Moisturizing mask and preparation process thereof

A preparation process and wet face technology, applied in the field of moisturizing facial mask and its preparation, can solve the problem that the creamy facial mask cannot be cut into sheets and integrated into one body and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

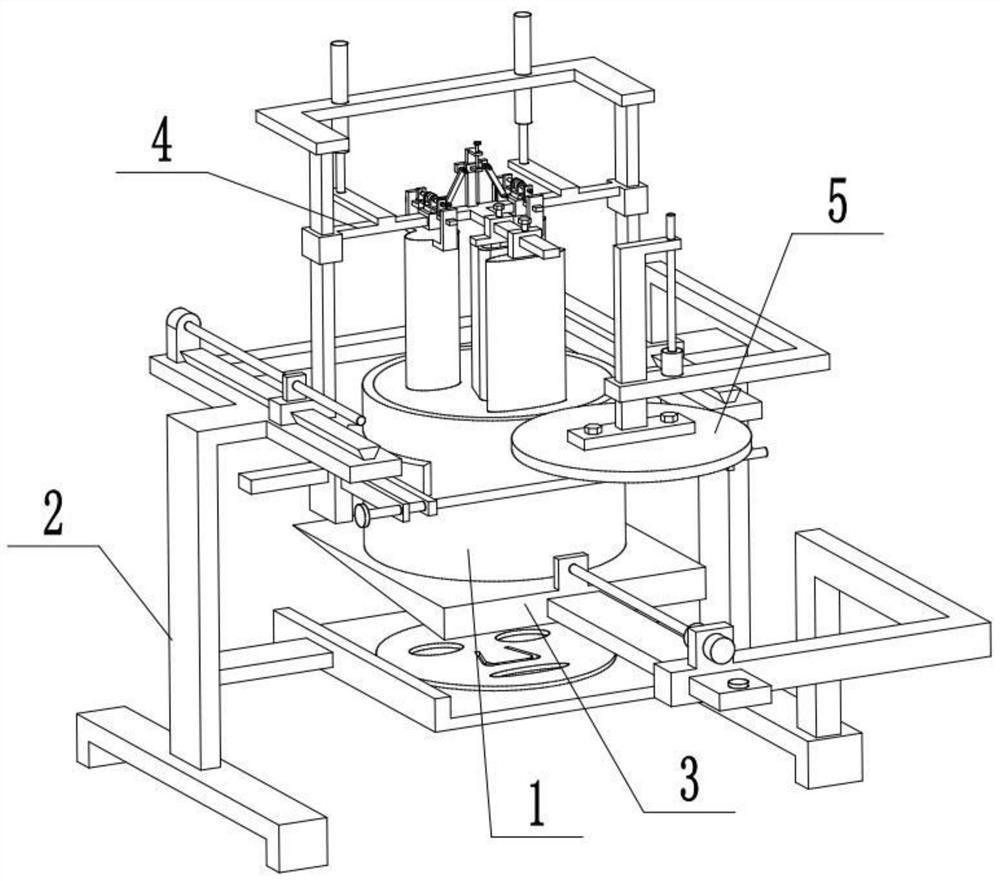

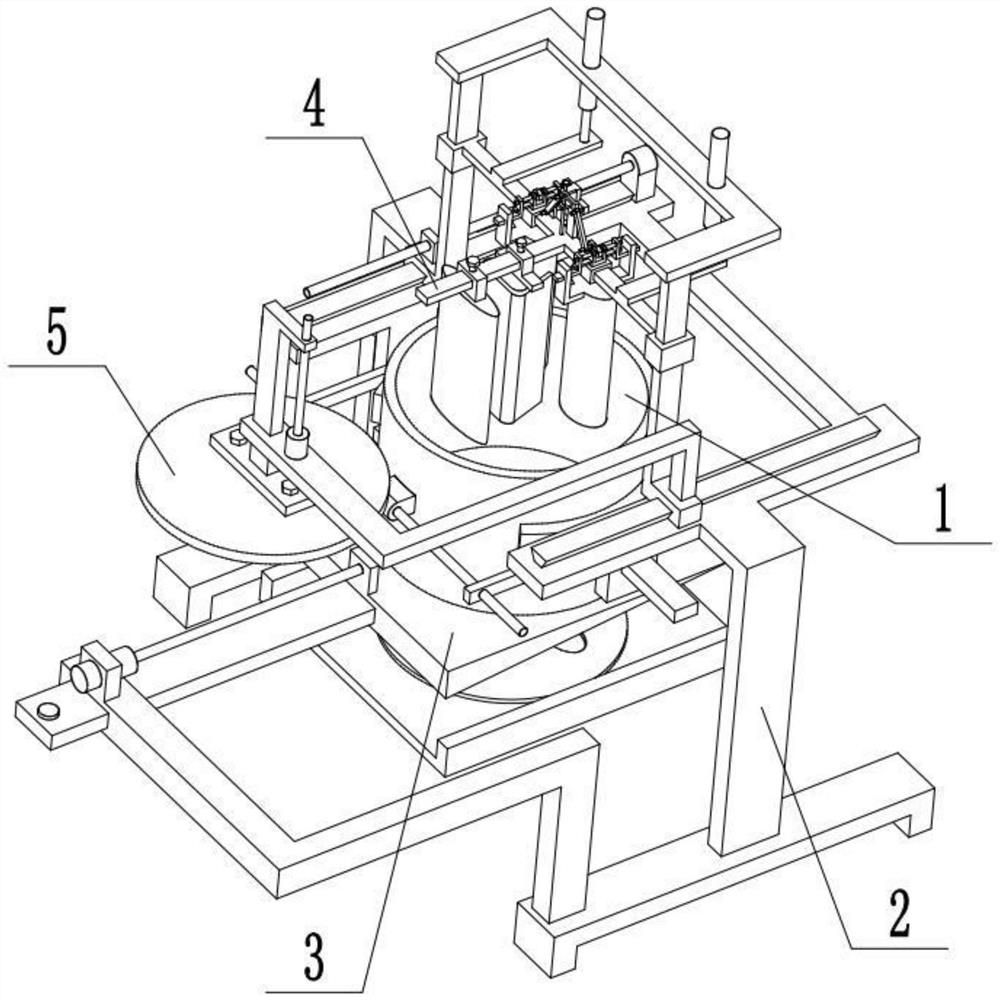

[0038] Combine below Figure 1-10 Illustrate this embodiment mode, a kind of moisturizing facial mask preparation process, comprises the following steps:

[0039] Step 1. Add the solid moisturizing mask paste into the circular mold;

[0040] Step 2, place a piece of non-woven facial mask paper at the lower end of the circular mold;

[0041] Step 3. Form the moisturizing mask paste into sheets;

[0042] Step 4, the sheet-shaped circular mask paste falls on the non-woven mask paper to form a whole;

[0043] The above-mentioned moisturizing mask preparation process also involves a moisturizing mask preparation device;

[0044]The preparation device of the moisturizing facial mask comprises a bucket 1, a fixed frame 2, a placement frame 2-1, a plane cutter 3, a plate 3-1, a shelf plate 3-2, a motor two 3-3 and a lead screw three 3-4 , the material barrel 1 is arranged on the fixed frame 2, and the fixed frame 2 is fixedly connected with the placement frame 2-1, and the placeme...

specific Embodiment approach 2

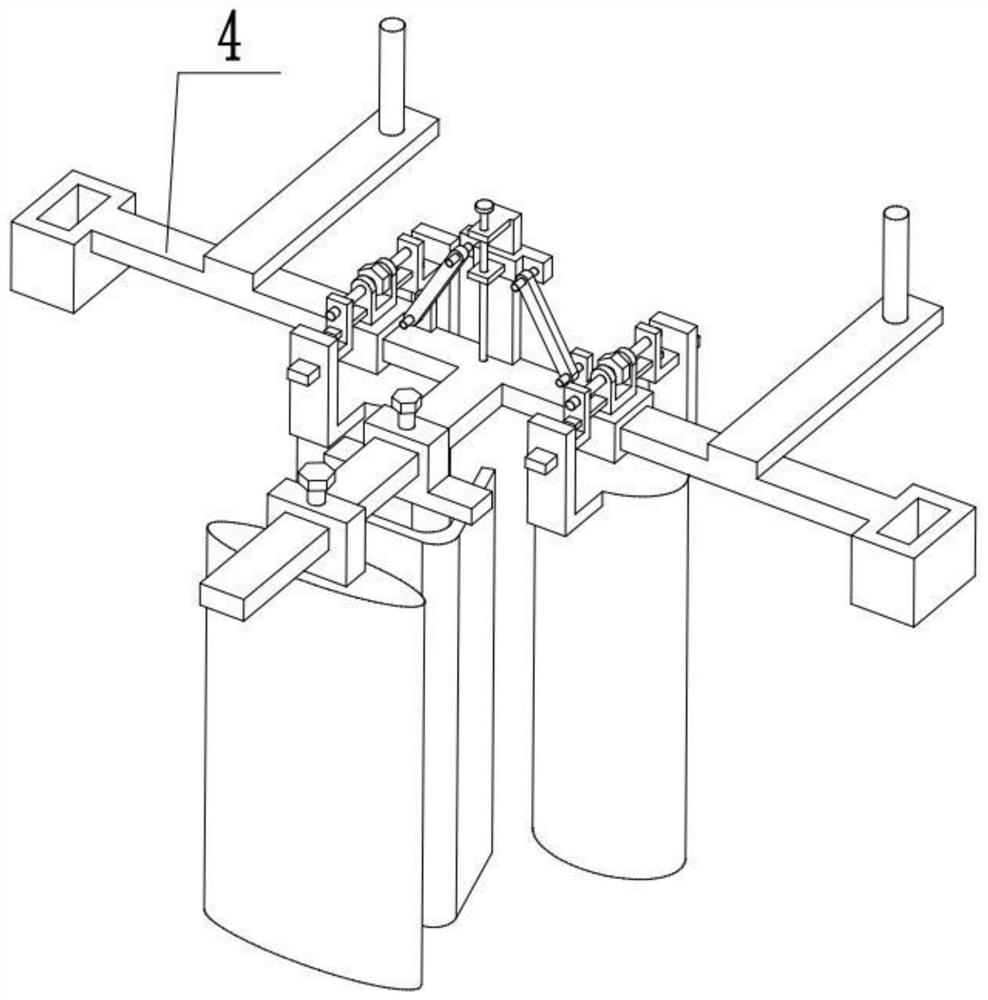

[0046] Combine below Figure 1-10 Illustrate the present embodiment, described moisturizing facial mask preparation device also comprises vertical bar 2-3, top board 2-6, oil tank one 2-7, T frame 4, back board 4-1, front board 4-5, nose mold 4-6, the mouth mold 4-7 and the eye mold 4-8, the two ends of the top plate 2-6 are respectively fixedly connected with a vertical rod 2-3, and the two vertical rods 2-3 are all arranged on the fixed frame 2, The two ends of the T-shaped frame 4 are respectively slidably connected to the two vertical rods 2-3 through a square sleeve, and the top plate 2-6 is fixedly connected to two oil cylinders 2-7, and the telescopic ends of the two oil cylinders 2-7 are respectively Fixedly connected on the two back plates 4-1, the two back plates 4-1 are all fixedly connected on the T-shaped frame 4, and the T-shaped frame 4 is symmetrically provided with two eye molds 4-8, and the front plate 4- 5 is fixedly connected to the middle part of the T-sh...

specific Embodiment approach 3

[0048] Combine below Figure 1-10 Illustrate the present embodiment, described moisturizing facial mask preparation device also comprises groove block 4-2, long screw 4-3, hinge rod 4-4 and slide sleeve 4-12, and groove block 4-2 is slidably connected in the middle part of T frame 4 , the groove block 4-2 is threadedly connected with the long screw 4-3, and the long screw 4-3 is rotatably connected to the upper end of the T-shaped frame 4, and the two ends of the groove block 4-2 are respectively rotatably connected to a hinge rod 4-4, two The articulated rod 4-4 is rotatably connected to two sliding sleeves 4-12 respectively, and the two sliding sleeves 4-12 are respectively slidably connected to the two ends of the T-shaped frame 4, and the two eye molds 4-8 are respectively arranged on two On the sliding sleeve 4-12. Turning the long screw 4-3 drives the groove block 4-2 to move up and down, and the groove block 4-2 passes through the hinge rod 4-4 to drive the two eye mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com