Wind generating set blade root bolt fracture monitoring method

A technology for wind turbines and bolts, which is applied to the monitoring of wind turbines, wind turbines, motors, etc., can solve the problems of high construction time and cost, complex process, bolt breakage, etc., to ensure safe and reliable operation, simple process and reliability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with drawings and embodiments.

[0043] The invention provides a method for monitoring the fracture of blade root bolts of a wind power generating set, referring to Figure 1 to Figure 9 , including the following procedures:

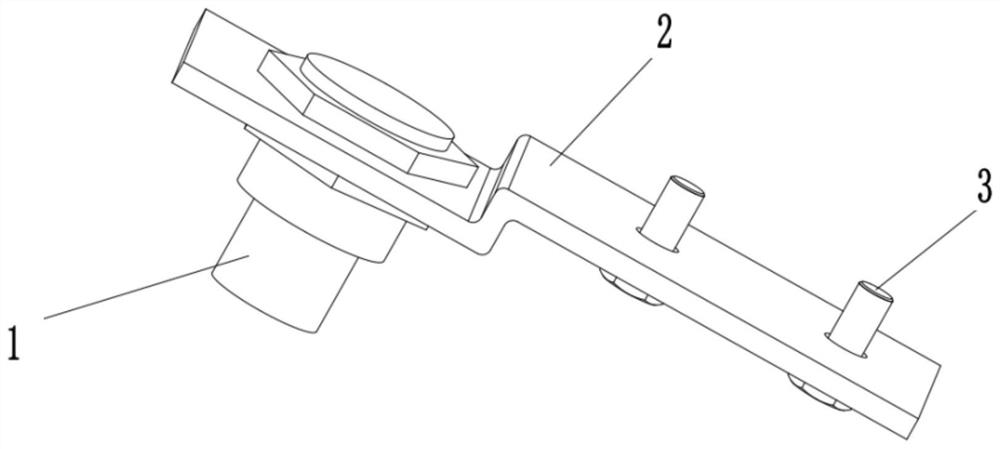

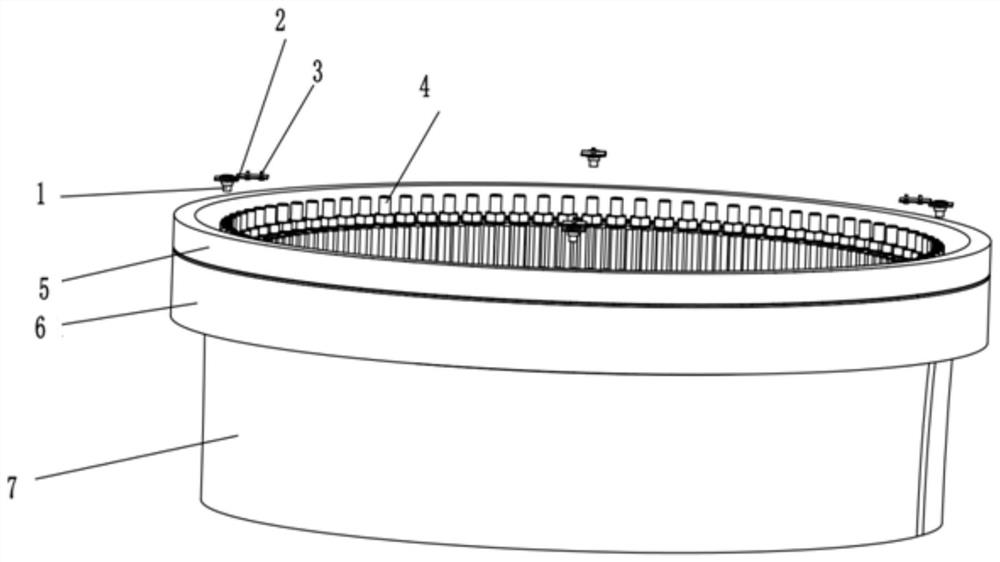

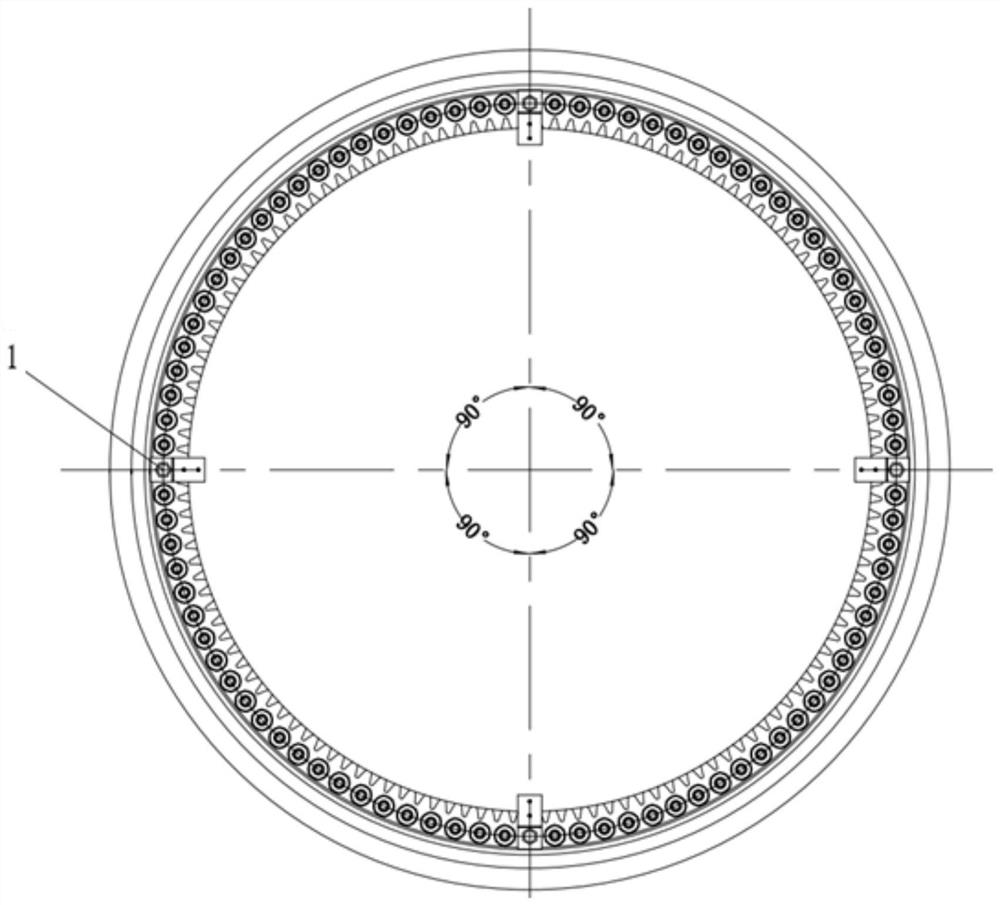

[0044] (1) The blade root of the wind turbine includes the blade root main body 7, the blade root slewing bearing 6 and the hub 5, and the hub web 8 is arranged inside the hub, and a group of high-precision ranging sensors 1 are installed on the hub web to measure The number of distance sensors is n, and the high-precision distance-measuring sensors are evenly distributed in the circumferential direction with the center of the hub web as the center, and the probes of the high-precision distance-measuring sensors point to the end face of the blade root bolt 4;

[0045] (2) Measure and obtain the following reference values when the blade root bolts are in normal condition:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com