Magnetic suction type treatment process for oil-containing industrial wastewater

A technology of industrial wastewater and treatment process, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, magnetic field/electric field water/sewage treatment, etc. The application of industrial wastewater, the inability to separate oil droplets, etc., achieve the effects of low cost, overall weight reduction, and full recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

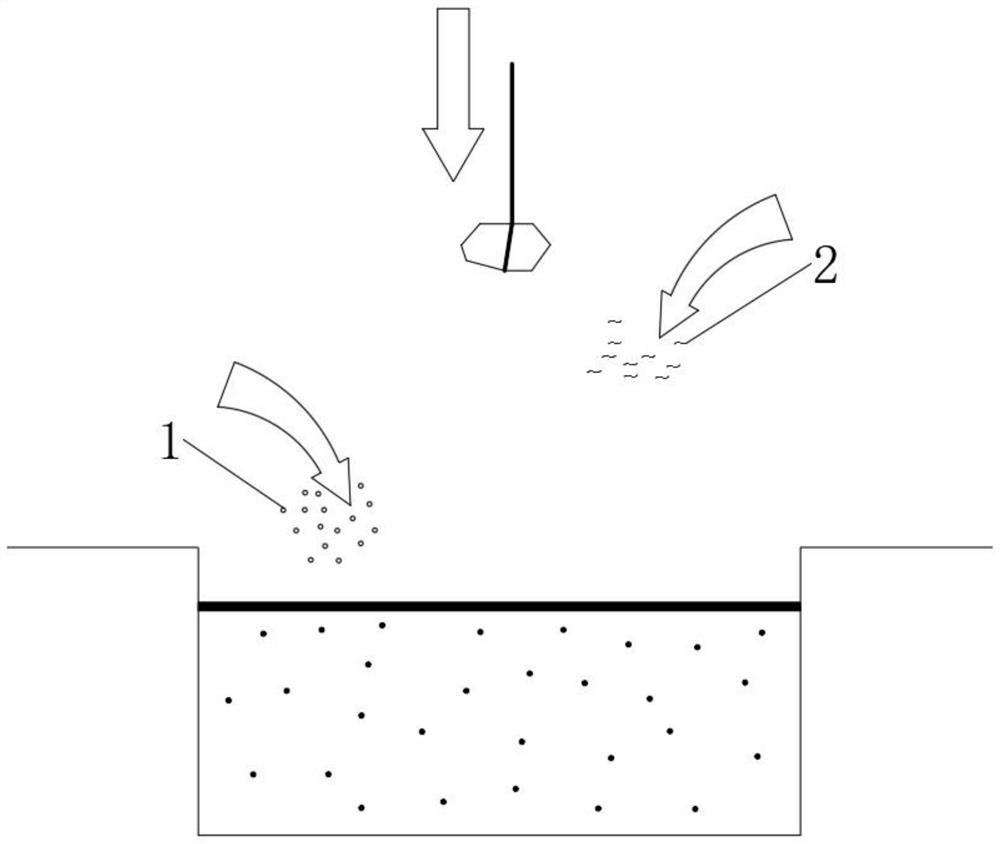

[0048] see figure 1 , a magnetic treatment process for oily industrial wastewater, comprising the following steps:

[0049] S1. Perform primary filtration on the generated industrial waste water and discharge it into the reservoir for static stratification;

[0050] S2. Put the magnetized microspheres 1 evenly into the reservoir in the upper direction, and the magnetized microspheres 1 sink in the waste water and trigger the dissolution phenomenon after touching the oil droplets mixed in the waste water, so as to realize the suspended stay;

[0051] S3. Put the oil-seeking fiber rod 2 evenly into the reservoir, and the oil-seeking fiber rod 2 will actively approach and "find" the oil droplets wrapped with the magnetic microspheres 1 during the sinking process in the wastewater, and then absorb and finally sink into the water. the bottom of the pool;

[0052] S4. Recover the magnetized microsphere 1 and the oil-seeking fiber rod 2 by hanging the magnet into the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com