Light high-strength heat-preservation plastering gypsum mortar and preparation method thereof

A plastering gypsum, high-strength technology, applied in the field of building plastering materials, to achieve the effect of increasing compactness, excellent masonry performance, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

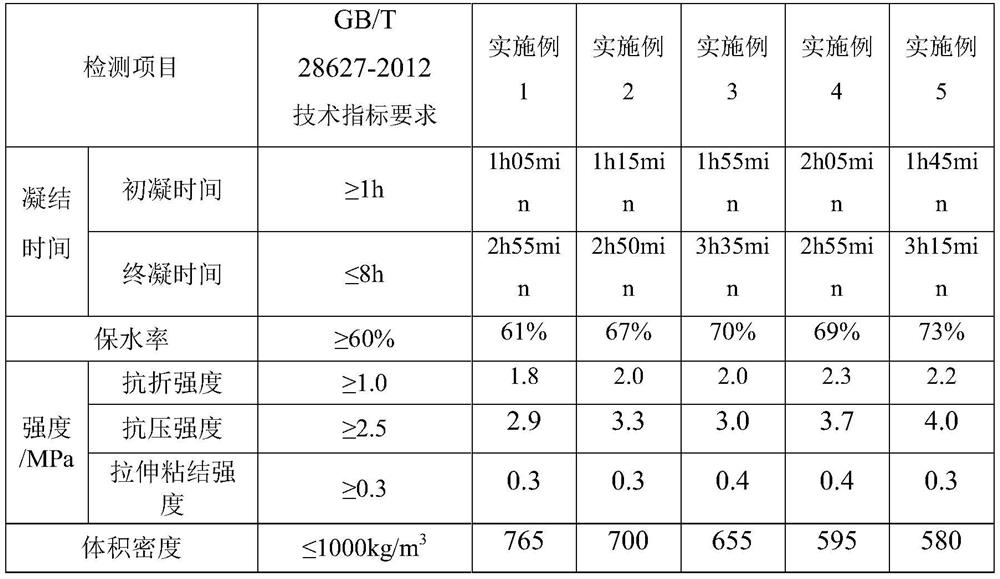

Examples

Embodiment 1

[0021] The light-weight high-strength thermal insulation plastering gypsum mortar of this embodiment includes components and parts by weight of each component: 45 parts of gypsum powder, 5 parts of active magnesium oxide, 1 part of magnesium sulfate, 12 parts of mineral retarder, mineral contact 0.3 parts of variable agent, 3 parts of water-retaining thickener, 4.5 parts of vitrified microbeads, and 40 parts of water.

[0022] The mineral retarder in this example is ultrafine mineral powder, ultrafine fly ash, ultrafine silica fume 1:1:0.1, the same as the following examples.

[0023] The preparation method of the mortar comprises the following steps: the preparation method of the light-weight high-strength thermal insulation plastering gypsum mortar is as follows: 1) taking the weighed gypsum powder, active magnesium oxide, mineral retarder, mineral thixotropic agent, and water-retaining thickener , Vitrified microbeads are mixed and stirred evenly; 2) The magnesium sulfate t...

Embodiment 2

[0026] The light-weight high-strength thermal insulation plastering gypsum mortar of this embodiment includes components and parts by weight of each component: 55 parts of gypsum powder, 6 parts of active magnesium oxide, 1.1 parts of magnesium sulfate, 15.25 parts of mineral retarder, mineral contact 0.4 parts of variable agent, 3% to 5.5 parts of water-retaining thickener, 7 parts of vitrified microbeads, and 50 parts of water.

[0027] The preparation method of the mortar comprises the following steps: the preparation method of the light-weight high-strength thermal insulation plastering gypsum mortar is as follows: 1) taking the weighed gypsum powder, active magnesium oxide, mineral retarder, mineral thixotropic agent, and water-retaining thickener , Vitrified microbeads are mixed and stirred evenly; 2) The magnesium sulfate that weighs is mixed with water and stirred evenly; 3) The mixture obtained in step 2 is added to the mixture obtained in step 1, and after adding whil...

Embodiment 3

[0029] The light-weight high-strength thermal insulation plastering gypsum mortar of this embodiment comprises components and parts by weight of each component: 65 parts of gypsum powder, 7 parts of active magnesium oxide, 1.2 parts of magnesium sulfate, 23 parts of mineral retarder, mineral contact 0.6 parts of variable agent, 4 parts of water-retaining thickener, 10 parts of vitrified microbeads, and 60 parts of water.

[0030] The preparation method of the mortar comprises the following steps: the preparation method of the light-weight high-strength thermal insulation plastering gypsum mortar is as follows: 1) taking the weighed gypsum powder, active magnesium oxide, mineral retarder, mineral thixotropic agent, and water-retaining thickener , Vitrified microbeads are mixed and stirred evenly; 2) The magnesium sulfate that weighs is mixed with water and stirred evenly; 3) The mixture obtained in step 2 is added to the mixture obtained in step 1, and after adding while stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com