Enzyme hawthorn juice and preparation method thereof

A technology for hawthorn juice and hawthorn concentrated juice, which is applied in the field of beverages, can solve the problem of high added amount of sugar components, and achieve the effects of increasing nutrients, enhancing consistency and stability, and promoting the absorption of nutrients by the human body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

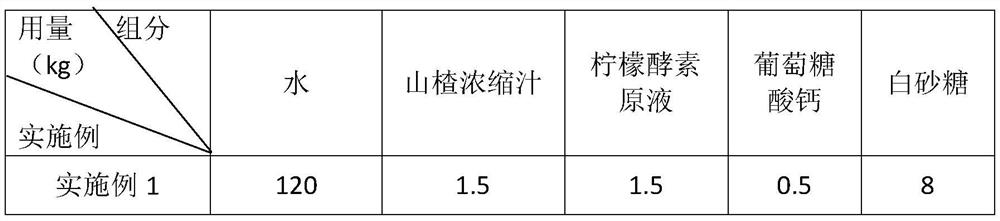

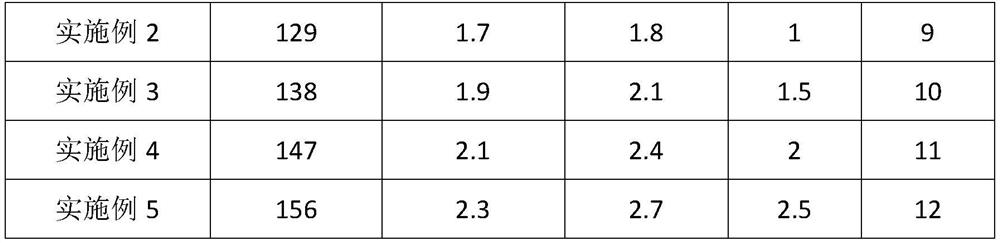

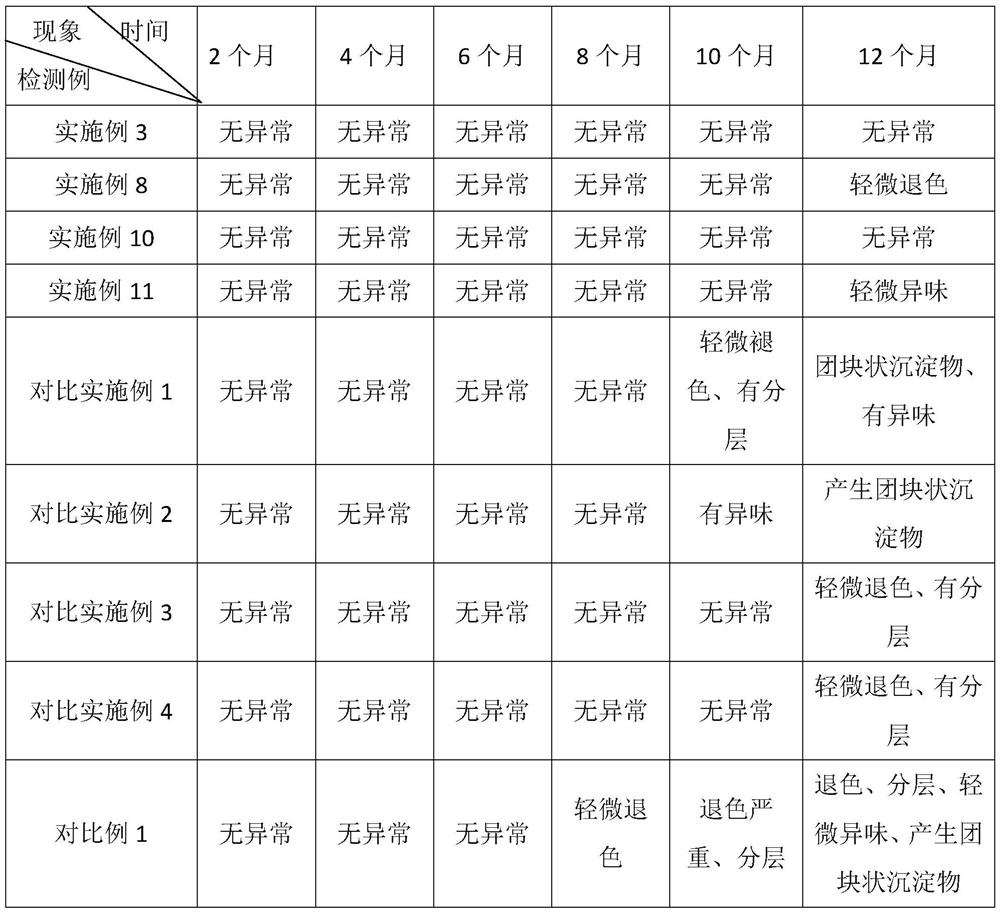

Examples

preparation example 1

[0048] The preparation method of the concentrated hawthorn juice is as follows: 1) artificially select fresh hawthorns free from diseases, insect pests and overripe mildew as raw materials, wash and dry;

[0049]2) After the hawthorn fruit is crushed, add water twice the weight of the hawthorn fruit, heat up to about 100°C for 10 minutes to soften, cool down and keep at about 60°C for 4 hours, and obtain the hawthorn slurry;

[0050] 3) Centrifuge the hawthorn slurry for 20 minutes at a rotating speed of 1500r / min for 20 minutes after coarse filtration to obtain a centrifuge, which is divided into a centrifuge A and a centrifuge B, and the weight ratio of the centrifuge A to the centrifuge B is 2:1;

[0051] 4) Adsorb the centrate B in 3) with the D382 type resin activated by 1mol / L NaOH solution to obtain the treatment solution B;

[0052] 5) Concentrate the centrifuge solution A in vacuum until the soluble solids reach 70wt% at a vacuum degree of 0.08MPa to obtain hawthorn j...

preparation example 2

[0055] The preparation method of the concentrated hawthorn juice is as follows: 1) artificially select fresh hawthorns free from diseases, insect pests and overripe mildew as raw materials, wash and dry;

[0056] 2) After the hawthorn fruit is crushed, add water twice the weight of the hawthorn fruit, heat up to about 100°C for 10 minutes to soften, cool down and keep at about 60°C for 4 hours, and obtain the hawthorn slurry;

[0057] 3) Centrifuge the hawthorn pulp for 20 minutes at a rotating speed of 1500r / min after coarse filtration to obtain a centrifuge, which is divided into a centrifuge A and a centrifuge B, and the weight ratio of the centrifuge A to the centrifuge B is 3:1;

[0058] 4) Adsorb the centrate B in 3) with the D301G type resin activated by 1mol / L NaOH solution to obtain the treatment solution B;

[0059] 5) Concentrate the centrifuge solution A in vacuum until the soluble solids reach 70wt% at a vacuum degree of 0.08MPa to obtain hawthorn juice slurry;

...

preparation example 3

[0062] The preparation method of the concentrated hawthorn juice is as follows: 1) artificially select fresh hawthorns free from diseases, insect pests and overripe mildew as raw materials, wash and dry;

[0063] 2) After the hawthorn fruit is crushed, add water twice the weight of the hawthorn fruit, heat up to about 100°C for 10 minutes to soften, cool down and keep at about 60°C for 4 hours, and obtain the hawthorn slurry;

[0064] 3) Centrifuge the hawthorn pulp for 20 minutes at a rotating speed of 1500r / min after coarse filtration to obtain a centrifuge, which is divided into a centrifuge A and a centrifuge B, and the weight ratio of the centrifuge A to the centrifuge B is 3:1;

[0065] 4) Adsorb the centrate B in 3) with the L-300 type resin activated by 1mol / L NaOH solution to obtain the treatment solution B;

[0066] 5) Concentrate the centrifuge solution A in vacuum until the soluble solids reach 70wt% at a vacuum degree of 0.08MPa to obtain hawthorn juice slurry;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com