Rapid repairing method for asphalt pavement

A fast technology for asphalt pavement, applied in the direction of roads, roads, pavement details, etc., can solve the problems of not being able to enhance the strength of the newly repaired pavement, and not considering reflection cracks, etc., to achieve the purpose of enhancing the strength of the newly repaired road surface, avoiding reflection cracks, and fast operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Take the treatment of transverse cracks on a roadway as an example.

[0073] Determine the depth and width of the groove according to the width of the crack:

[0074] Crack width ≤ 3mm, groove depth is the thickness of the asphalt mixture in the surface layer, that is, 5cm, then the depth of the repair groove is 5cm, the opening width of the repair groove is 5cm, and the repair groove is V-shaped.

[0075] Adjust the slotting machine so that the depth of the repaired groove is 5cm, and the opening width of the repaired groove is 5cm. Referring to the crack tracker, drag the slotting machine by hand to slot along the crack. After the slotting is completed, blow the crack with a blower to form a repair. groove.

[0076] The modified emulsified asphalt is SBS modified emulsified asphalt, and the amount of SBS modified emulsified asphalt is about 0.5kg / m 2 , and evenly apply it on the blown slot to repair the side wall of the slot, and use sand frying equipment to mix the...

Embodiment 2

[0083] Take the treatment of transverse cracks on a roadway as an example.

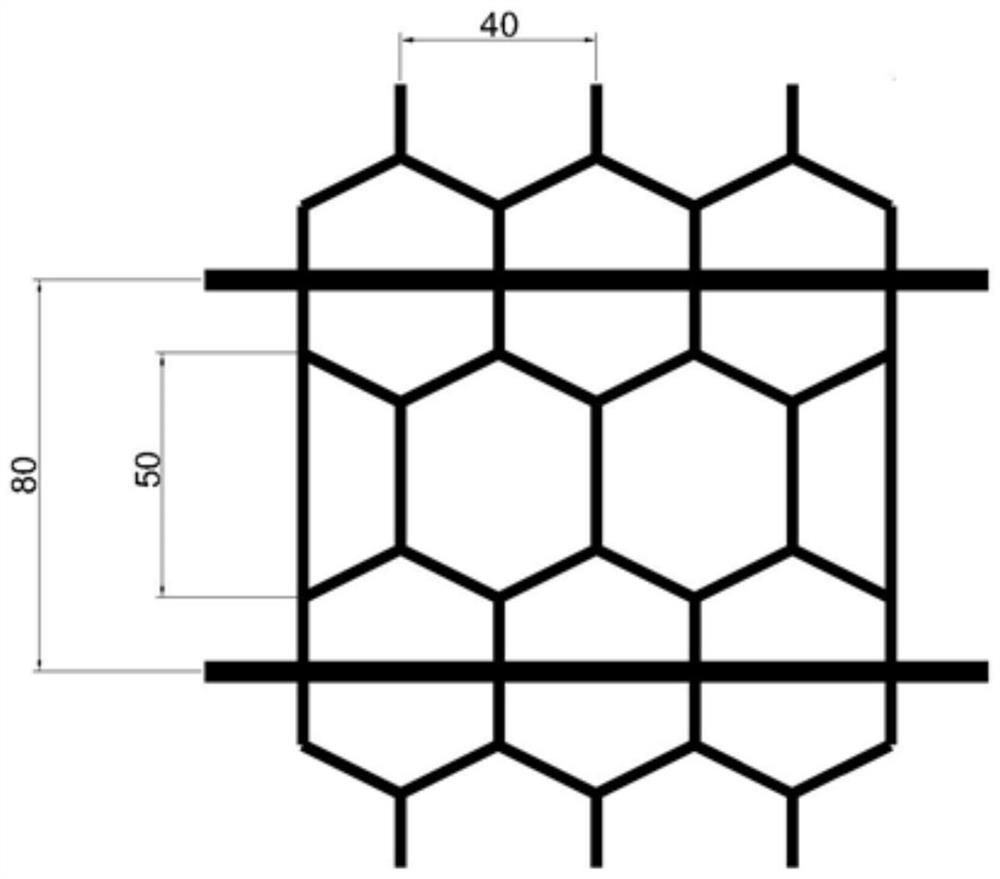

[0084] The pavement reinforcement mesh is figure 1 The pavement reinforced mesh shown, wherein the pavement reinforced mesh includes a hexagonal double-stranded steel mesh with a mesh design specification of 40×50mm and steel bars fixed on the hexagonal double-stranded metal mesh; The diameter of the steel wire of the hexagonal twisted metal mesh is 2.4mm; the diameter of the steel bar is 4.4mm.

[0085] Determine the depth of the groove and the width of the reinforced mesh according to the width of the crack:

[0086] Crack width > 3mm and < 5mm, the groove depth is the thickness of the upper layer asphalt mixture (5cm) and the middle layer asphalt mixture (6cm), which is 11cm, then the depth of the repair groove is 11cm, and the opening width of the repair groove is 11cm, The width of the reinforced mesh is 6cm, and it is laid between the surface layer and the middle surface layer, and the repair...

Embodiment 3

[0097] Take the treatment of transverse cracks on a roadway as an example.

[0098] The pavement reinforcement mesh is figure 1 The pavement reinforced mesh shown, wherein the pavement reinforced mesh includes a hexagonal double-stranded steel mesh with a mesh design specification of 40×50mm and steel bars fixed on the hexagonal double-stranded metal mesh; The diameter of the steel wire of the hexagonal twisted metal mesh is 2.4mm; the diameter of the steel bar is 4.4mm.

[0099] Determine the depth of the groove and the width of the reinforced mesh according to the width of the crack:

[0100] Crack width ≥ 5mm, groove depth is the total thickness of the asphalt layer, which is 18cm, then the depth of the repair groove is 18cm, the opening width of the repair groove is 18cm, and the width of the reinforced mesh is 7cm, which is laid between the middle surface layer and the lower layer. The repair groove is V-shaped. Wherein, the thickness of the upper layer of the asphalt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Crack width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com