Sea-island fiber for thermoformed non-woven fabric and preparation method of sea-island fiber

A sea-island fiber and non-woven fabric technology, which is applied in stretch spinning, fiber treatment, filament/thread forming, etc., can solve the problems of fiber physical properties, poor stiffness of adhesive non-woven fabrics, etc., and achieve excellent thermal Adhesiveness, good stiffness, and excellent tensile fracture performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] A method for preparing sea-island fibers for thermoforming non-woven fabrics, comprising the following steps:

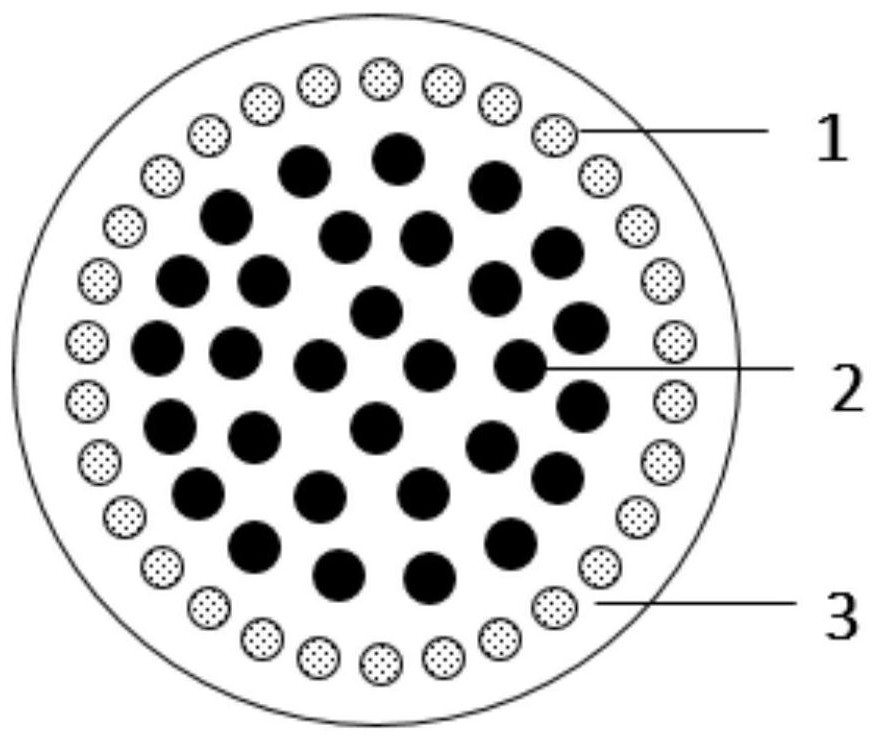

[0062] (1) Prepare island-in-the-sea fibers with a fixed island structure by composite spinning;

[0063] Raw material weight ratio is:

[0064] Outer ring island component: linear low density polyethylene with a melting point of 120°C;

[0065] Inner ring island component: nylon;

[0066] Sea component: low-density polyethylene with a melting point of 105°C;

[0067] The mass ratio of the island component and the sea component is 50:50, the outer ring island component accounts for 15wt% of the total island component, and the inner ring island component accounts for 85wt% of the total island component content;

[0068] The composite spinning process parameters are:

[0069] Spinning temperature: The temperature of the spinning screw feed zone of the sea component is 100°C, the temperature of the conveying zone is 140°C, the temperature of the melting zone ...

Embodiment 2

[0075] A method for preparing sea-island fibers for thermoforming nonwoven fabrics, comprising the following steps:

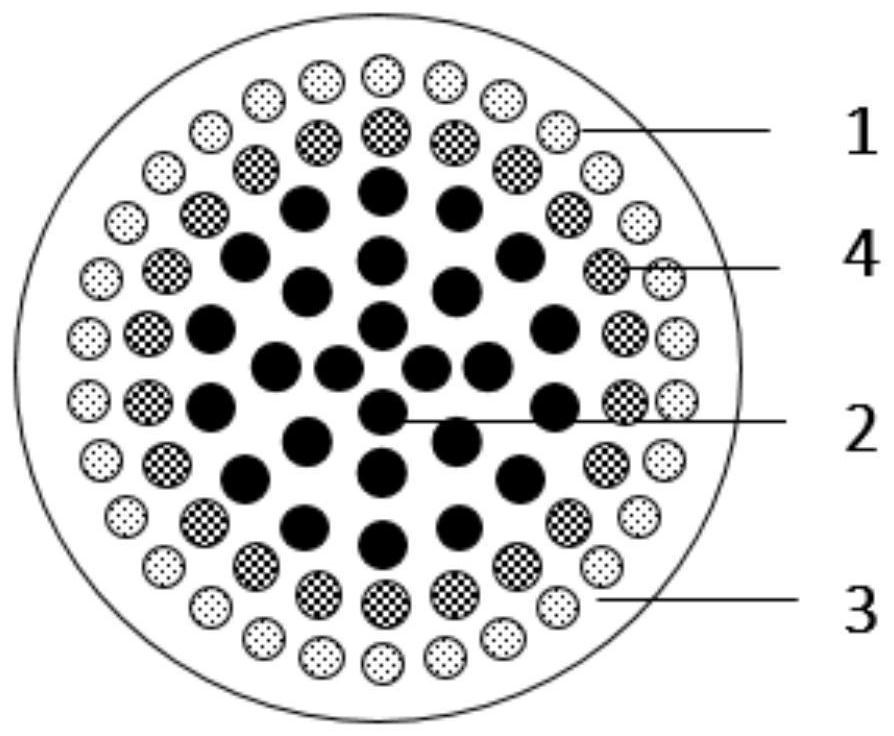

[0076] (1) Prepare island-in-the-sea fibers with a fixed island structure by composite spinning;

[0077] The weight ratio of raw materials is: the mass ratio of island component to sea component (low-density polyethylene with a melting point of 115°C) is 75:25, and the outer ring island component (linear low-density polyethylene with a melting point of 125°C) accounts for the total 5wt% of the island component; the inner ring island component accounts for 95wt% of the total island component content; the first ring inner ring island (polyester) contains PE-g-MAH (content is 2wt%); the second ring The roundabout (polyester) does not contain PE-g-MAH; the third inner roundabout (polyester) does not contain PE-g-MAH; the fourth inner roundabout (polyester) does not contain PE-g-MAH;

[0078] The composite spinning process parameters are:

[0079] Spinning temperat...

Embodiment 3

[0085] A method for preparing sea-island fibers for thermoforming non-woven fabrics, comprising the following steps:

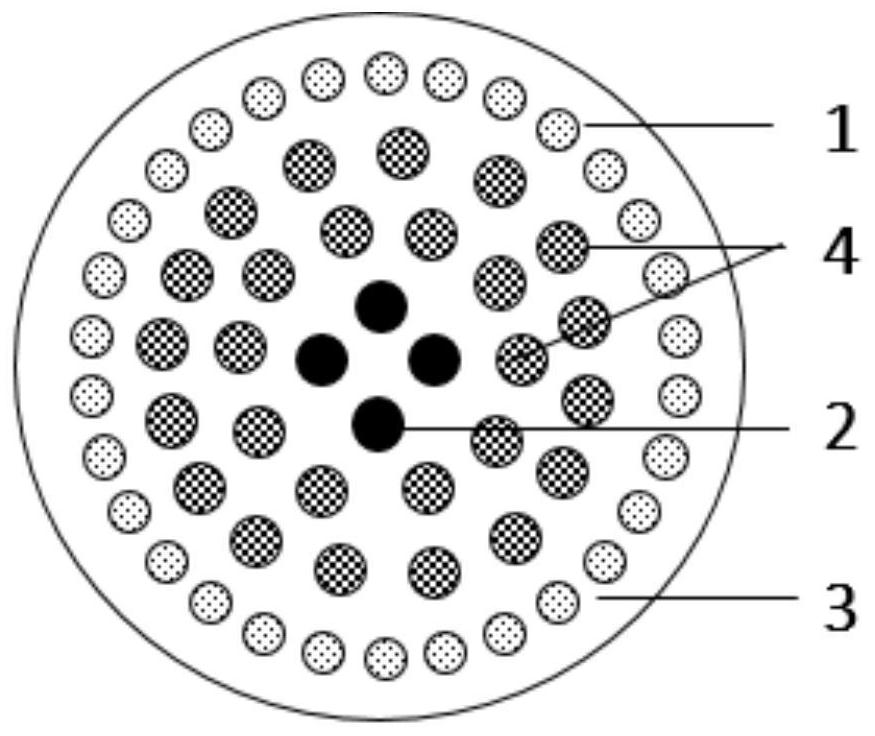

[0086] (1) Prepare island-in-the-sea fibers with a fixed island structure by composite spinning;

[0087] The weight ratio of raw materials is: the mass ratio of island component to sea component (low-density polyethylene with a melting point of 105°C) is 65:35, and the outer ring island component (linear low-density polyethylene with a melting point of 125°C) accounts for the total 10wt% of the island component; the inner ring island component accounts for 90wt% of the total island component content; the first ring inner ring island (nylon) contains PE-g-MAH (content is 5wt%); the second ring inner ring island (Nylon) contains PE-g-MAH (the content is 5wt%); the third inner ring island (Nylon) does not contain PE-g-MAH;

[0088] The composite spinning process parameters are:

[0089] Spinning temperature: The temperature of the spinning screw feed zone of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Modulus | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com