Patents

Literature

43 results about "Chloranolol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Expanded transparent fire-retardant paint

InactiveCN103627291AGood thermal insulation performanceImprove the decorative effectFireproof paintsO-Phosphoric AcidPentaerythritol

The invention relates to an expanded transparent fire-retardant paint which is composed of the following components in parts by mass: 50-55 parts of formaldehyde, 20-30 parts of urea, 15-25 parts of dicyandiamide, 30-35 parts of isopropanol, 15-25 parts of titanium white, 5-10 parts of formic acid, 1-5 parts of flame retardant, 5-10 parts of pentaerythritol, 2-5 parts of chlorinated paraffin, 4-8 parts of sodium hydroxide, 1-5 parts of phosphoric acid, 30-40 parts of phosphorus oxychloride, 25-30 parts of chloroethanol and 10-15 parts of distilled water. The fire-retardant time of the coated film of the product is 140-150 minutes when the thickness is 0.5-1.5 mm; the product has better expanded heat-insulating property at high temperature, and the height of the expansion layer is up to 2-2.5cm; the product is transparent, has the advantages of low toxicity and favorable decorative property, and is easy for construction; and the product has excellent fire retardancy (reaching Level 1 in national standard), and can be widely produced and continuously substitute the existing material.

Owner:江苏博思源防火材料科技有限公司

Hydrogel containing cyclodextrin and polyethylene glycol block polypeptide molecular brush as well as preparation method and application of hydrogel

InactiveCN104592511AEasy to prepareEasy to controlAerosol deliveryOintment deliveryBiocompatibility TestingEther

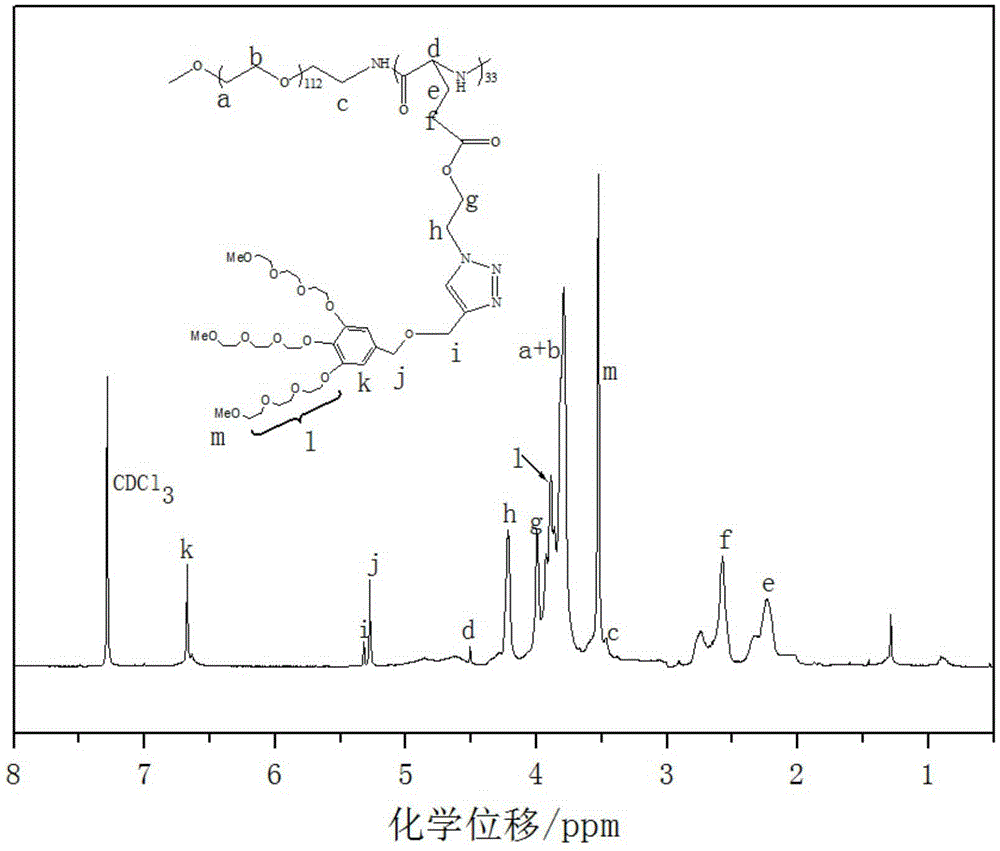

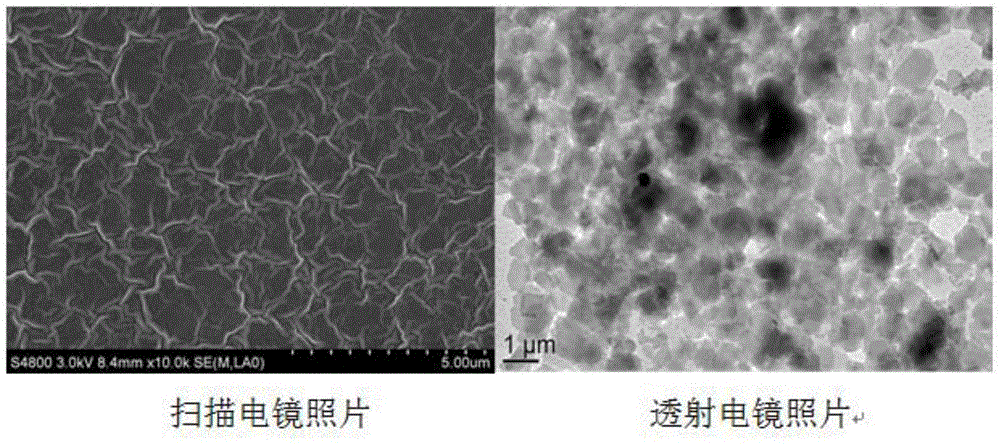

The invention discloses a polyethylene glycol block polypeptide molecular brush. The polyethylene glycol block polypeptide molecular brush has a structure as shown in a formula (1) in the specification, and comprises a main chain and a side chain, wherein the main chain is a two-block polymer composed of polyethylene glycol and polypeptide; the side chain is an alkoxy ether dendrimer. The preparation method comprises the following steps: preparing gamma-chloroethyl-L-glutamate from chlorohydrin and L-glutamic acid, and initiating the ring opening polymerization of alpha-amino acid-N-carboxyanhydride by use of amino polyethylene glycol monomethyl ether to obtain polyethylene glycol-b-poly(gamma-chloroethyl-L-glutamate; grafting the alkoxy ether dendrimer to the polypeptide chain by virtue of azidation and click reaction, thereby preparing the polyethylene glycol block polypeptide molecular brush. The invention also discloses a hydrogel containing alpha-cyclodextrin and the polyethylene glycol block polypeptide molecular brush. The hydrogel is prepared by mixing and stirring the molecular brush and the alpha-cyclodextrin in water and then performing ultrasonic and standing treatment. The hydrogel has unique structure andmorphology and excellent biocompatibility, and has wide application prospect in the fields of functional materials, cell culture medias, medicine carrier and the like.

Owner:EAST CHINA NORMAL UNIVERSITY +1

Special florescence prolonging medicament for flower of rape flower

InactiveCN104839215AProlong flowering periodToxic reductionPlant growth regulatorsBiocideBiotechnologyThiourea

The invention discloses a special florescence prolonging medicament for a flower of a rape flower. The special florescence prolonging medicament for the flower of the rape flower is prepared from the following raw materials in parts by weight: 5 to 10 parts of 6-benzylaminopurine, 6 to 12 parts of naphthylacetic acid, 4 to 8 parts of 2, 4-dichlorphenoxyacetic acid, 2 to 4 parts of indoleacetic acid, 2 to 4 parts of gibberellin, 1 to 6 parts of aminoethoxyvinylglycine, 2 to 8 parts of aminooxyacetic acid, 1 to 3 parts of silver nitrate, 2 to 4 parts of silver thiosulfate, 5 to 12 parts of diethyl aminoethyl hexanoate, 5 to 8 parts of forchlorfenuron, 8 to 12 parts of compound sodium nitrophenolate, 7 to 10 parts of thiocarbamide, 6 to 10 parts of chloroethanol, 6 to 12 parts of hydrogen peroxide, 3 to 5 parts of brassinolide, 3 to 5 parts of triacontanol, 5 to 8 parts of paclobutrazol, and 1 to 2 parts of chlormequat chloride. The special florescence prolonging medicament for the flower of the rape flower has the beneficial effects that the special florescence prolonging medicament for the flower of the rape flower, which is provided by the invention, can effectively prolong the florescence of the flower, is further small in toxic action, and basically has no influence on an environment.

Owner:LIUZHOU GENGQING TECH

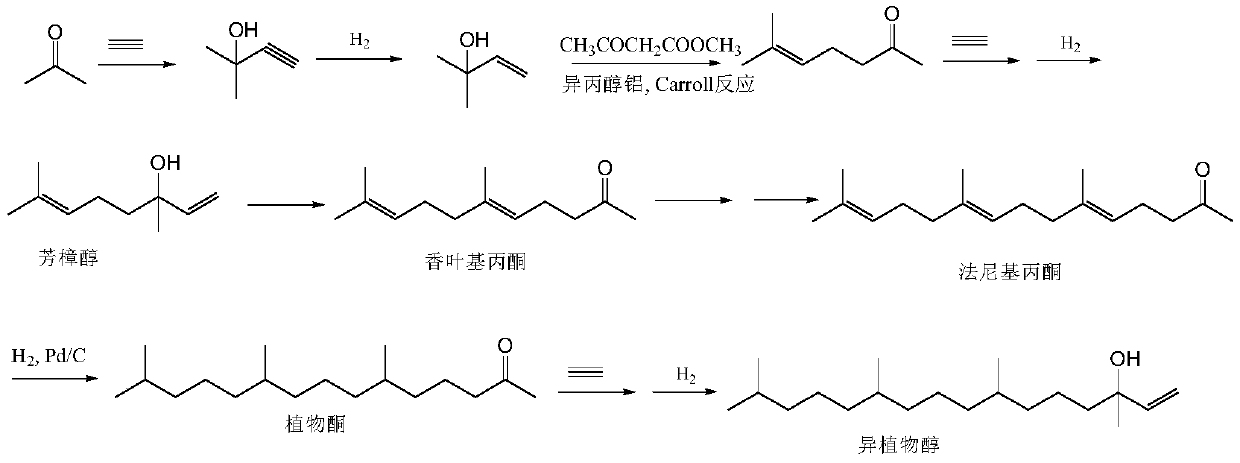

Synthesis method of intermediate farnesyl acetone and method for synthesizing phytol, isophytol and geranyl geraniol by using intermediate farnesyl acetone

ActiveCN111393275AShort synthetic routeReduce dosagePreparation by isomerisationOrganic compound preparationVitamin K2Side chain

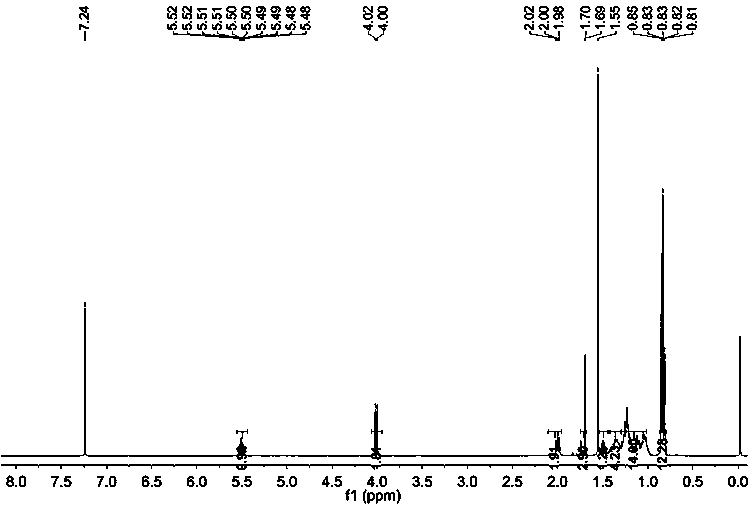

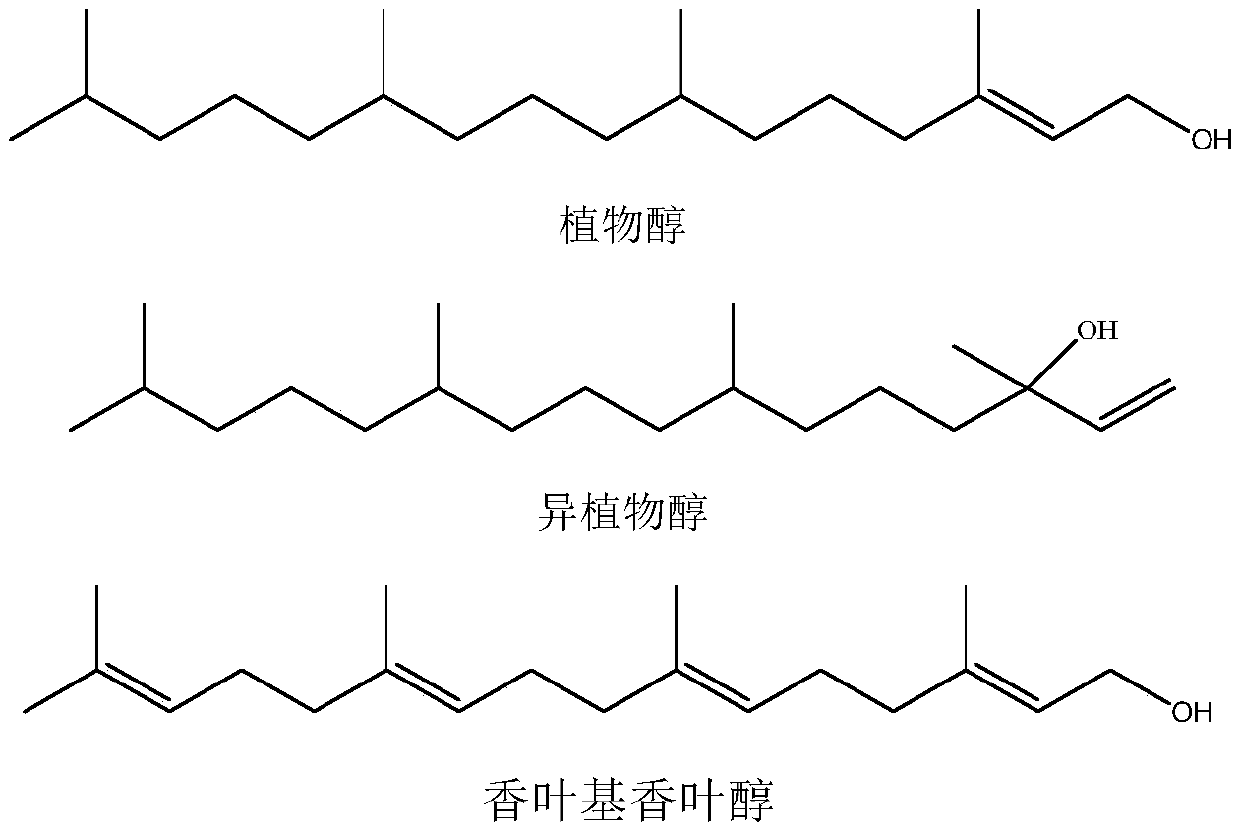

The invention relates to a synthesis method of an intermediate farnesyl acetone, and a method for synthesizing vitamin E, vitamin K1, vitamin K2 side chain isophytol, phytol and geranyl geraniol by utilizing farnesyl acetone. Specifically, the method includes: taking acetone and 5-chloro-2-pentanone as the raw materials, carrying out three Grignard reactions to obtain a key intermediate farnesyl acetone, and hydrogenating the farnesyl acetone to obtain phytol ketone; reacting farnesyl acetone with a vinyl chloride Grignard agent to obtain geranyl linalool, and conducting rearrangement under acid catalysis to obtain geranyl geraniol; or reacting the farnesyl acetone directly with a hydroxyl-protected 2-chloroethanol Grignard agent to obtain geranyl geraniol; reacting phytol ketone with a vinyl chloride Grignard agent to obtain isophytol, and rearranging the isophytol under acid catalysis to obtain phytol; or directly reacting the phytol with a hydroxyl-protected 2-chloroethanol Grignardagent to obtain the phytol. The method has the advantages of cheap and easily available initial raw materials, short synthesis process steps, low product cost and the like.

Owner:SHANGHAI MODERN HASEN SHANGQIU PHARMA +1

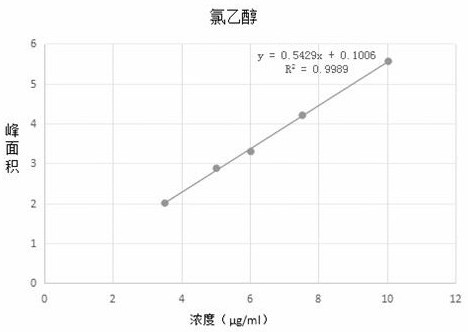

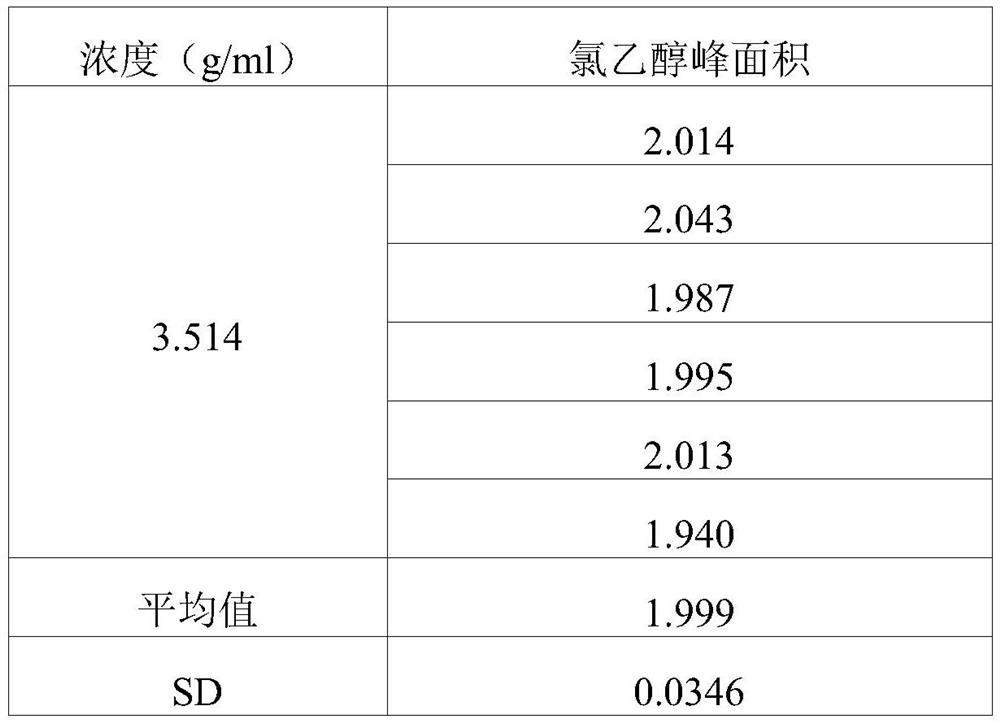

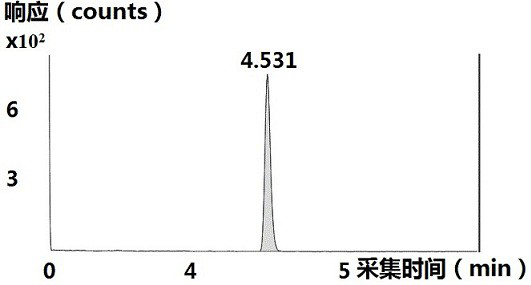

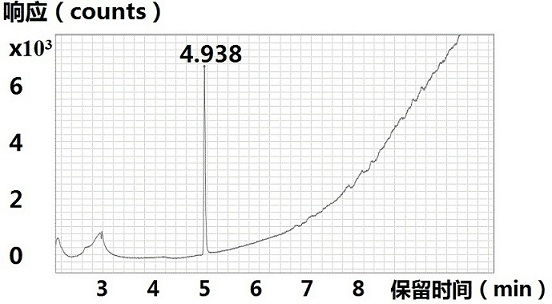

Method for determining content of chloroethanol in gelatin hollow capsule

PendingCN113552230AHigh penetration rateReduce use costComponent separationGas liquid chromatographicEngineering

The invention discloses a method for determining the content of chloroethanol in a gelatin hollow capsule, which comprises the following steps: step 1, preparing a test solution, taking a proper amount of gelatin hollow capsule, cutting into pieces, weighing, placing in a headspace bottle, precisely adding n-hexane, sealing, dipping overnight, taking the subsequent filtrate as the test solution, and preparing a blank sample by using the n-hexane to perform a blank test; step 2, preparing a reference substance solution, taking a proper amount of a chloroethanol reference substance, precisely weighing, dissolving with n-hexane, and quantitatively diluting chloroethanol to prepare a solution; and step 3, determination: taking the test solution, the blank sample and the reference solution prepared in the step 1 and the step 2, and carrying out gas chromatograph detection on the test solution, the blank sample and the reference solution. The detection method provided by the invention is verified by a test, and a result shows that the method is strong in specificity, good in precision and high in accuracy, and the content of chloroethanol can be rapidly measured.

Owner:JIANGSU TASLY DIYI PHARMA CO LTD

Special florescence prolonging medicament for convallaria majalis flowers

InactiveCN104824022AProlong flowering periodToxic reductionPlant growth regulatorsBiocideBiotechnologyH2O2 - Hydrogen peroxide

The invention discloses a special florescence prolonging medicament for convallaria majalis flowers. The special florescence prolonging medicament is prepared from the following raw materials in parts by weight: 5-10 parts of 6-benzoyladenine, 6-12 parts of naphthaleneacetic acid, 4-8 parts of 2, 4-dichlorophenoxyacetic acid, 3-8 parts of ethephon, 2-4 parts of gibberellin, 1-6 parts of aminoethoxyvinylglycine, 2-8 parts of aminoxyacetic acid, 1-3 parts of silver nitrate, 2-4 parts of silver thiosulfate, 5-12 parts of diethyl aminoethyl hexanoate, 5-8 parts of forchlorfenuron, 8-12 parts of compound sodium nitrophenolate, 7-10 parts of thiourea, 6-10 parts of chloroethanol, 6-12 parts of hydrogen peroxide, 3-5 parts of brassinolide, 3-5 parts of triacontanol, 5-8 parts of paclobutrazol and 1-2 parts of chlormequat chloride. The invention has the beneficial effects that the special florescence prolonging medicament for convallaria majalis flowers, provided by the invention, can effectively prolong the florescence of the flowers, has small toxic and harmful effects and has almost no impact on the environment.

Owner:LIUZHOU GENGQING TECH

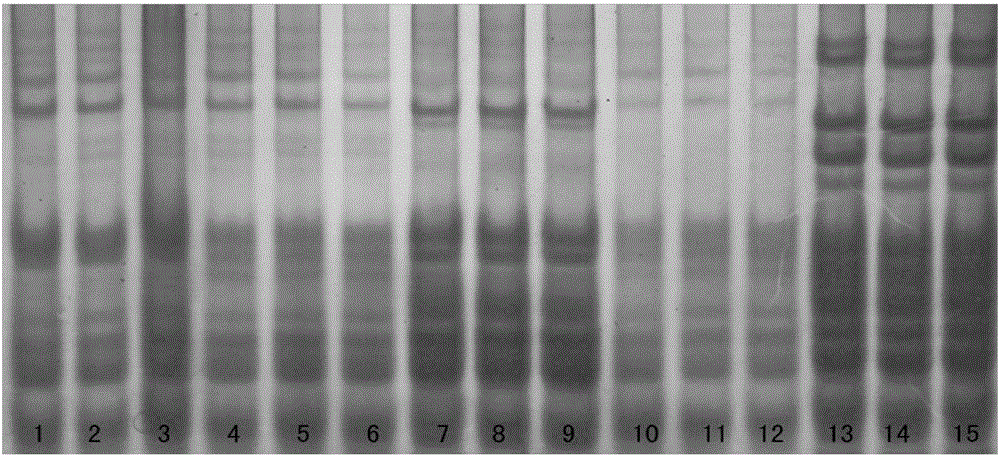

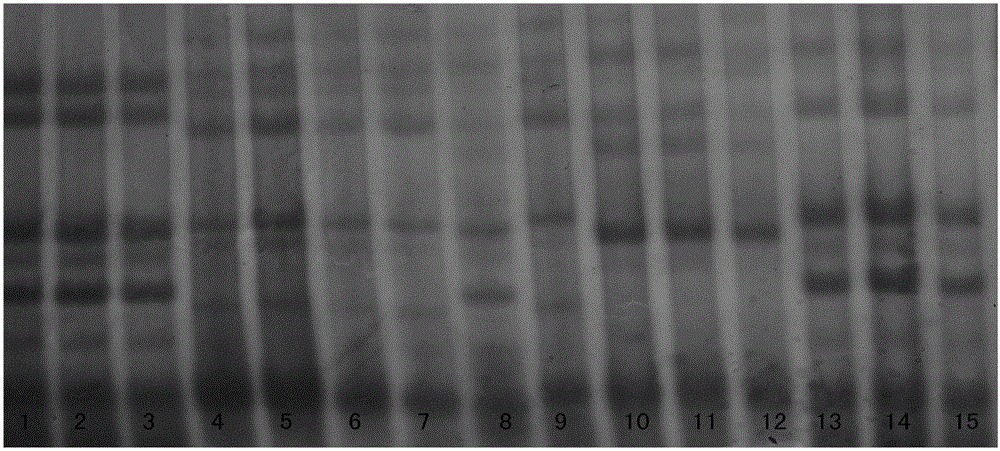

Wheat seed purity identification method

InactiveCN104990969AReduce poisonReduce pollutionMaterial electrochemical variablesBiotechnologyMolecular sieve

The invention discloses a wheat seed purity identification method which is developed on the basis of conventional methods. The identification method has the following improvements: (1) nontoxic and harmless ethanol is used to replace alpha-chloroethanol as an extraction liquid, and thus the harm to human body and pollution to environment are both effectively reduced; (2) the acrylamide concentration and crosslinking degree are properly adjusted, thus the film becomes tough and elastic, and the functions of molecular sieve can be better exerted; (3) the gel can be filled in one step, and the steps are saved. The provided identification method has the characteristics of concise technology process, simple operation, short time, and environment-friendliness. Moreover, a novel film washing and preservation technology is adopted, the background of the washed film is clear, the film can be preserved for a long time after the film is soaked in a preservation liquid and sealed by a preservative film, and thus the film can be applied to the post identification and research.

Owner:SHANDONG CROP GERMPLASM CENT

Preparation method of theic

ActiveCN112300089AReduce the temperatureReduce generationOrganic chemistryPtru catalystPhysical chemistry

The invention relates to the field of organic chemical industry, in particular to a preparation method of tris (2-hydroxyethyl) isocyanurate. According to the method, a chloroethanol route is used, iodide ions are used as a catalyst, a proper feeding mode and a purification method are adopted, and the defects that the method is complex in process, long in reaction period and inconvenient in excessive recovery of chloroethanol are overcome. Iodine ions are used as a catalyst so that the temperature during the reaction of chloroethanol and cyanuric acid is reduced. Meanwhile, the equivalent chloroethanol is added in a dropwise adding manner so that the self reaction of the chloroethanol and the generation of impurities generated by the reaction of the theic and the chloroethanol are reduced,the operation is simple, the purification is convenient, and the industrial prospect is better.

Owner:山东键邦新材料股份有限公司

Special flowering phase prolonging chemical for nerium oleander flowers

InactiveCN104839213AProlong flowering periodToxic reductionBiocidePlant growth regulatorsBenzoic acidEthephon

The invention discloses a special flowering phase prolonging chemical for nerium oleander flowers. The special flower phasing prolonging chemical is prepared by adopting the following raw materials in parts by weight: 4 to 8 parts of 2,4-dichlorphenoxyacetic acid, 3 to 8 parts of ethephon, 2 to 6 parts of triiodobenzoic acid, 2 to 4 parts of indoleacetic acid, 2 to 4 parts of gibberellins, 1 to 6 parts of aminoethoxyvinylglycine, 2 to 8 parts of aminooxyacetic acid, 1 to 3 parts of silver nitrate, 2 to 4 parts of silver thiosulfate, 5 to 12 parts of diethylaminoethyl hexanoate, 5 to 8 parts of forchlorfenuron, 8 to 12 parts of compound sodium nitrophenolate, 7 to 10 parts of thiourea, 6 to 10 parts of ethylene chlorohydrins, 6 to 12 parts of hydrogen peroxide, 3 to 5 parts of brassinolide, 3 to 5 parts of triacontanol, 5 to 8 parts of paclobutrazol and 1 to 2 parts of chlormequat chloride. By adopting the special flowering phase prolonging chemical for the flowers, the flowering phase of the flowers can be effectively prolonged, the toxicity is small, and the environment is hardly affected.

Owner:LIUZHOU GENGQING TECH

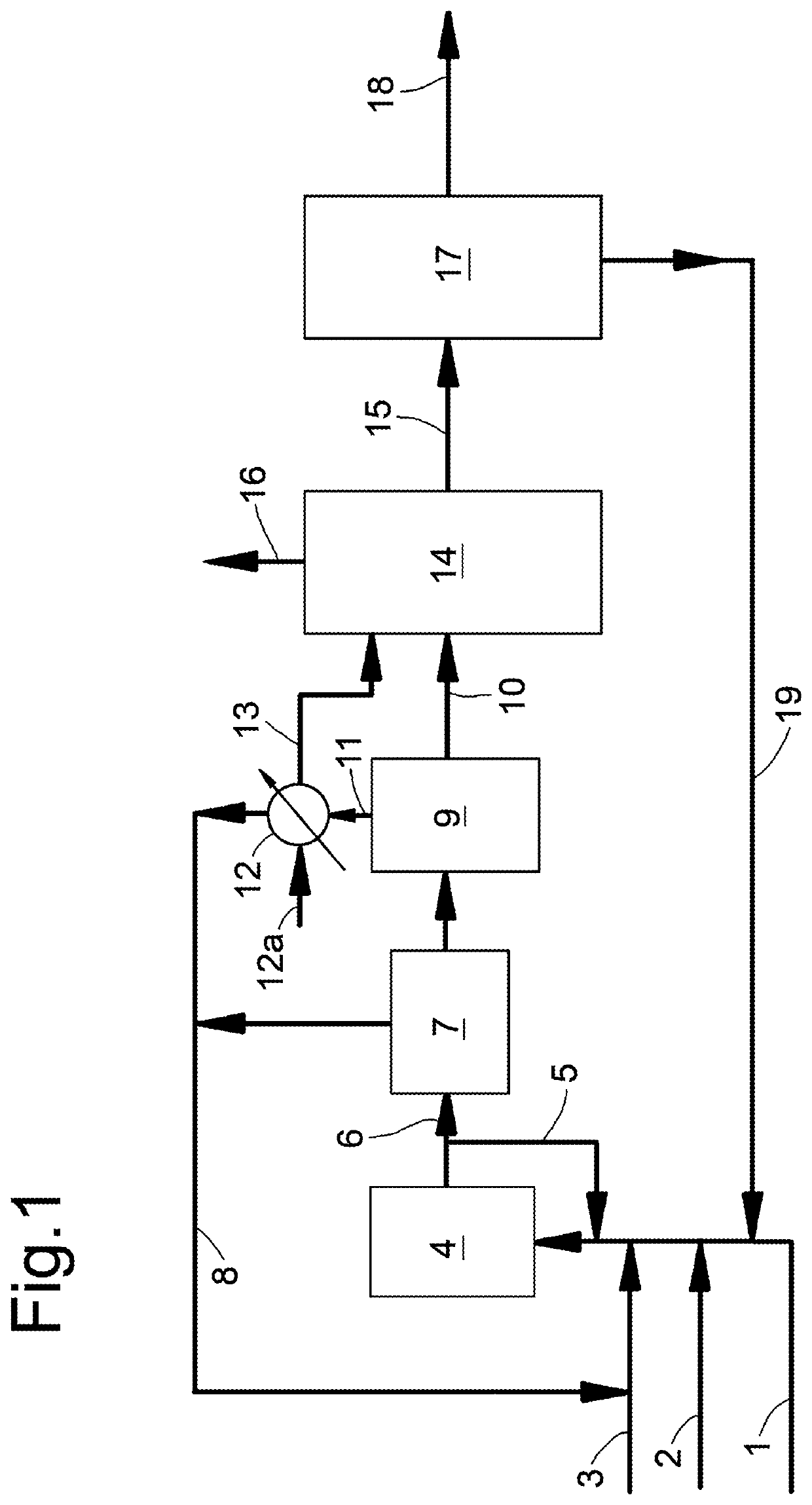

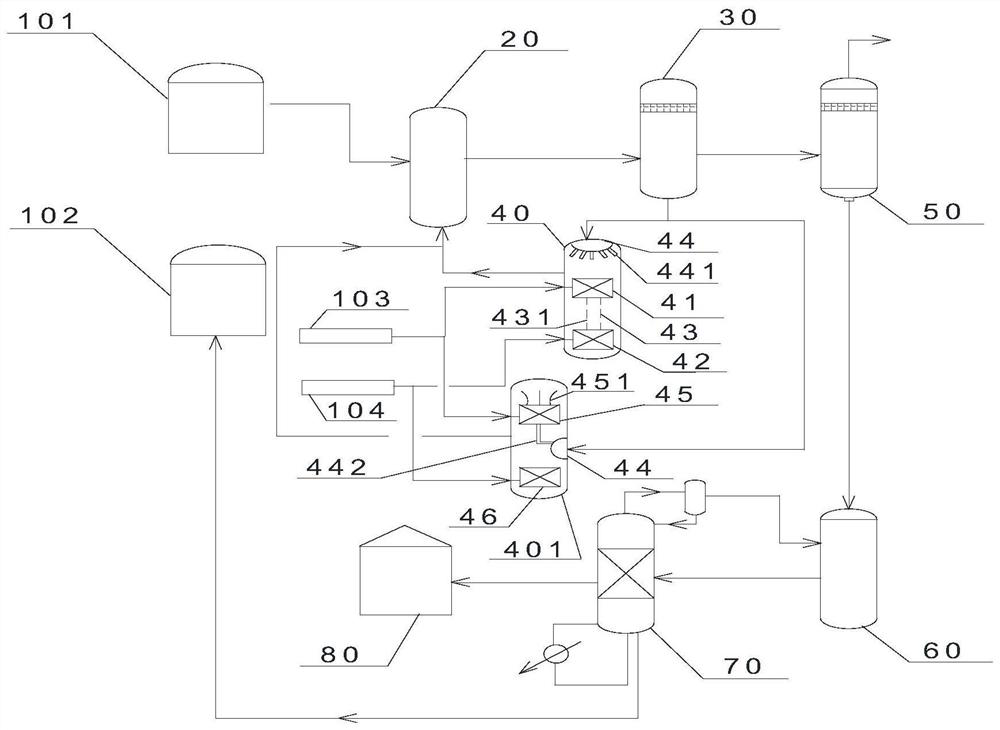

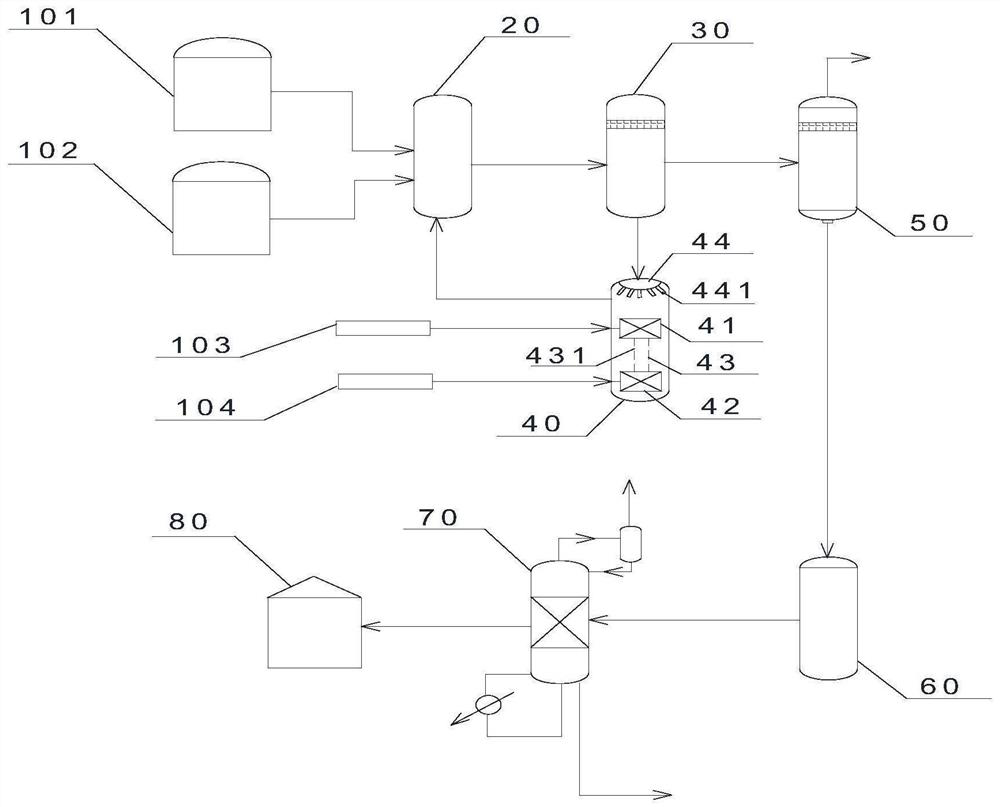

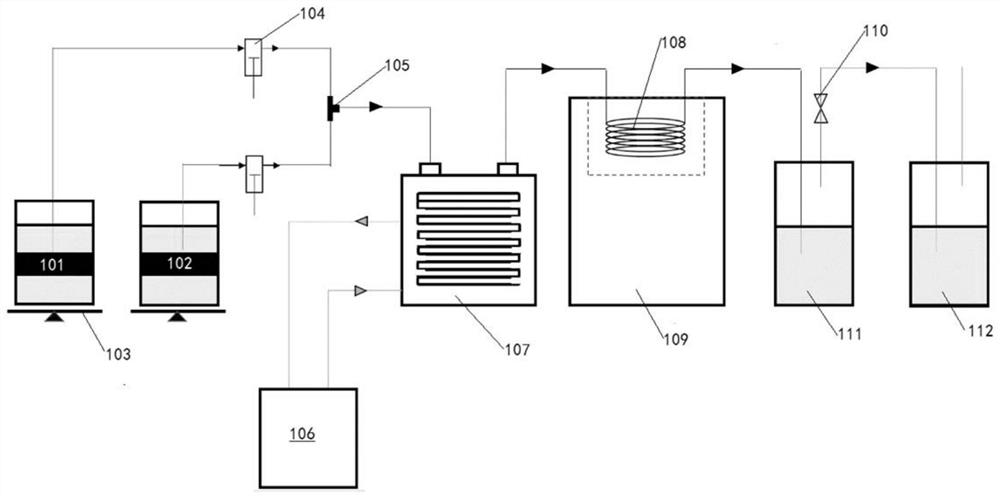

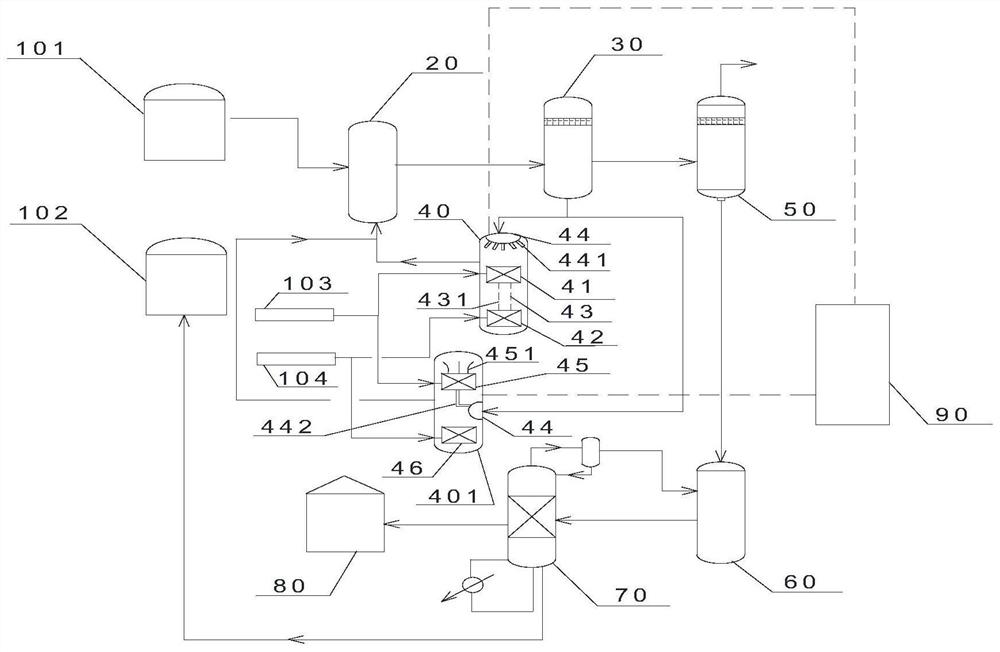

Micro-interface reaction system and method for preparing ethylene glycol by chloroethanol method

PendingCN112479812AIncrease profitLow costProductsOrganic compound preparationSodium bicarbonateInterfacial reaction

The invention discloses a micro-interface reaction system for preparing ethylene glycol by a chloroethanol method. The micro-interface reaction system comprises a main material reactor, a crystallizer, a first recycling reactor and a second recycling reactor, wherein the main material reactor is connected with a sodium bicarbonate storage tank and a chloroethanol storage tank, a product obtained after reaction of the main material reactor enters the crystallizer, and the crystallizer is connected with the first recycling reactor and the second recycling reactor; a first ammonia gas micro-interface generator and a carbon dioxide micro-interface generator are arranged in the first recycling reactor, and a second ammonia gas micro-interface generator and a split-flow type micro-interface generator are arranged in the second recycling reactor; the first recycling reactor and the second recycling reactor are connected with the main material reactor and are used for returning the generated sodium bicarbonate to the main material reactor. According to the reaction system, the cost of the reaction process is reduced, and the reaction efficiency is enhanced.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

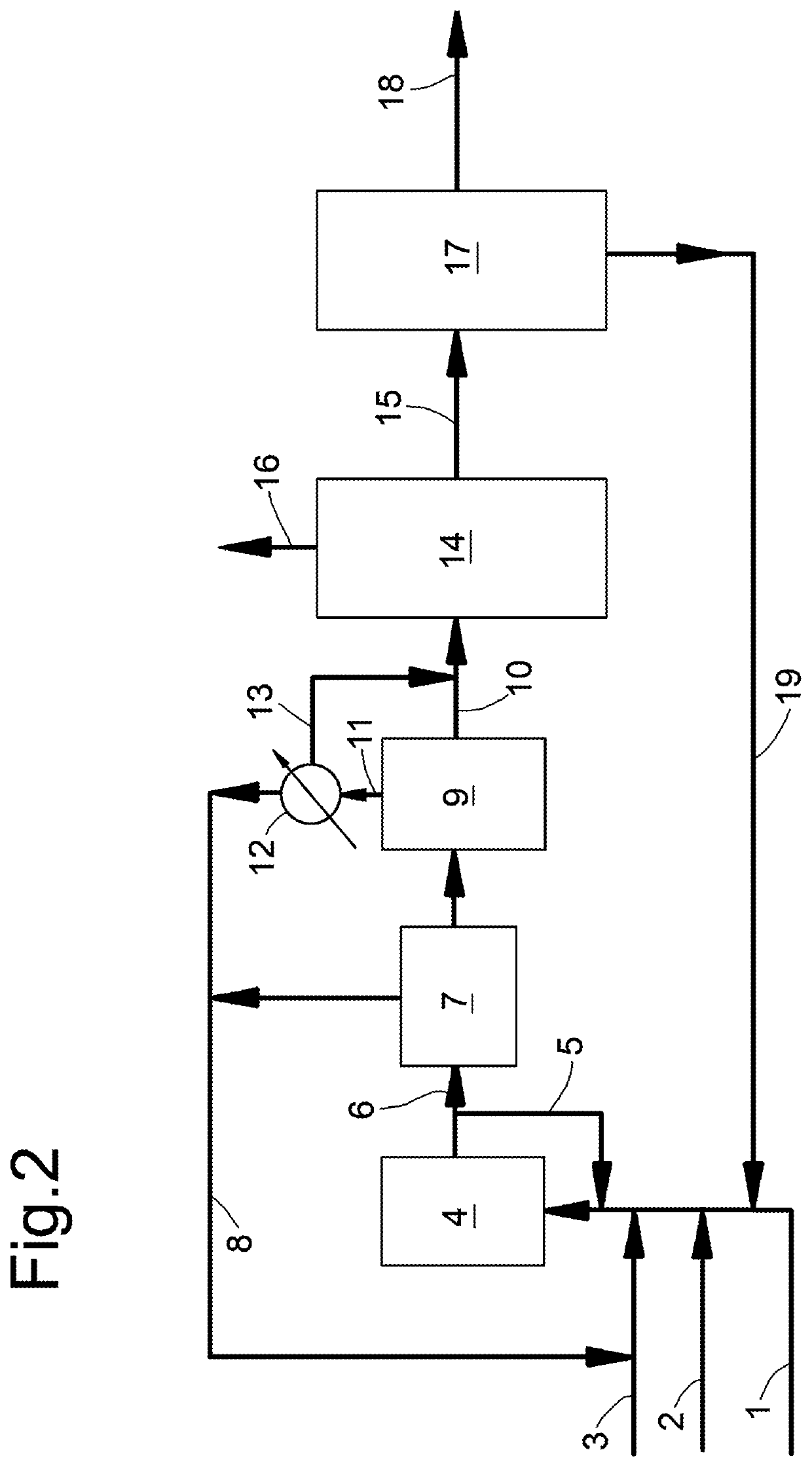

Reaction system and method for preparing ethylene glycol by chloroethanol method

InactiveCN112645795ALow costIncrease mass transfer rateOrganic compound preparationHydroxy compound separation/purificationSodium bicarbonateEngineering

The invention discloses a reaction system for preparing ethylene glycol by a chloroethanol method. The reaction system comprises a main material reactor, a recycling reactor and a crystallizer; the main material reactor is connected with a sodium bicarbonate storage tank and a chloroethanol storage tank, a product obtained after reaction of the main material reactor enters the crystallizer, and the crystallizer is connected with the recycling reactor; and an ammonia gas micro-interface generator and a carbon dioxide micro-interface generator are arranged in the recycling reactor, the ammonia gas micro-interface generator is connected with an ammonia gas inlet pipeline, and the carbon dioxide micro-interface generator is connected with a carbon dioxide inlet pipeline. According to the reaction system, the cost of the reaction process is reduced, and the reaction efficiency is enhanced.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

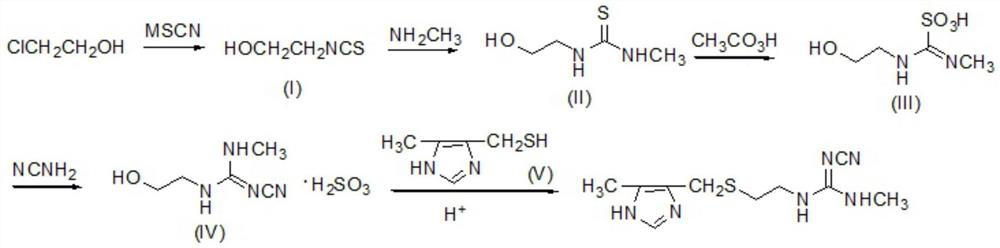

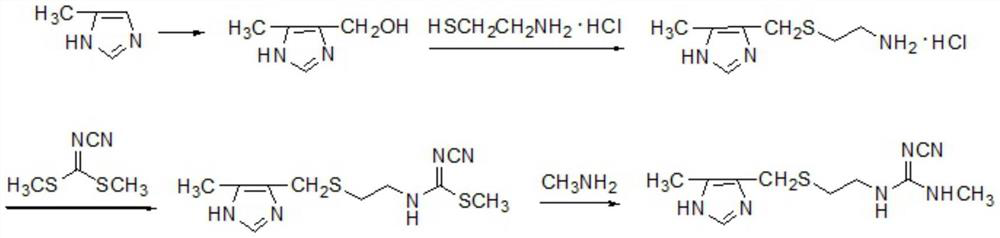

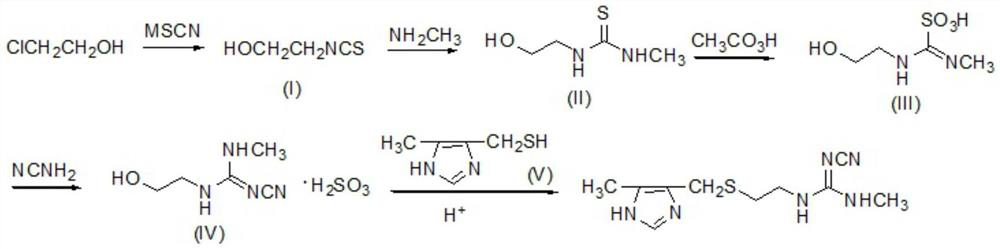

Production method of cimetidine

ActiveCN113234018AAvoid it happening againReduce pollutionOrganic chemistryThiolEnvironmental engineering

The invention relates to a production method of cimetidine, the production method comprises the following steps: (1) reacting 2-chloroethanol with thiocyanate to prepare an intermediate (I); (2) reacting the intermediate (I) with methylamine to prepare an intermediate (II); (3) oxidizing the intermediate (II) with oxyacetic acid to obtain an intermediate (III); (4) condensing the intermediate (III) and cyanamide to obtain an intermediate (IV); and (5) condensing the intermediate (IV) and imidazole mercaptan (V) to prepare cimetidine. The production method of cimetidine is provided, the production method can avoid the environmental pollution caused by the by-product methyl mercaptan generated in the existing cimetidine production, and is simple in production process, low in production cost and suitable for industrial production.

Owner:SHIJIAZHUANG POLEE PHARMA CO LTD

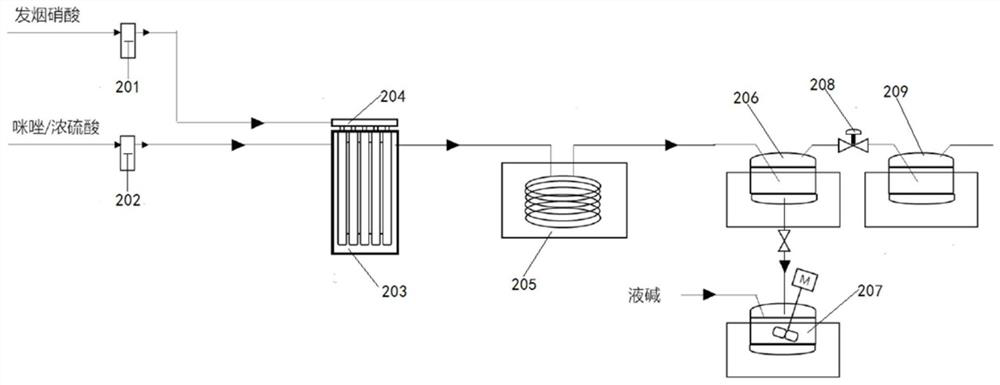

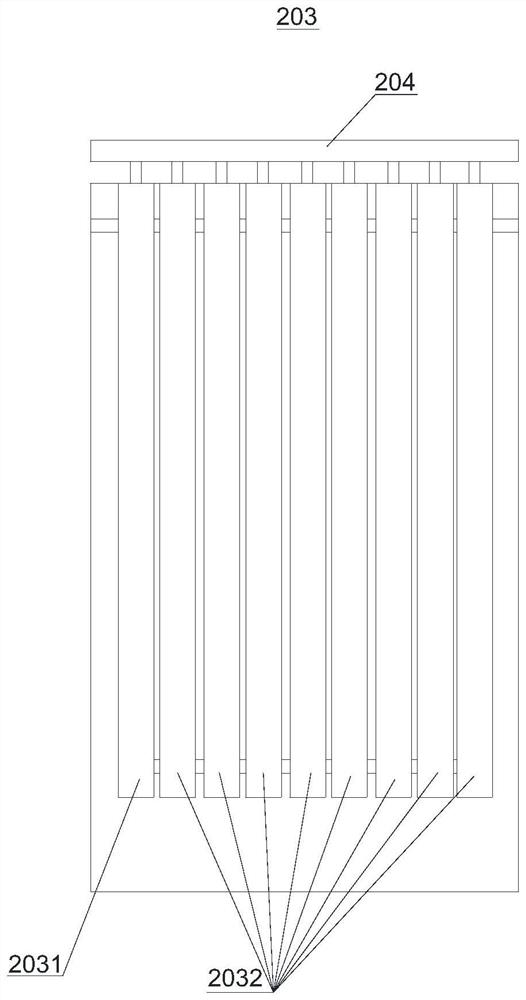

Continuous synthesis method of metronidazole

PendingCN114573511AIncrease the specific surface area of the reactionImprove heat transfer efficiencyProcess control/regulationOrganic chemistryNitroimidazoleChemical synthesis

The invention discloses a metronidazole continuous synthesis method, and relates to the technical field of chemical synthesis. The metronidazole continuous synthesis method comprises the following steps: heating an acidic solution containing 2-methyl-5-nitroimidazole and 2-chloroethanol to carry out a hydroxyethylation reaction, cooling a reaction solution flowing out of a hydroxyethylation microchannel reactor after the reaction is completed, adjusting the pH value of the reaction solution to 3-4, carrying out solid-liquid separation, taking a filtrate, adjusting the pH value of the filtrate to 9-11, and carrying out solid-liquid separation to obtain the metronidazole. And crystallizing to obtain a metronidazole crude product, and recrystallizing to obtain metronidazole. The 2-methyl-5-nitroimidazole and the 2-chloroethanol are in a dissolved and clarified state under the acidic condition and can be fed together, so that feeding and accurate metering are facilitated. In addition, the hydroxyethylation microchannel reactor is large in reaction specific surface area and high in heat exchange efficiency, the reaction temperature can be increased through pressurization, and after the reaction is completed, the remaining 2-chloroethanol is distilled off under reduced pressure, so that generation of a large amount of salt and wastewater is avoided.

Owner:ANHUI BIOCHEM UNITED PHARMA CO LTD

Method for synthesizing L-phenylalanine esterified bagasse xylan-g-VAc in ionic liquid

InactiveCN110713568AImprove biological activityAntineoplastic agentsPolymer scienceAcetic acid ethenyl ester

The invention discloses a method for synthesizing L-phenylalanine esterified bagasse xylan-g-VAc in an ionic liquid. The method comprises the following steps: by taking bagasse xylan as a main raw material, by taking vinyl acetate (VAc) as a grafting monomer and in a chlorinated-1-(2-hydroxyethyl)-3-methylimidazole ionic liquid solvent obtained by reaction of N-methylimidazole and chloroethanol, synthesizing bagasse xylan-g-VAc through initiation of ammonium sulfate; then by taking BOC-L-phenylalanine (tert-butyloxycarboryl-L-phenylalanine) subjected to acylating chlorination as an esterifyingagent, and taking 4-dimethylaminopyridine (DMAP) and cobalt naphthenate as a composite catalyst, carrying out catalytic esterification to synthesize a composite modified derivative that is the L-phenylalanine esterified bagasse xylan-g-VAc. The xylan derivative is endowed with specific activity to tumor cells, so that the xylan derivative has potential application value in the field of medicines.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Special medicament for prolonging flowering phase of catharanthus roseus flowers

InactiveCN104839217AProlong flowering periodToxic reductionBiocidePlant growth regulatorsBenzoic acidEthephon

The invention discloses a special medicament for prolonging flowering phase of catharanthus roseus flowers, which is prepared from the following raw materials in parts by weight: 5 to 10 parts of 6-benzyl aminopurine, 6 to 12 parts of naphthylacetic acid, 4 to 8 parts of 2, 4-dichlorphenoxyacetic acid, 3 to 8 parts of ethephon, 2 to 6 parts of tiba, 2 to 4 parts of heteroauxin, 2 to 4 parts of gibberellins, 1 to 6 parts of ammonia oxygen ethyl vinyl glycine, 2 to 8 parts of ammonia oxygen acetic acid, 1 to 3 parts of silver nitrate, 2 to 4 parts of silver thiosulfate, 5 to 12 parts of diethyl aminoethyl hexanoate, 7 to 10 parts of thiourea, 6 to 10 parts of chlorohydrins, 6 to 12 parts of hydrogen peroxide, 3 to 5 parts of brassinolide, 3 to 5 parts of triacontanol, 5 to 8 parts of paclobutrazol, 1 to 2 parts of chlormequat chloride. The special medicament for prolonging flowering phase of flowers, provided by the invention has the beneficial effects that by adopting the medicament, the flowering phase of flowers can be prolonged effectively, the toxic action is small, and the influence on the environment is basically avoided.

Owner:LIUZHOU GENGQING TECH

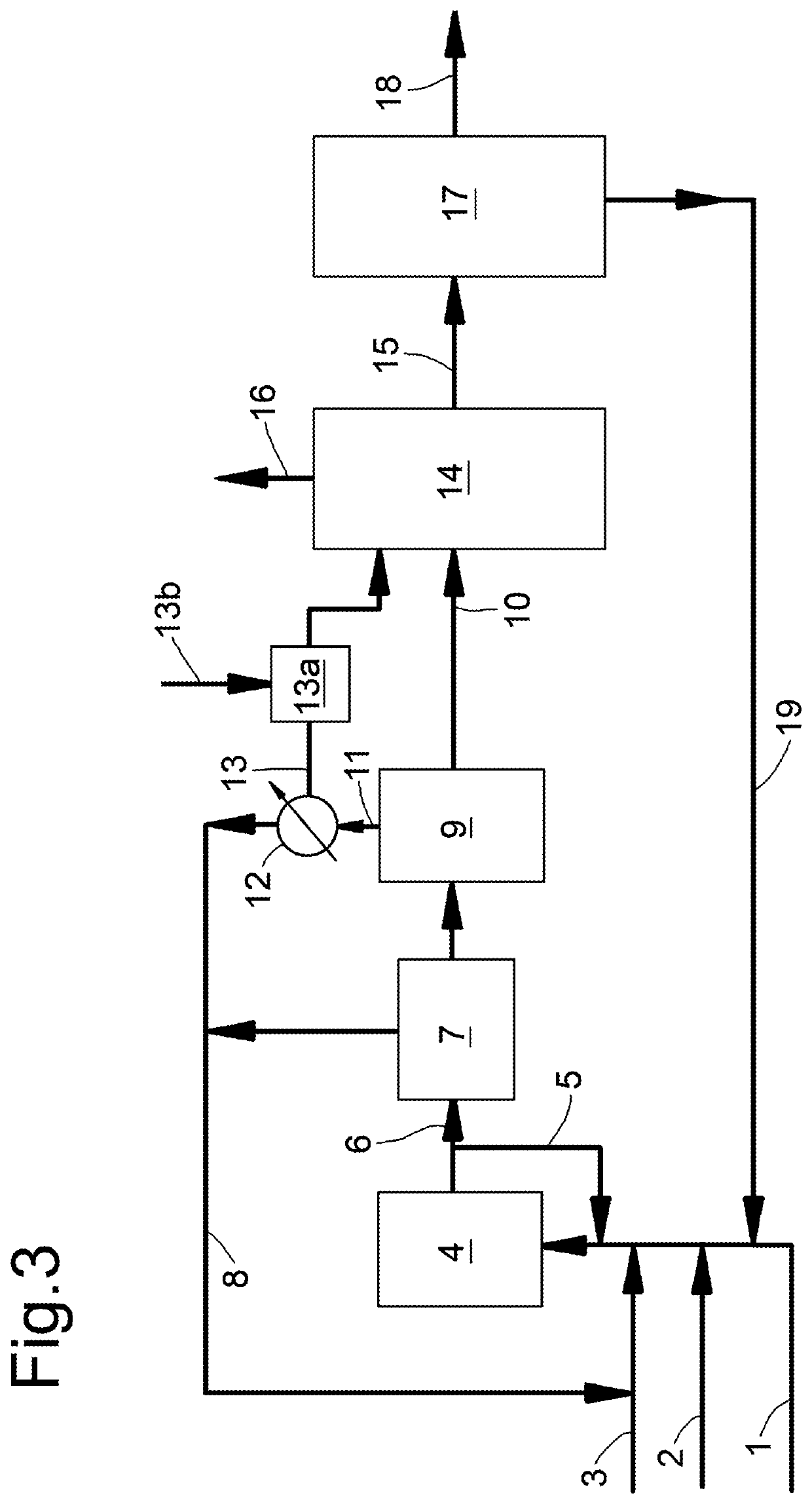

Intelligent micro-interface reaction system and method for preparing ethylene glycol via chloroethanol process

InactiveCN112624900ALow costControl spawn rateProcess control/regulationOrganic compound preparationSodium bicarbonateReaction rate

The invention discloses an intelligent micro-interface reaction system for preparing ethylene glycol via a chloroethanol process. The system comprises a main material reactor, a crystallizer, a first recycling reactor, a second recycling reactor and an intelligent control system, wherein the main material reactor is connected with a sodium bicarbonate storage tank and a chloroethanol storage tank; a product obtained after a reaction in the main material reactor enters the crystallizer; the crystallizer is connected with the first recycling reactor and the second recycling reactor; the first recycling reactor and the second recycling reactor are connected in parallel; a first ammonia gas micro-interface generator and a carbon dioxide micro-interface generator are arranged in the first recycling reactor; a second ammonia gas micro-interface generator and a split-flow type micro-interface generator are arranged in the second recycling reactor; and the intelligent control system controls reaction rates in the first recycling reactor and the second recycling reactor. According to the reaction system, the cost of the reaction process is reduced, and reaction efficiency is enhanced.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

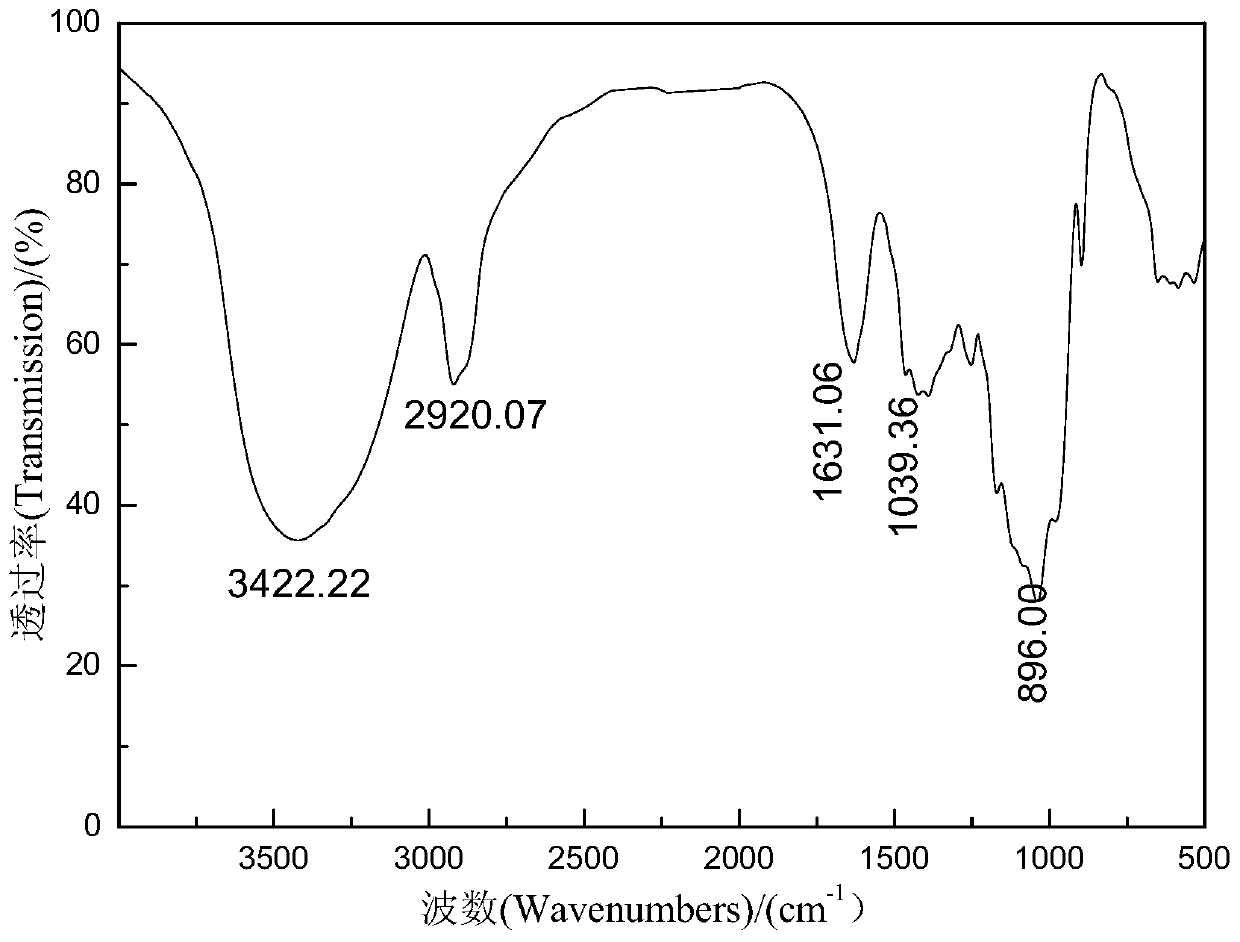

Method for detecting chloroethanol in pharmaceutic adjuvant

The invention belongs to the technical field of pharmaceutical analysis. The invention provides a method for detecting chloroethanol in pharmaceutical excipients, which comprises the following steps: respectively dissolving a test sample and a reference substance with ultrapure water, and extracting with ethyl acetate to respectively obtain a test sample solution and a reference substance solution; respectively injecting the test solution and the reference solution into a gas chromatograph-mass spectrometer for analysis, and calculating the content of chloroethanol in the solutions by adopting a standard curve method. According to the detection method, methodological evaluation is carried out on the applicability, specificity, linearity and range, detection limit and quantitation limit, precision, accuracy and stability of the method system, the results all meet the requirements, and the detection method can be used for monitoring the content of chloroethanol in the pharmaceutic adjuvants.

Owner:广东国标医药科技有限公司

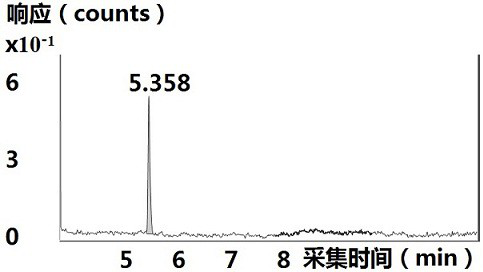

High-purity chlorohydrins and preparation method thereof

InactiveCN103641684AGood technical effectSimple process routePreparation by oxygen reductionReaction temperature2-Butene

The invention relates to the field of synthesis of chemical raw materials, and discloses a method for preparing high-purity chlorohydrins. The preparation method comprises the following steps: a, mixing a raw material 1, 4-dichloro-2-butene and an ozonization reaction solvent; agitating; charging ozone to perform ozonization reaction; tracking the reaction through gas chromatography; and stopping the ozonization reaction until raw materials disappear; and b, charging nitrogen to remove the ozone from a reaction flask; adding a reducing agent to reduce at -10-30 DEG C; agitating; recovering the solvent under a normal pressure condition; and distilling and collecting fractions under normal pressure to obtain the high-purity chlorohydrins. The preparation method is simple and convenient in process route, small in pollution, high in yield, fast in reaction speed, and simple in post-treatment; the chlorohydrins have the purity exceeding 99%, and thus the industrial value is relatively high.

Owner:SHAOXING UNIVERSITY

Dedicated flowering phase prolonging agent for desert roses

InactiveCN104886125AProlong flowering periodToxic reductionBiocidePlant growth regulatorsBenzoic acidThiourea

The invention discloses a dedicated flowering phase prolonging agent for desert roses. The dedicated flowering phase prolonging agent for desert roses is prepared from the following raw materials in parts by weight: 5-10 parts of 6-benzylaminopurine, 6-12 parts of naphthylacetic acid, 4-8 parts of 2,4-dichlorphenoxyacetic acid, 3-8 parts of ethephon, 2-6 parts of triiodobenzoic acid, 2-4 parts of indoleacetic acid, 2-4 parts of gibberellin, 1-6 parts of aminoethoxyvinylglycine, 2-8 parts of aminooxyacetic acid, 5-12 parts of diethyl aminoethyl hexanoate, 5-8 parts of forchlorfenuron, 8-12 parts of compound sodium nitrophenolate, 7-10 parts of thiourea, 6-10 parts of chloroethanol, 6-12 parts of hydrogen peroxide, 3-5 parts of brassinolide, 3-5 parts of triacontanol, 5-8 parts of paclobutrazol and 1-2 parts of chlormequat chloride. The dedicated flowering phase prolonging agent for desert roses disclosed by the invention has the beneficial effects that the dedicated flowering phase prolonging agent for desert roses can be used for effectively prolonging the flowering phase of the flowers, and is less in toxic effect and substantially free of influence on the environment.

Owner:LIUZHOU GENGQING TECH

Process for destruction of gelled sulphur mustard

A process for the complete destruction of gelled sulphur mustard (SM), comprising the steps of: (a) dissolving gelled sulphur mustard (SM) in organic solvent such as 2-chloroethanol, methanol, methyl cellosolve or mixtures of these to obtain a clear mixture, (b) incinerating the clear gelled sulphur mustard solvent mixture obtained from step (a); (c) dissolving residual gelled SM obtained from step (c) into non-toxic products; (d) chemically converting dissolved SM obtained from step (c) into non-toxic products.

Owner:DIRECTOR GENERAL DEFENCE RES & DEV ORG

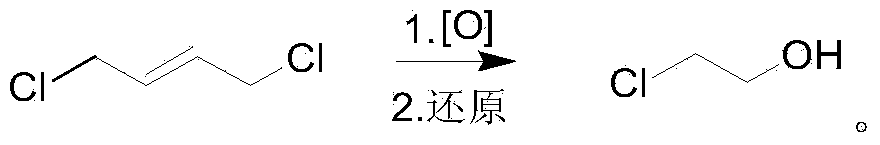

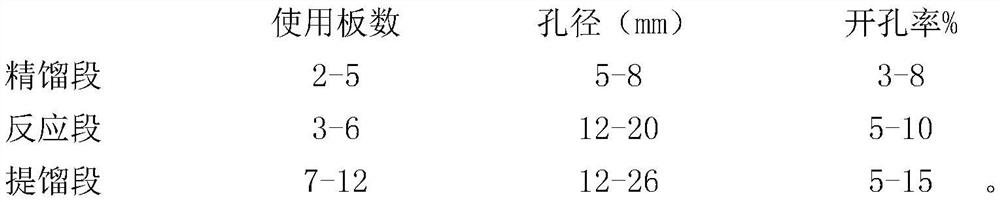

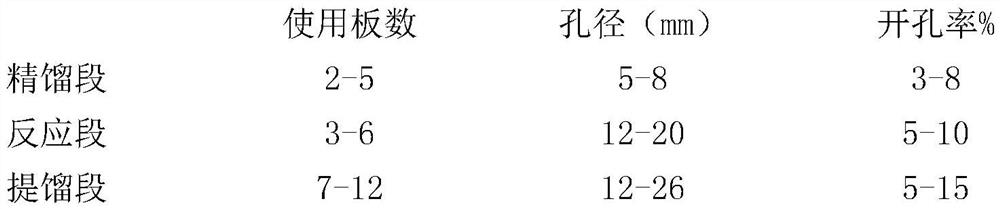

Method and equipment for preparing ethylene oxide from high-concentration chloroethanol

ActiveCN113248460AReduce contentLess waste waterOrganic chemistryFractional distillationHigh concentrationEthylene oxide

The invention relates to a method and equipment for preparing ethylene oxide from high-concentration chloroethanol. The method comprises the following steps: a 50-70wt% chlorohydrin aqueous solution and a lime milk solution are introduced into a pre-reactor and mixed; and the materials which stay and are mixed for 0.05-3 seconds enter a saponification rectifying tower, water vapor is introduced from the bottom of the tower for direct heating, steam at the top of the tower firstly enters a partial condenser, all condensed materials serve as reflux and flow back into the rectifying tower through a reflux tank, uncondensed steam from the partial condenser enters a total condenser to be completely condensed, and the product ethylene oxide is obtained. The saponification rectifying tower is a sieve-plate tower, and a rectifying section, a reaction section and a stripping section are sequentially arranged in the tower from top to bottom. The product yield is higher than 98%; and meanwhile, the amount of tower kettle wastewater and the content of organic matters in the wastewater are reduced.

Owner:HEBEI UNIV OF TECH

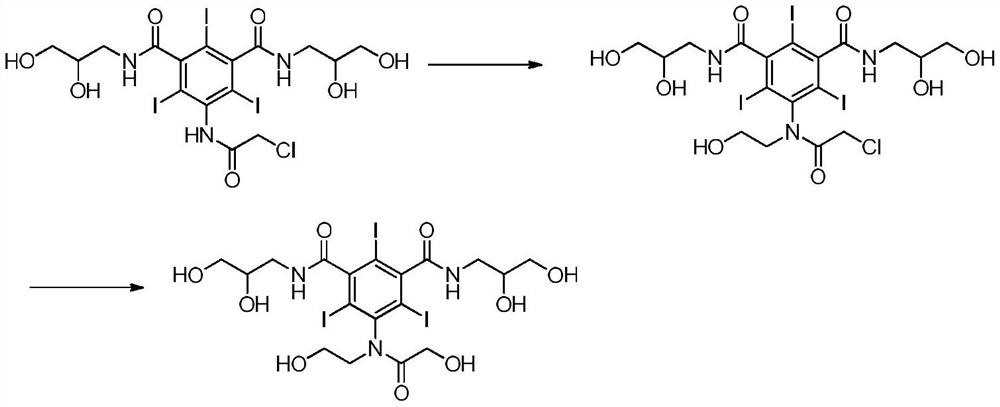

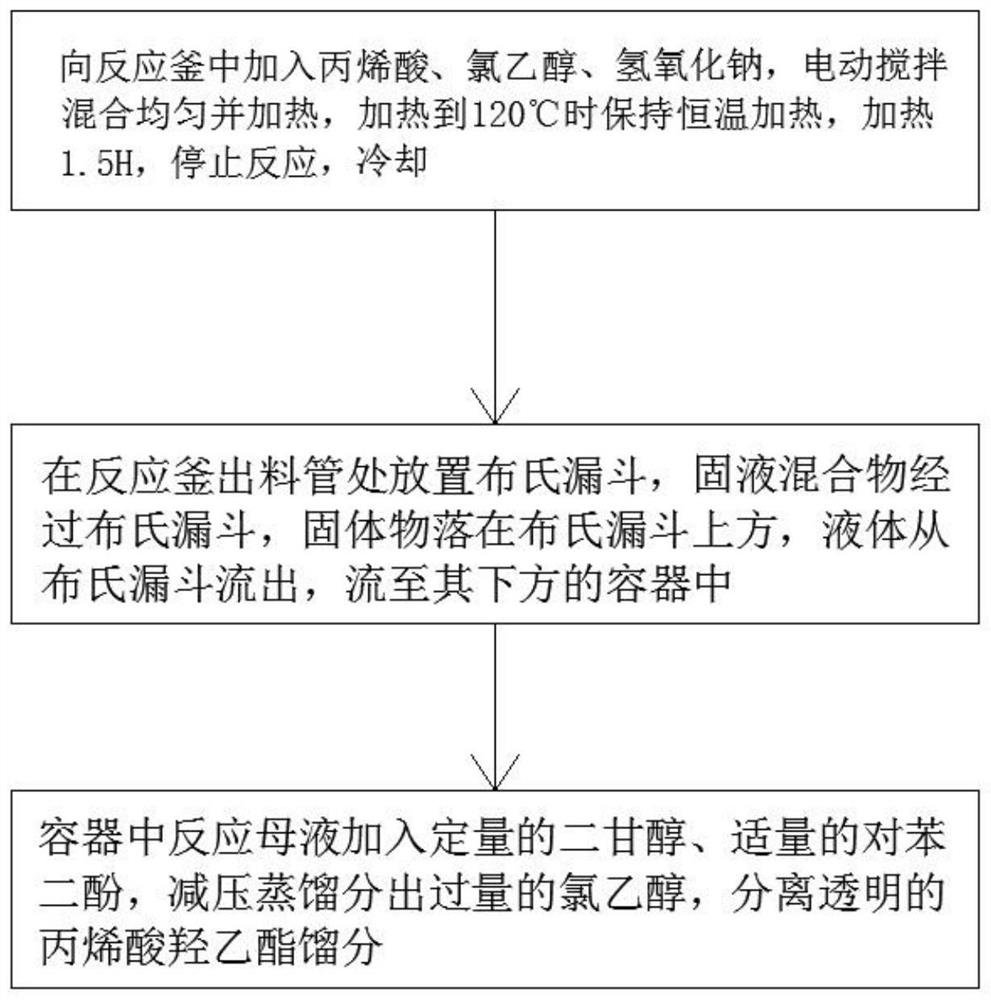

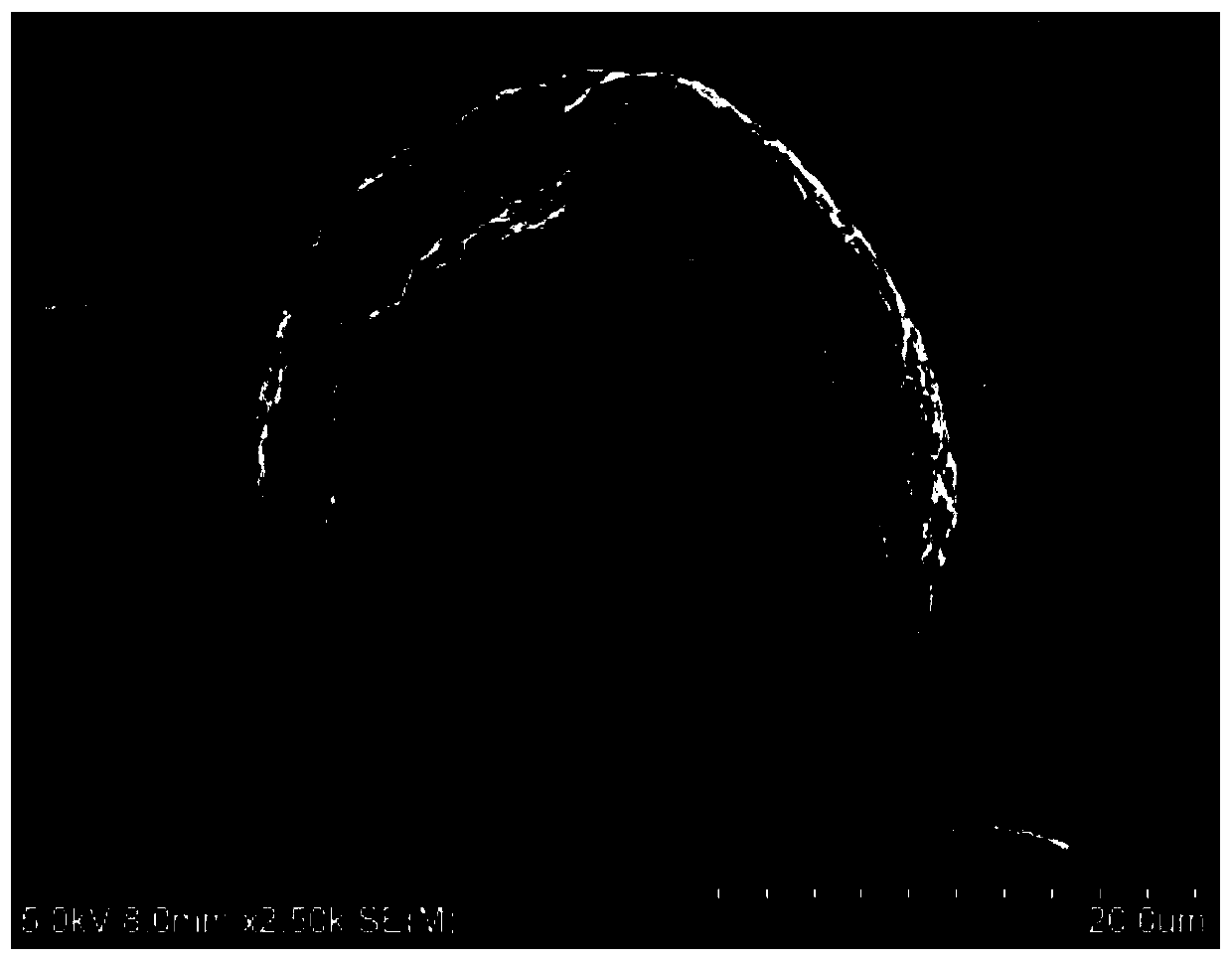

Synthesis method of thiodiethylene bis [3-(3, 5-di-tert-butyl-4-hydroxyphenyl) propionate]

ActiveCN114213291AHigh yieldHigh purityOrganic compound preparationCarboxylic acid esters preparationTert butyl phenolPropanoic acid

The invention relates to a synthesis method of thiodiethylene bis [3-(3, 5-di-tert-butyl-4-hydroxyphenyl) propionate]. The method comprises the following steps: enabling 2, 6-di-tert-butylphenol to react with acrylate, and continuing to react with 2-chloroethanol, so as to obtain an intermediate 3-(3, 5-di-tert-butyl-4-tetrahydroxyphenyl) propionic acid 2-chloroethyl ester; and reacting with sodium sulfide in the presence of quaternary ammonium salt to obtain a target product. The synthesis method disclosed by the invention has the advantages of simple process, high product yield and high purity, and is particularly suitable for being applied to industrial production.

Owner:JIANGSU JIYI NEW MATERIAL CO LTD

Special agent capable of prolonging flowering phase for geranium flower

InactiveCN104920456AProlong flowering periodToxic reductionBiocidePlant growth regulatorsBenzoic acidThiourea

The invention discloses a special agent capable of prolonging flowering phase for geranium flower. The agent is prepared from the following raw materials by weight: 5 to 10 parts of 6-benzylaminopurine, 6 to12 parts of naphthylacetic acid, 2 to 6 parts of triiodoberzoic acid, 2 to 4 parts of indole acetic acid, 2 to 4 parts of gibberellin, 1 to 6 parts of aminooxyethoxyvinylglycine, 2 to 8 parts of aminooxyacetic acid, 1 to 3 parts of silver nitrate, 2 to 4 parts of silver thiosulfate, 5 to 12 parts of diethyl aminoethyl hexanoate, 5 to 8 parts of forchlorfenuron, 8 to 12 parts of compound sodium nitrophenolate, 7 to 10 parts of thiourea, 6 to 10 parts of chloroethanol, 6 to 12 parts of hydrogen peroxide, 3 to 5 parts of brassinosteroid, 3 to 5 parts of triacontanol, 5 to 8 parts of paclobutrazol and 1 to 2 parts of cycocel. The invention has the following beneficial effects: the special agent capable of prolonging the flowering phase for flowers provided by the invention can effectively prolonging the flower phase of the flowers and has small toxic effect and no influence on the environment.

Owner:LIUZHOU GENGQING TECH

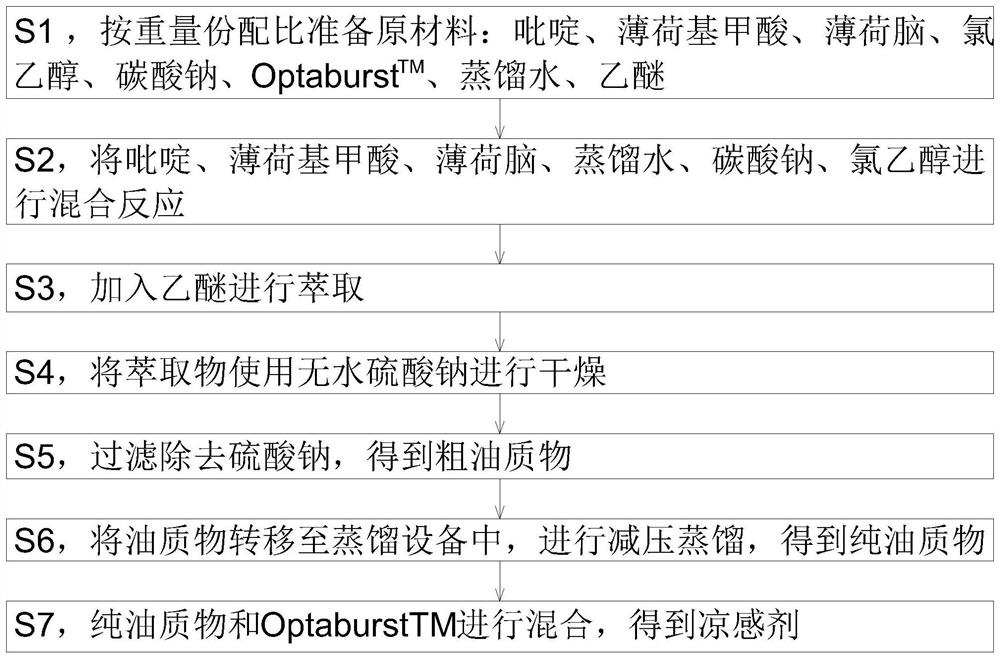

Cool feeling agent capable of continuously releasing cool feeling

PendingCN113633564ANot volatileGood saveCosmetic preparationsToilet preparationsMentholDistilled water

The invention discloses a cool feeling agent capable of continuously releasing cool feeling. The cool feeling agent comprises the following components in parts by weight: 10-20 parts of pyridine, 20-30 parts of menthyl formic acid, 15-35 parts of menthol, 15-25 parts of chloroethanol, 8-18 parts of sodium carbonate, 5-16 parts of OptaburstTM, 30-50 parts of distilled water and 25-38 parts of diethyl ether. The invention relates to the technical field of cool feeling agents. The cool feeling agent disclosed by the invention solves the problems that the cool feeling agent is easy to volatilize and difficult to store, the cool feeling duration is short, and the cool feeling agent has bitter taste.

Owner:上海驻净电子科技有限公司

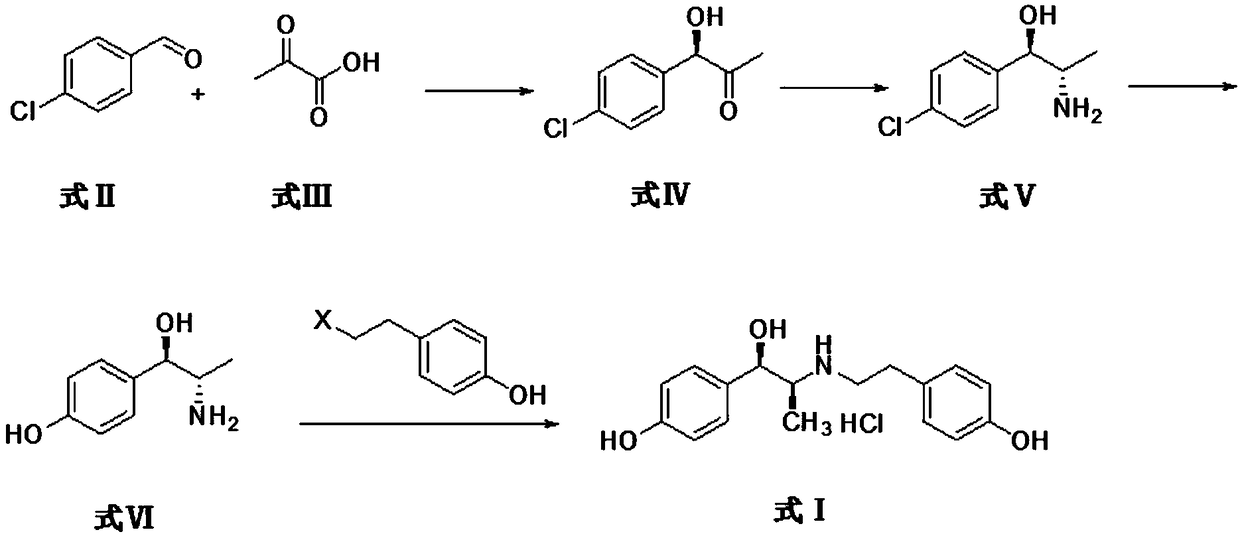

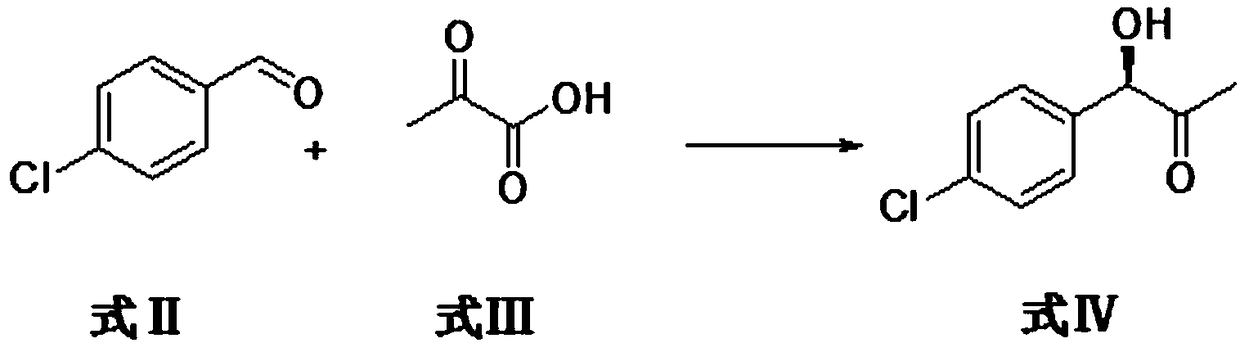

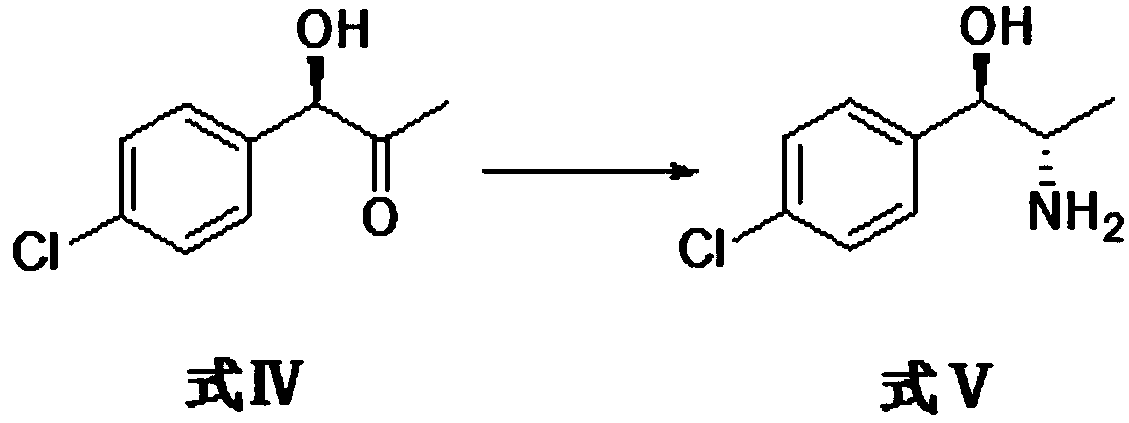

The synthetic method of ritodrine hydrochloride

InactiveCN107540563BSufficient supplyLow priceOrganic compound preparationFermentationChlorobenzeneP-chlorobenzaldehyde

The invention discloses a method for synthesizing ritodrine hydrochloride. The method comprises that p-chlorobenzaldehyde and pyruvic acid as substrates undergo a catalytic reaction, the product is purified to form (R)-1-(4-chlorophenyl)-1-hydroxypropane-2-one, the (R)-1-(4-chlorophenyl)-1-hydroxypropane-2-one and ammonium formate as substrates undergo a catalytic reaction, the product is purifiedto form (1R, 2S)-2-amino-1-(4-chlorophenyl)-1-propanol, the (1R, 2S)-2-amino-1-(4-chlorophenyl)-1-propanol and LiOH. H2O undergo a reaction to produce 4-((1R, 2S)-2-amino-1-hydroxypropyl)phenol and 4-((1R, 2S)-2-amino-1-hydroxypropyl)phenol and 4-(2-chloroethanol)phenol undergo a reaction to produce ritodrine hydrochloride. The method realizes a low cost, utilizes mild reaction conditions and issuitable for industrial production.

Owner:武汉茵茂特生物技术有限公司

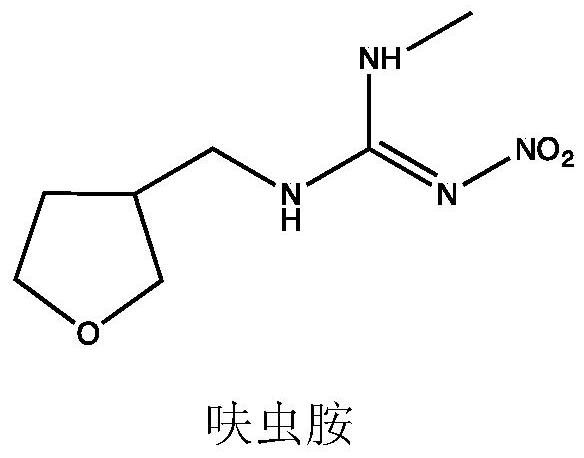

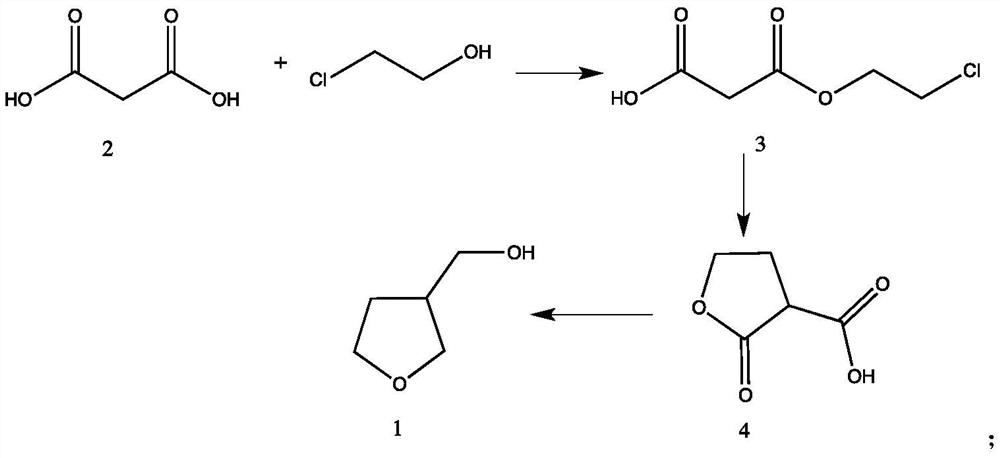

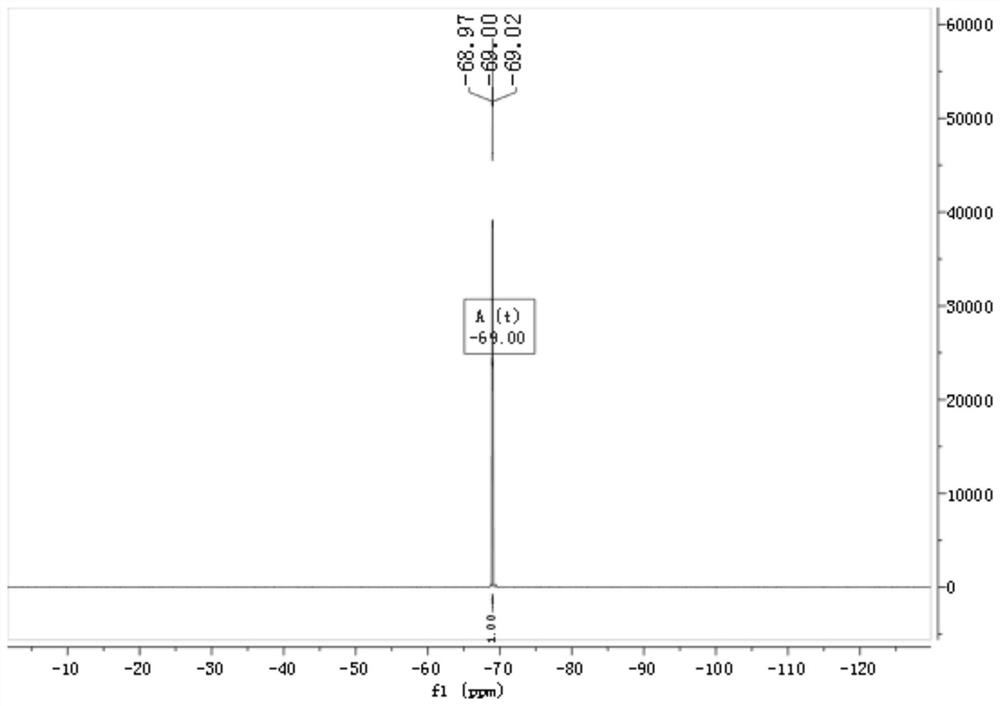

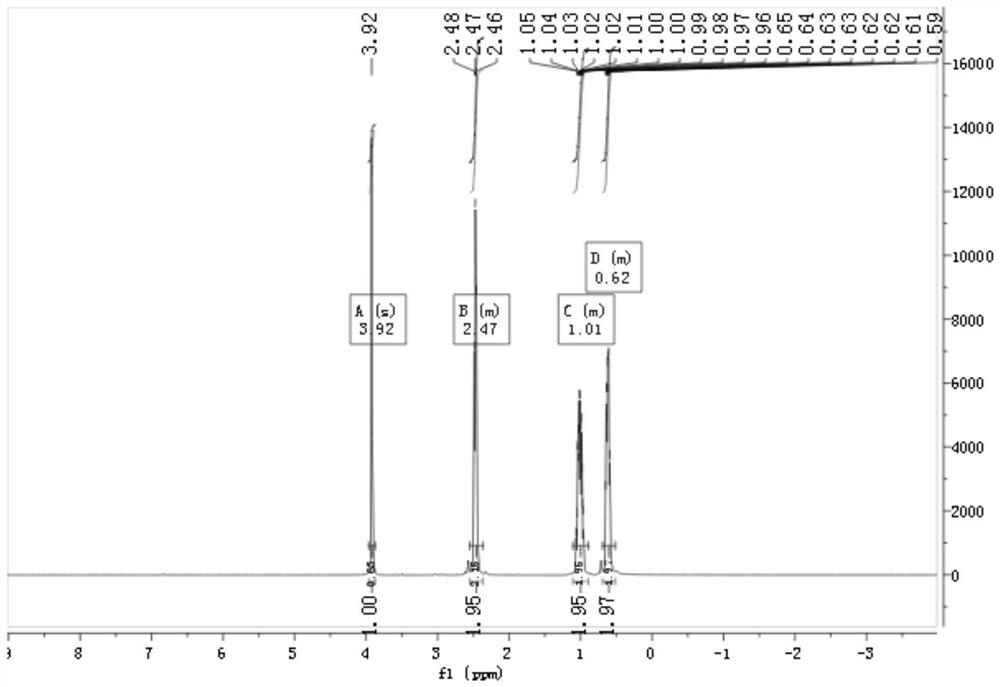

A kind of synthetic method of tetrahydro-3-furan methanol

The invention discloses a synthesis method of tetrahydro-3-furfuryl alcohol, and solves the problems of complicated route, operation difficulty, many three wastes and high cost of 3-hydroxymethyl-tetrahydrofuran synthesis in the prior art. The method comprises the following steps of (1) in an organic solvent, performing reaction on malonic acid and chlorohydrin under the existence of a catalyst A to produce ethyl oxalyl chloride; (2) performing closed loop reaction on the ethyl oxalyl chloride under the alkali effect to produce 3-formic acid-gamma-butyrolactone; (3) performing reduction and purification on the 3-formic acid-gamma-butyrolactone under the conditions of a reducing agent and a catalyst B to obtain 3-hydroxymethyl-tetrahydrofuran. The synthesis method has the advantages that the post treatment is simple; green and environment-friendly effects are achieved; the cost is low; the operation is simple; the yield is high, and the like.

Owner:CHENGDU ORGANOCHEM CO LTD

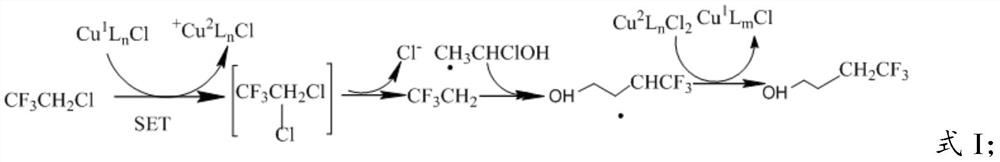

A kind of coupling synthesis method of 4,4,4-trifluorobutanol

ActiveCN109384651BHigh yieldProduce efficientlyOrganic compound preparationHydroxy compound preparationPtru catalystPhysical chemistry

The invention provides a novel method for coupling and synthesizing 4,4,4-trifluorobutanol, comprising the following steps: in the presence of a catalyst, 2,2,2-trifluoro-1-chloroethane and 1-chloroethanol is mixed in a solvent to carry out cross-coupling reaction to obtain 4,4,4-trifluorobutanol; the catalyst is a copper salt and an organic ligand; the copper salt is cuprous halide and / or chlorine copper chloride; the organic ligand is one or more of 2,2'-bipyridine, tetramethylethylenediamine and 4,4-di-tert-butyl-2,2,-bipyridine. The present invention uses copper salts and organic ligands as catalysts to catalyze the free radical cross-coupling reaction between 2,2,2-trifluoro-1 haloethane and 1-chloroethanol, and can efficiently prepare 4,4,4- Trifluorobutanol, the preparation method in the present invention has high selectivity and high yield. Experimental results show that the yield of the preparation method in the present invention is as high as 80%.

Owner:湖南有色郴州氟化学有限公司

Process for the preparation of ethylene glycol

The invention relates to a process for the preparation of ethylene glycol from ethylene, which comprises contacting the carbon dioxide stream resulting from hydrolysing ethylene carbonate, or the condensate stream resulting from condensing said carbon dioxide stream, or the waste water stream resulting from removing water from the ethylene glycol stream, such stream comprising water, 2-chloroethanol and ethylene glycol and additionally comprising 2-iodoethanol or 2-bromoethanol, with an alkali metal containing basic compound to form a mixture comprising water, 2-chloroethanol and ethylene glycol and additionally comprising alkali metal iodide or alkali metal bromide which mixture is dehydrated.

Owner:SHELL OIL CO

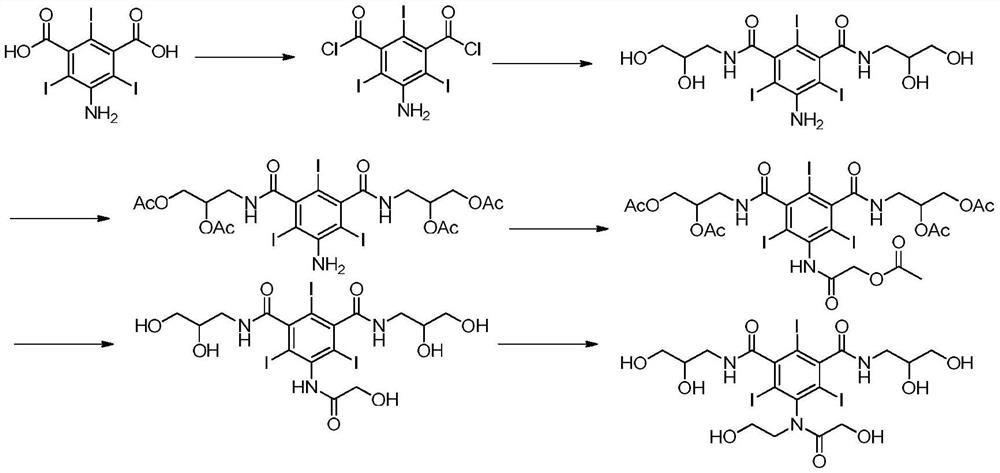

Method for preparing ioversol

PendingCN113717074AAvoid generatingImprove qualityOrganic compound preparationCarboxylic acid amides preparationBenzenePharmaceutical drug

The invention discloses a preparation method of a medicine namely ioversol, and belongs to the technical field of medical intermediates. The preparation method comprises the following steps: carrying out acetonylidene protection on (5-hydroxyacetamido)-N,N'-bis(2,3-dihydroxypropyl)-2,4,6-triiodine-1,3-benzene dicarboxamide (1) to obtain an intermediate (2), carrying out substitution reaction on the intermediate (2) and chlorohydrin to obtain an intermediate (3), and finally, carrying out acetonylidene removal protection reaction on the intermediate (3) to obtain ioversol. Through protection of different levels, no rearrangement isomer is generated even under a strong alkaline condition, the generation of an impurity II is avoided, the process reproducibility is good, and the method can be smoothly amplified to a kilogram-level reaction scale.

Owner:SHANGHAI ZAIQI BIO TECH

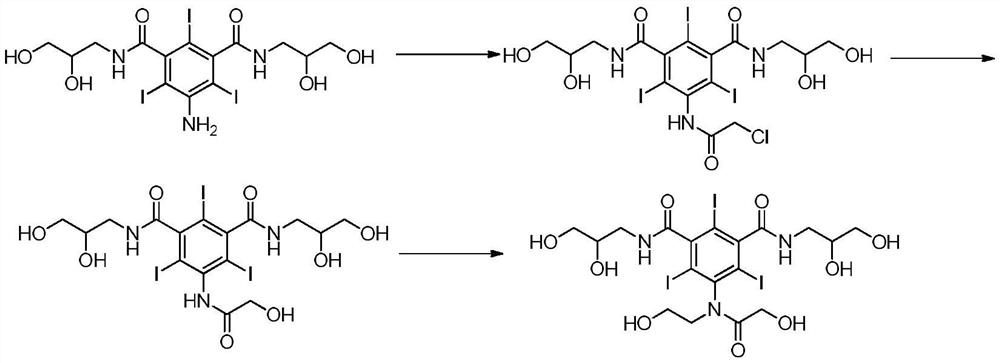

Synthesis method of hydroxyethyl acrylate

PendingCN114656359AReduce yieldLow viscosityOrganic compound preparationCarboxylic acid esters preparationDistillationEthylene glycol toxicity

The present invention relates to the technical field of organic chemical industry, and discloses a hydroxyethyl acrylate synthesis method, which comprises: S1, adding acrylic acid, chloroethanol and sodium hydroxide into a reaction kettle, electrically stirring, uniformly mixing, heating, heating to 120 DEG C, maintaining the constant temperature, heating for 1.5 H, stopping the reaction, and cooling; s2, placing a Buchner funnel at a discharge pipe of the reaction kettle, enabling a solid-liquid mixture to pass through the Buchner funnel, enabling a solid substance to fall above the Buchner funnel, and enabling liquid to flow out of the Buchner funnel to flow into a container below the Buchner funnel; s3, adding quantitative diethylene glycol and a proper amount of hydroquinone into the reaction mother liquor in the container, and carrying out reduced pressure distillation to separate out excessive chloroethanol; the condition of reduced pressure distillation has great influence on the reaction yield, even if a polymerization inhibitor is added, the yield is reduced due to increase of the concentration of chloroethanol in the later stage of distillation, higher temperature, product polymerization and the like, and diethylene glycol with a higher boiling point is added, so that the chloroethanol is diluted in a distillation kettle, the viscosity is reduced, and the temperature is stable and easy to control.

Owner:安徽三禾化学科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Synthesis method of thiodiethylene bis [3-(3, 5-di-tert-butyl-4-hydroxyphenyl) propionate] Synthesis method of thiodiethylene bis [3-(3, 5-di-tert-butyl-4-hydroxyphenyl) propionate]](https://images-eureka.patsnap.com/patent_img/060a5ccc-863b-4a93-8780-23f60355d765/FDA0003448855290000011.png)

![Synthesis method of thiodiethylene bis [3-(3, 5-di-tert-butyl-4-hydroxyphenyl) propionate] Synthesis method of thiodiethylene bis [3-(3, 5-di-tert-butyl-4-hydroxyphenyl) propionate]](https://images-eureka.patsnap.com/patent_img/060a5ccc-863b-4a93-8780-23f60355d765/BDA0003448855300000011.png)

![Synthesis method of thiodiethylene bis [3-(3, 5-di-tert-butyl-4-hydroxyphenyl) propionate] Synthesis method of thiodiethylene bis [3-(3, 5-di-tert-butyl-4-hydroxyphenyl) propionate]](https://images-eureka.patsnap.com/patent_img/060a5ccc-863b-4a93-8780-23f60355d765/BDA0003448855300000021.png)