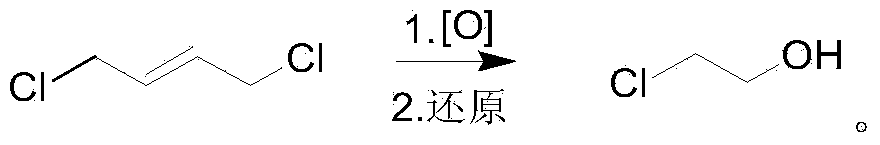

High-purity chlorohydrins and preparation method thereof

A chloroethanol and high-purity technology, applied in the field of preparing high-purity chloroethanol, can solve the problems of serious pollution, high cost of purification process, large energy consumption, etc., and achieve the effects of high yield, low pollution and simple post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 125 grams of 1,4-dichloro-2-butene (1mol) and 200 milliliters of methanol into a 500-mL four-necked flask, mechanically stir at -25°C, and adjust the oxygen flow to carry out the ozonation reaction, followed by gas chromatography React, raw material disappears in about 3 hours, and reaction finishes and stops ozonation. Use nitrogen gas to drive away the ozone in the reaction bottle, keep the inner temperature at about -10°C, add dropwise to 150 ml of methanol solution containing 40.0 g of sodium borohydride (1.05 mol), and continue stirring for 1 hour after the addition. After the reaction is complete, usually The solvent was recovered under pressure, and the fraction at 128-129°C was collected by atmospheric distillation to obtain 136.8 g of a colorless transparent liquid with a gas phase content of 99.4% and a yield of 84.5%.

[0023] Product structure confirmation:

[0024] 1 HNMR (δppm, 400MHz, CDCl 3 ):3.60-3.74(m,2H,-CH 2 Cl);3.82-3.96(m,2H,-CH* 2 OH); 2...

Embodiment 2

[0027] Add 125 grams of 1,4-dichloro-2-butene (1mol) and 200 milliliters of ethanol into a 500-mL four-necked flask, stir mechanically at -10°C, and carry out ozonation reaction after adjusting the oxygen flow, followed by gas chromatography React, raw material disappears in about 3 hours, and reaction finishes and stops ozonation. Pass nitrogen to drive away the ozone in the reaction bottle, keep the inner temperature around 0°C, add dropwise to 150 ml ethanol solution containing 66.0 g potassium borohydride (1.2 mol), continue to stir and react for 1.5 hours after the addition, the reaction is completed, and the normal pressure The solvent was recovered, and the fraction at 128-129°C was collected by atmospheric distillation to obtain 140.3 g of a colorless transparent liquid with a gas phase content of 99.7% and a yield of 86.9%. Product nuclear magnetic spectrum is identical with embodiment 1.

Embodiment 3

[0029] Add 125 grams of 1,4-dichloro-2-butene (1mol) and 200 milliliters of isopropanol into a 500-mL four-neck flask, mechanically stir at 5°C, and adjust the oxygen flow to carry out the ozonation reaction. Gas chromatography Following the reaction, the raw materials disappeared in about 3 hours, and the ozonation was stopped at the end of the reaction. Pass nitrogen to drive off the ozone in the reaction bottle, keep the inner temperature at about 10°C, add dropwise to 150 ml of ethanol solution containing 50.0 g of potassium borohydride (0.91 mol), continue to stir and react for 2 hours after the addition, the reaction is completed, and the normal pressure The solvent was recovered, and the fraction at 128-129°C was collected by atmospheric distillation to obtain 138.7 g of a colorless transparent liquid with a gas phase content of 99.5% and a yield of 85.7%. Product nuclear magnetic spectrum is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com