 30min, and the banburying material is obtained;

[0072] S2. Add the banburying material prepared in step S1, p-phenylenediamine and diethylthiourea to a mixer for stirring and mixing. The temperature of the mixer is set to 220°C, the speed is set to 1000r / min, and the working t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com