Reaction system and method for preparing ethylene glycol by chloroethanol method

A reaction system and technology of chloroethanol, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of increasing the difficulty and cost of preparation, high temperature requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

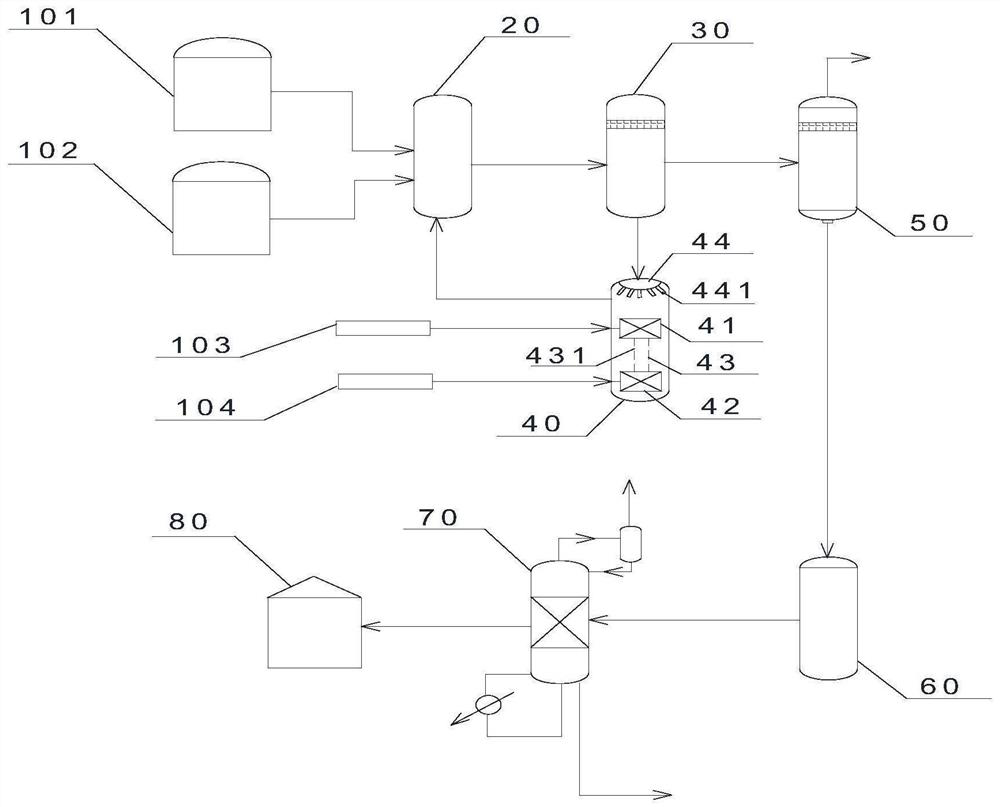

[0054] refer to figure 1 As shown, the reaction system for preparing ethylene glycol from the chloroethanol provided by the embodiment of the present invention mainly includes a sodium bicarbonate storage tank 101, a chloroethanol storage tank 102, a main material reactor 20, a crystallizer 30, and a recycling reactor 40. Carbon dioxide inlet pipeline 103, ammonia gas inlet pipeline 104, distillation tower 50, filter 60, rectification tower 70 and ethylene glycol storage tank 80. Sodium bicarbonate storage tank 101 and chloroethanol storage tank 102 are connected with main material reactor 20 in order to deliver raw material sodium bicarbonate and chloroethanol to main material reactor 20, sodium bicarbonate and chloroethanol take place in main material reactor 20 The reaction produces ethylene glycol and by-product sodium chloride, and the reaction temperature is 100°C. The ethylene glycol and sodium chloride produced by the reaction are transported to the crystallizer 30 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com