Desalting reverse osmosis process and water treatment system

A technology of reverse osmosis water and treatment system, applied in the field of water treatment, can solve the problems of low reverse osmosis efficiency, large impact force of membrane, slow flow speed, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

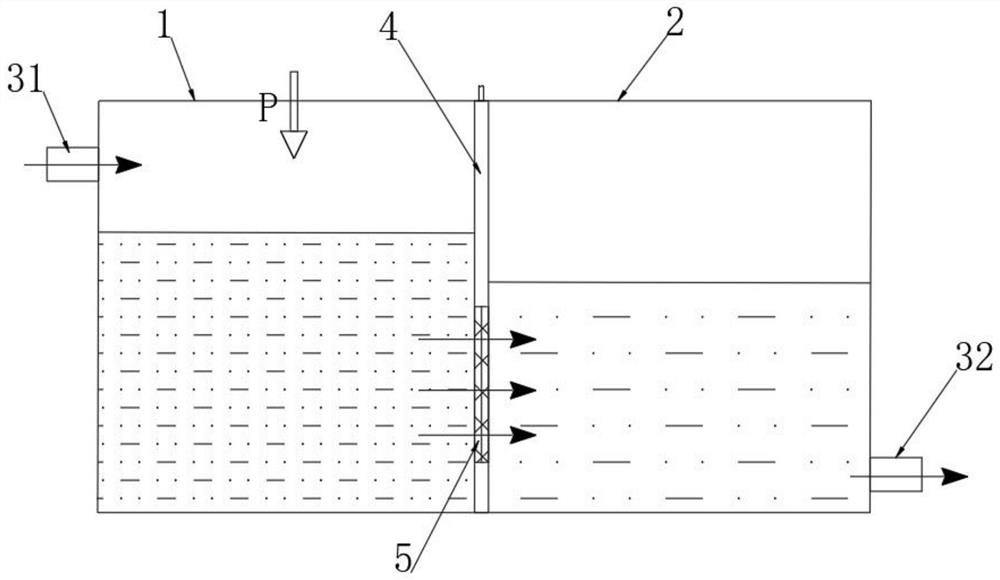

[0045]Seefigure 1 A soiled of the salt reverse osmosis water treatment system, including the reverse osmix box 1 and the water storage tank 2, the reverse osmoxifier 4 is fixed between the gas separator 4, and the reverse binding box 1 is fixed to the upper left upper end. The water supply pipe 31 of the pressurized pump is fixedly connected to the bottom right of the upper right lower end, and the lower end of the ventilation separator 4 is mounted, and the reverse osmosis assembly 5 is mounted in the mounting hole.

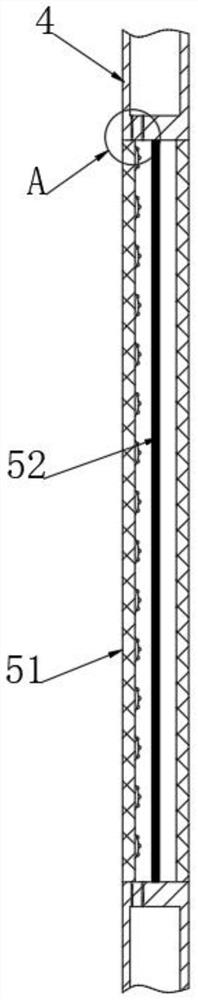

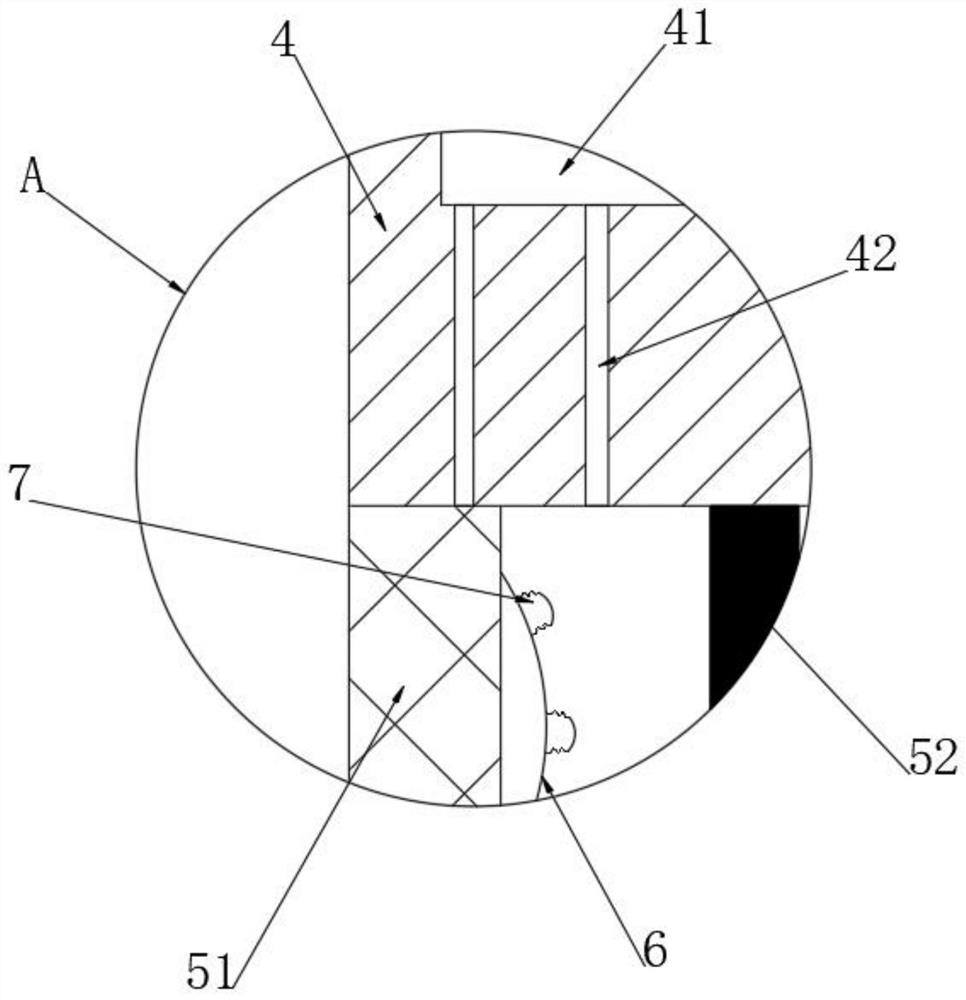

[0046]SeeFigure 2-3 The interior of the ventilation plate 4 has a bidirectional cavity, and the upper end of the ventilation separator 4 is fixedly connected, and the bidirectional cavity is connected to the outside air source, and the bidirectional cavity includes 41 and two 42, and two 42, The 41 and 42 are excluded in the ventilation separator 4, and the reverse osmosis assembly 5 includes two pneumatic flushing nets 51 and reverse osmosis membrane 52, and the reverse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com