Beef processing water removing equipment

A beef and equipment technology, applied in the field of beef processing water removal equipment, can solve the problems that beef cannot be removed, production quality is affected, and the water content of beef cannot be measured.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

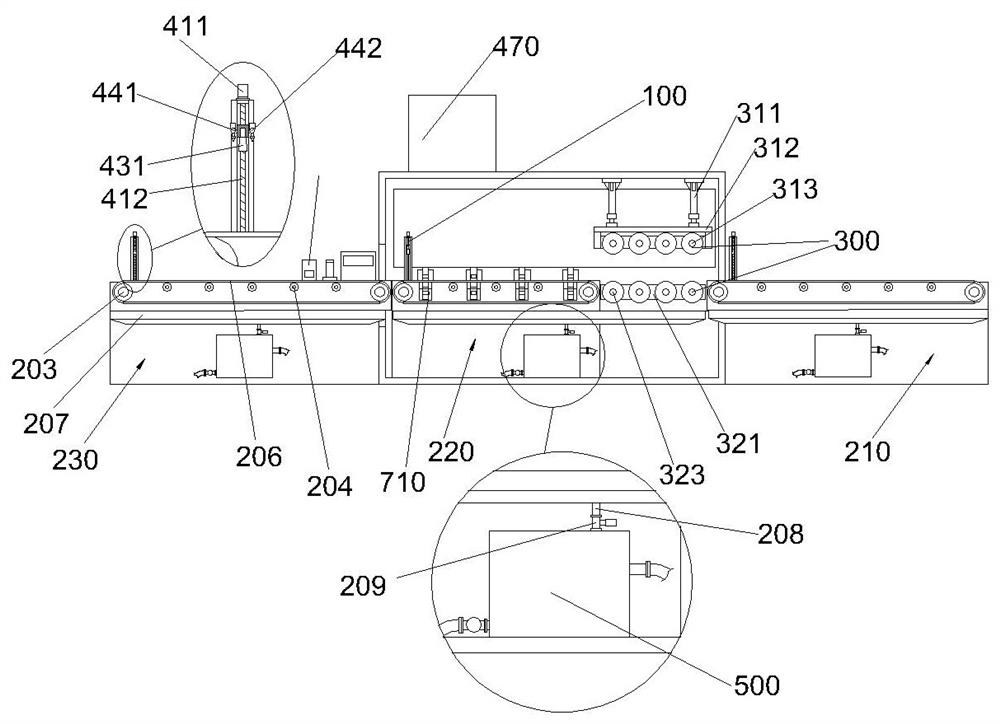

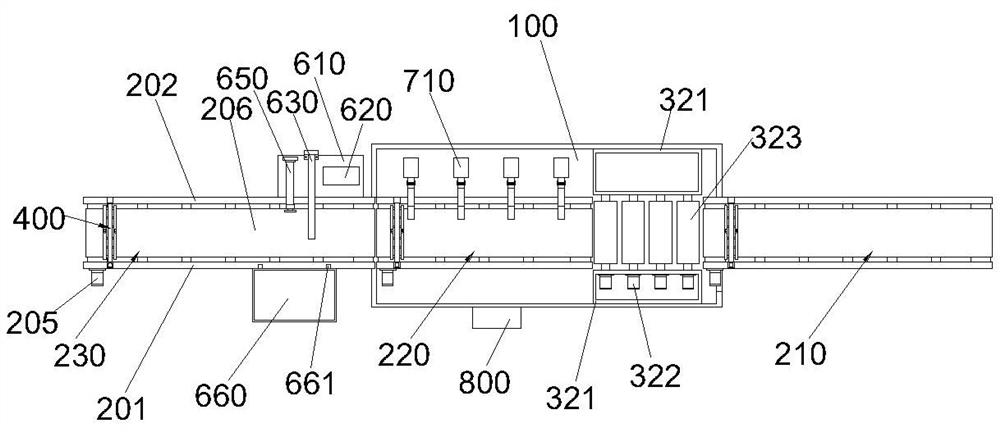

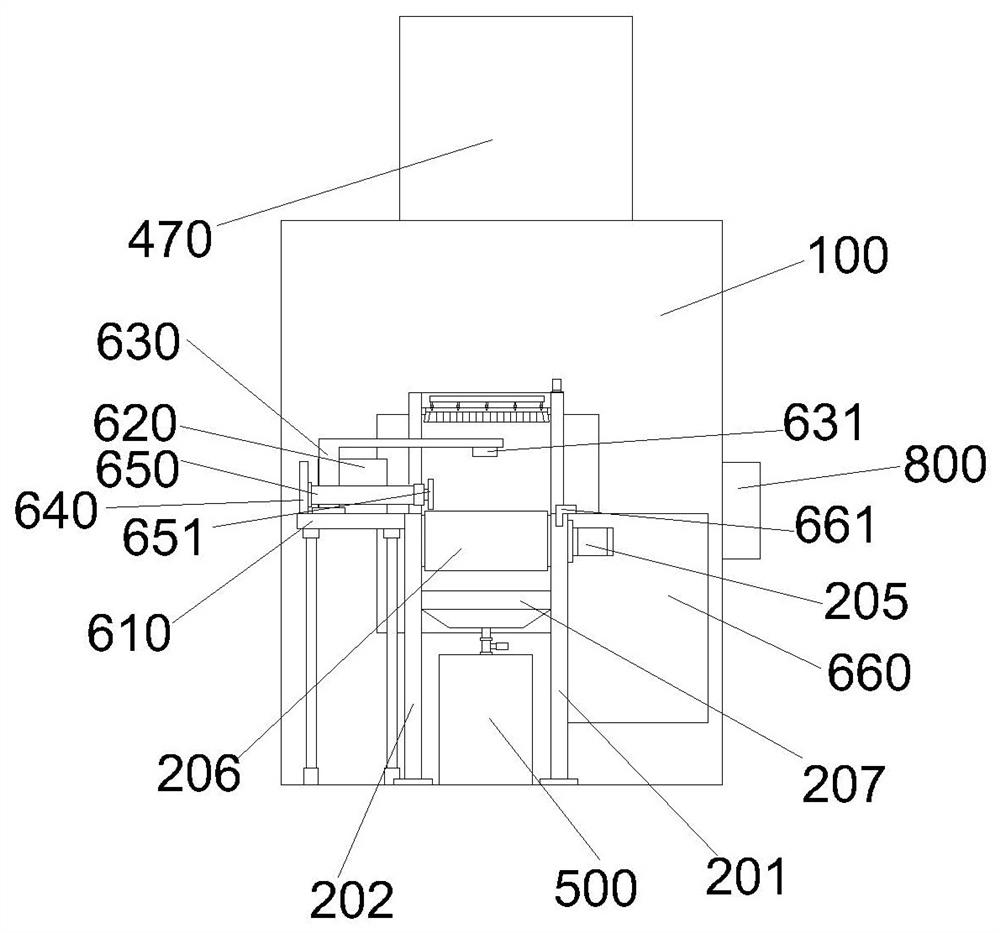

[0034] see Figure 1-Figure 8 , the present invention provides the following technical solutions: a beef processing dewatering equipment, including a dewatering device warehouse 100, a first conveying device 210 is installed on the right side of the dewatering device warehouse 100, and the inside of the dewatering device warehouse 100 Squeeze roller device 300 and second conveying device 220 are installed, and the left side of described dewatering device storehouse 100 is installed with the 3rd conveying device 230, and described first conveying device 210, described second conveying device 220 and described The top of the third conveying device 230 is equipped with a conveyor belt cleaning device 400, and the bottoms of the first conveying device 210, the second conveying device 220 and the third conveying device 230 are all provided with an oil-water collecting and separating device 500, so A moisture detection and removal device is installed on the rear side of the third co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com