System and method for adjusting effective electromechanical coupling coefficient of ultrahigh-frequency bulk acoustic wave resonator

A bulk acoustic wave resonator, electromechanical coupling technology, applied in the direction of electrical components, impedance networks, etc., can solve the problems of large effective electromechanical coupling coefficient, excessive electromechanical coupling coefficient, large relative bandwidth of the filter, etc., to reduce the effective electromechanical coupling coefficient , weaken the effect of the piezoelectric effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]The technical solutions in the embodiments of the present invention will be described below in conjunction with the embodiments of the present invention, and clearly, the described embodiments are merely embodiments of the invention, not all of the embodiments. Based on the embodiments in the present invention, all other embodiments obtained in the art without creative labor are not made in the premise of creative labor.

[0022]It should be noted that the features in the present invention in the present invention can be combined with each other in the case of an unable conflict.

[0023]The present invention will be further described below in connection with the specific embodiments, but is not limited as the present invention.

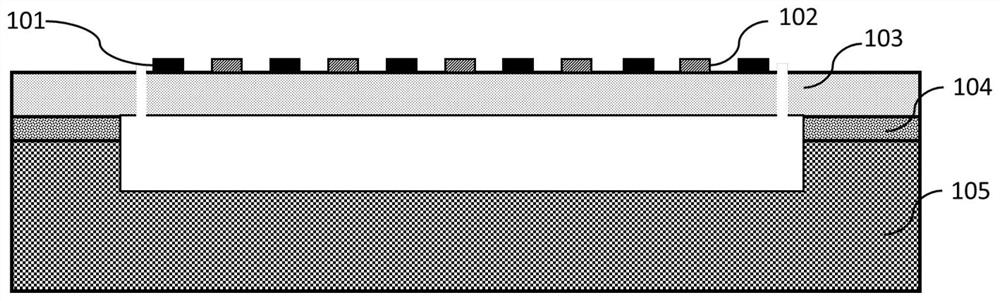

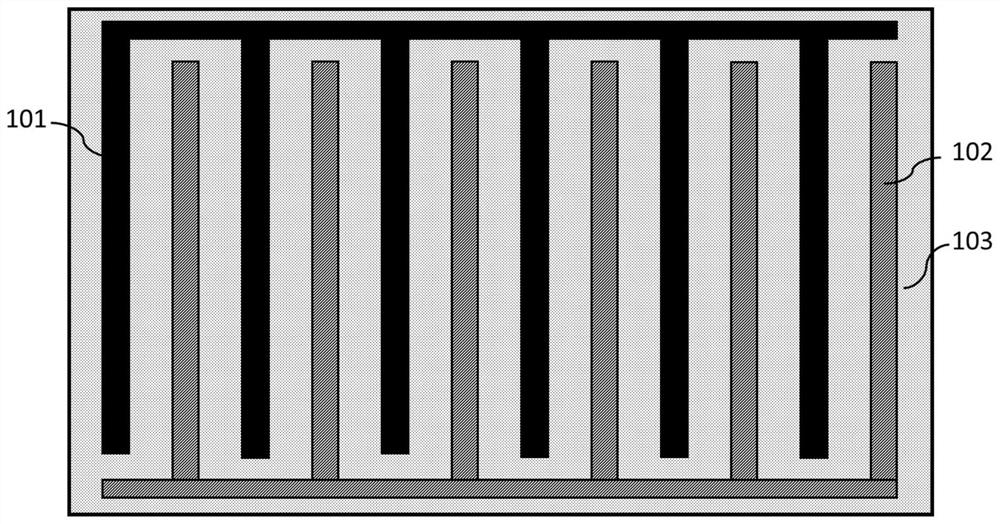

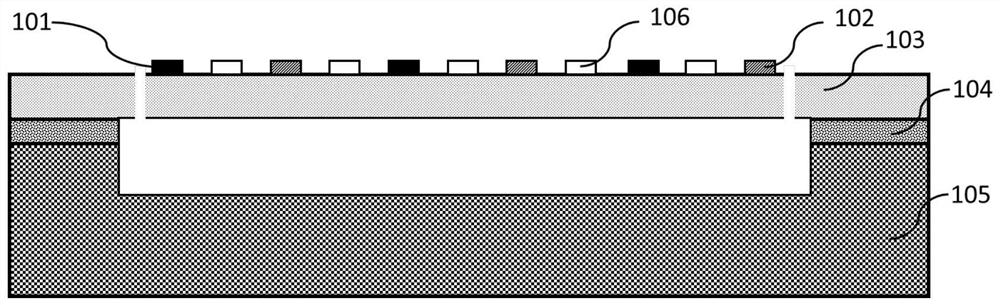

[0024]The method of adjusting the effective electromechanical coupling coefficient of the ultra-high frequency acoustic resonator is suitable for reducing the system of efficient electromechanical coupling coefficient of ultra high frequency acoustic resonato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com