Ecological restoration method for high and steep slope

A technology for high and steep slopes and ecological restoration, applied in botany equipment and methods, excavation, lawn growth, etc., can solve problems such as slope water and soil loss, unsuitable for vegetation growth, etc., achieve high water storage rate, porous structure water retention The effect of high resistance and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

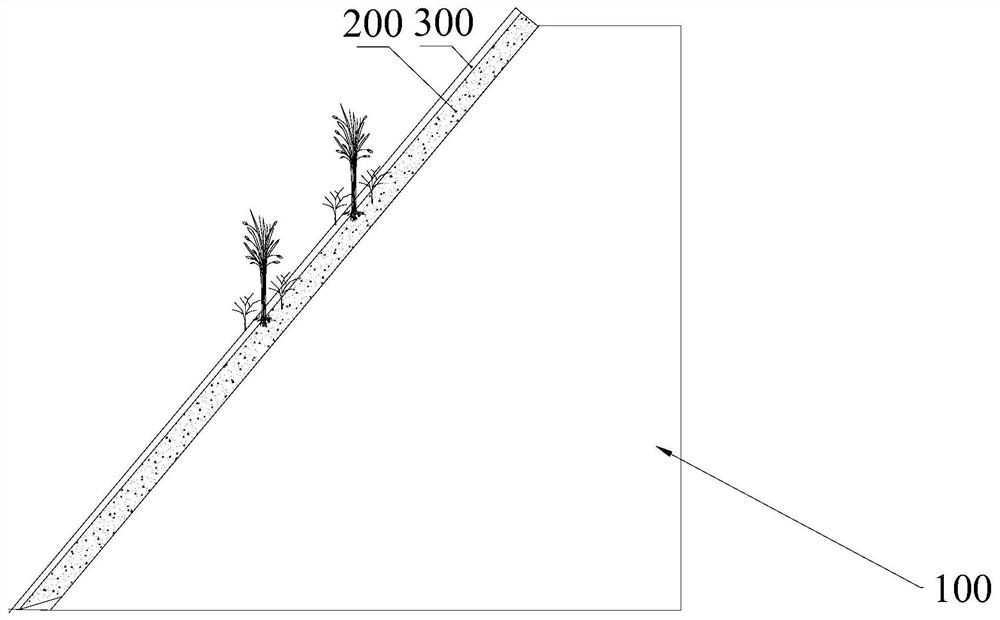

[0056]Such asfigure 1 As shown, an ecological repair method of a high steep slope, a first nutrient group and a second nutrient group in a high steep slope 100, and the first nutrient group forms a first matrix layer 200 in contact with the high steep slope 100. The second nutrient group forms a second matrix layer 300 located above the first matrix layer 200, and the thickness of the first matrix layer is 3 to 5 times the thickness of the second matrix layer.

[0057]When actual use, the first nutrient group is based on mass, including the following raw materials:

[0058]2.5 to 9.5 parts of the mine sector or tail sand

[0059]7.5-8.5 parts of larcoal or humic acid organic fertilizer;

[0060]3.5 ~ 4.5 parts of plant fibers;

[0061]Soil microatic state improvement liquid 0.18 ~ 0.22;

[0062]2.04 ~ 0.06 parts of sustained release compound fertilizer;

[0063]Low alkaline sulfur salt cement 1.8 ~ 2.2 parts;

[0064]0.18 ~ 0.22 sulfur powder;

[0065]0.18 ~ 0.22 polyvinyl alcohol;

[0066]1.8 ~ 2.2.2 parts of a...

Embodiment 2

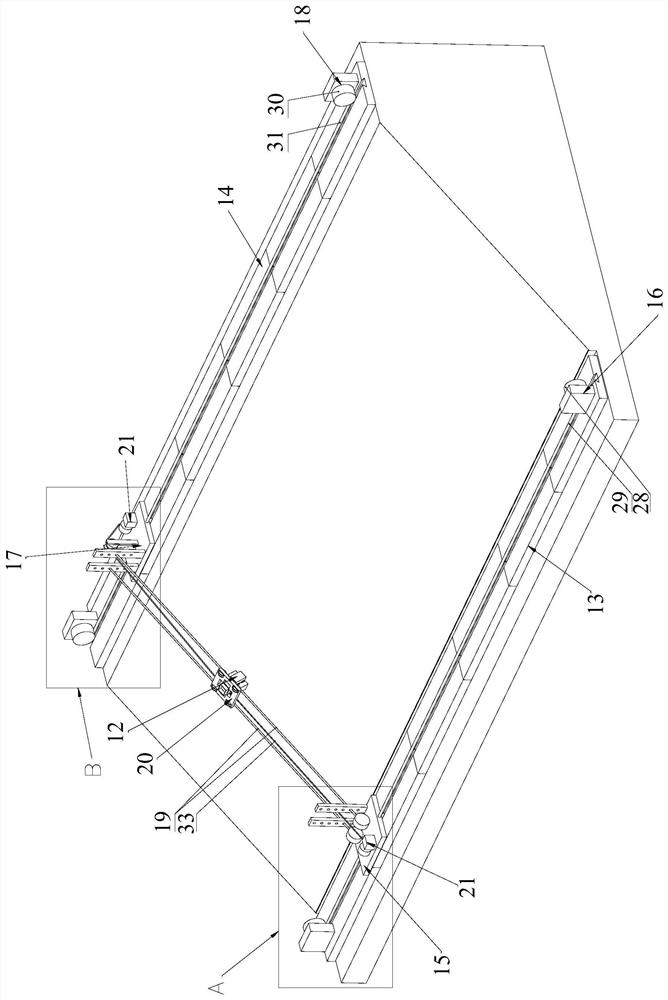

[0097]Such asFigure 2 ~ 7As shown, the present embodiment discloses an ejection apparatus planted with a nutrient group, which can be used in Example 1, and the injection device comprises:

[0098]The first profile 13 is used to lay on the bottom of the slope;

[0099]Second profile 14 for laying on the top;

[0100]The base 15 is slid on the first profile 13;

[0101]The first drive mechanism 16 is disposed on the first profile 13 for driving the base 15;

[0102]The top seat 17 is slid on the second profile 14;

[0103]The second drive mechanism 18 is disposed on the second profile 14 for driving the length of the top seat 17, and the top seat 17 is synchronized with the base 15;

[0104]Two parallel wire rope 19, one end of the two wire rope 19 is relatively fixed with the base 15, and the other end is relatively fixed with the top seat 17;

[0105]The mobile seat 20, which is set to two wire rope 19;

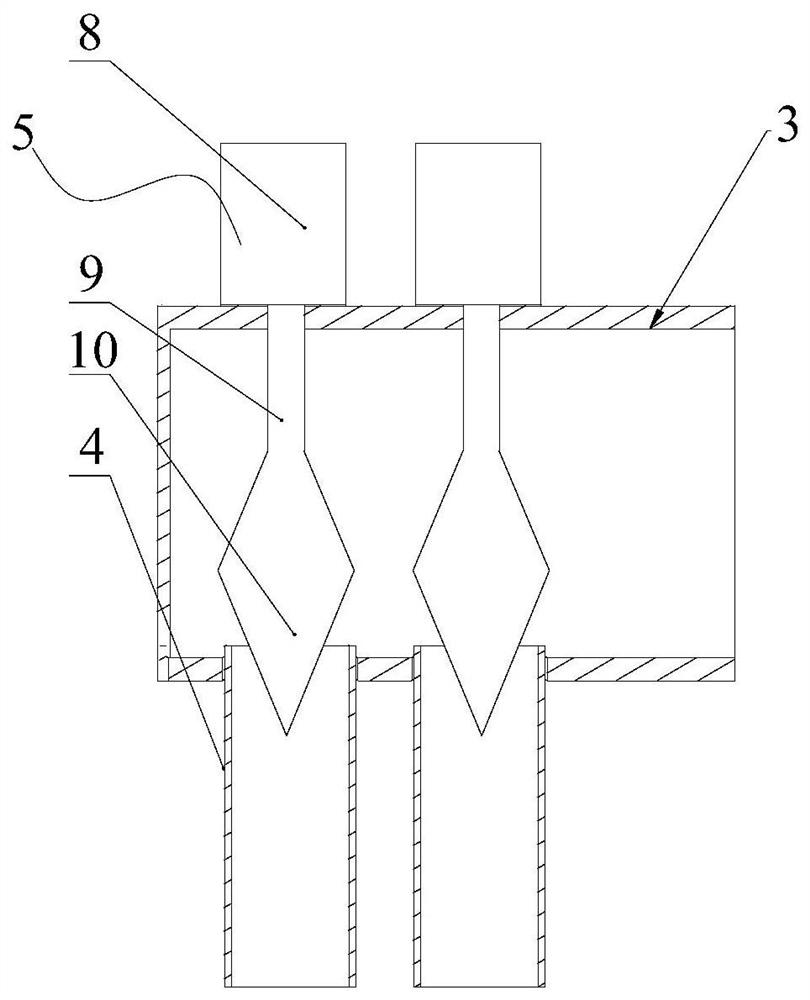

[0106]The injection head is fixed to the moving seat 20, the ejecting head is a multi-port injection hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com