Environment-friendly geopolymer battery and preparation method thereof

A geopolymer and environmental protection technology, applied in the field of environmentally friendly geopolymer batteries and its preparation, can solve the problems of high recovery rate of disposable battery recycling cost, enterprises' reluctance to recycle and dispose, battery loss, etc., and achieve good mechanical integrity , High metal utilization rate, high discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] This technical solution also proposes a preparation method of an environmentally friendly geopolymer battery, which is used for the above-mentioned environmentally friendly geopolymer battery, including the following steps:

[0069] (1) Mixing granulated blast furnace slag and fly ash according to the ratio to obtain geopolymer powder;

[0070] (2) Stir the geopolymer powder and the potassium-based base activator according to the proportioning ratio, add manganese dioxide powder and graphite powder in the stirred geopolymer powder and the potassium-based base activator and stir again to obtain positive Electrode mixture;

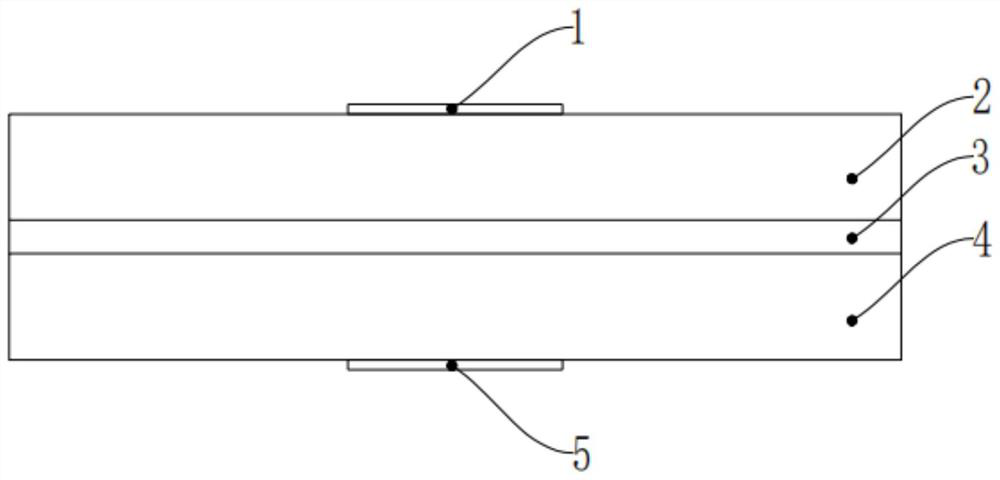

[0071] (3) placing the first metal patch on the bottom of the mold, pouring the positive electrode mixture into the mold, and forming the positive electrode layer 2 after curing;

[0072] (4) Stir the geopolymer powder and the potassium-based base activator according to the proportioning ratio to obtain the electrolyte mixture;

[0073] (5) pouring ...

Embodiment 1

[0078] Embodiment 1 - a kind of preparation method of environment-friendly geopolymer battery

[0079] (1) 5 parts of S105 grade granulated blast furnace slag and 2 parts of fly ash are mixed to obtain geopolymer powder;

[0080] (2) 40 parts of geopolymer powder and 20 parts of potassium silicate aqueous solution with a modulus of 2.0 and a concentration of 48% were stirred for 1 min at a speed of 700 r / min, and the stirred geopolymer powder and silicic acid Add 15 parts of 300-mesh electrolytic manganese dioxide powder and 2 parts of 3000-mesh graphite powder into the potassium aqueous solution and stir for 1 min at a speed of 700 r / min to obtain a positive electrode mixture;

[0081] (3) Place the first metal patch with a size of 20mm*20mm and a resistivity of 0.1μΩ*m at the bottom of a mold with a length of 4cm and a width of 1cm, pour the positive electrode mixture into the mold, let it stand for 2min, and then solidify to form A positive electrode layer 2 with a thickne...

Embodiment 2

[0086] Embodiment 2 - a kind of preparation method of environment-friendly geopolymer battery

[0087] (1) Mix 6 parts of S105 grade granulated blast furnace slag and 3 parts of fly ash to obtain geopolymer powder;

[0088](2) 45 parts of geopolymer powder and 20 parts of potassium silicate aqueous solution with a modulus of 2.1 and a concentration of 50% were stirred for 1 min at a speed of 850 r / min, and the stirred geopolymer powder and silicic acid Add 20 parts of 350-mesh electrolytic manganese dioxide powder and 3 parts of 4000-mesh graphite powder into the potassium aqueous solution and stir for 1 min at a speed of 850 r / min to obtain a positive electrode mixture;

[0089] (3) Place the first metal patch with a size of 20mm*20mm and a resistivity of 0.05μΩ*m at the bottom of a mold with a length of 5cm and a width of 2cm, pour the positive electrode mixture into the mold, and let it stand for 2 minutes to solidify and form A positive electrode layer 2 with a thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com